Dec . 20, 2024 06:09 Back to list

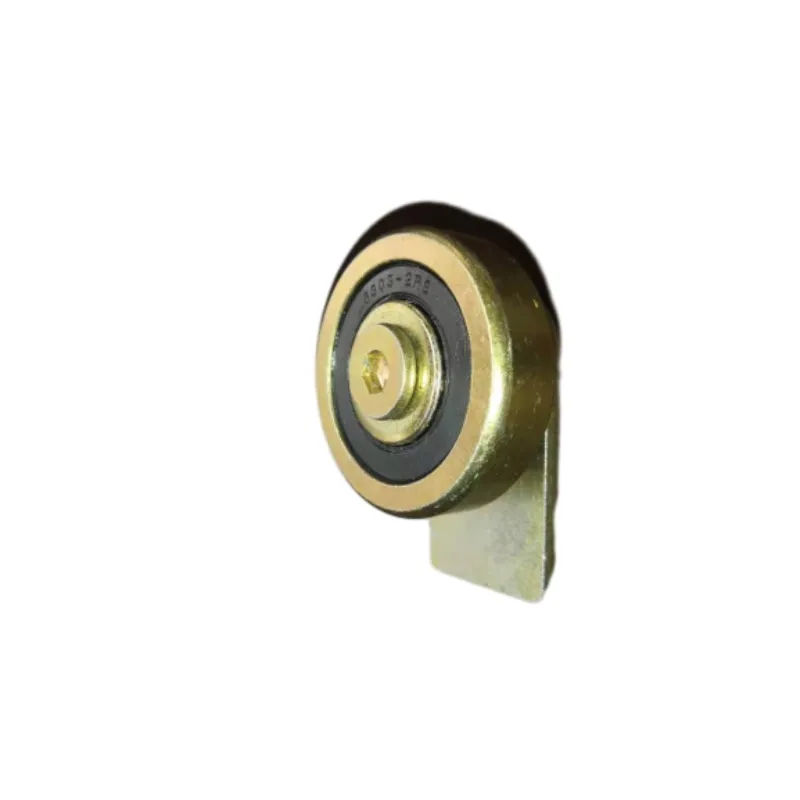

double row deep groove ball bearing

Double Row Deep Groove Ball Bearings An Overview

Double row deep groove ball bearings are a pivotal component in various mechanical applications. They are widely utilized in industries ranging from automotive to aerospace, due to their robustness and efficiency. This article delves into the characteristics, advantages, applications, and maintenance of double row deep groove ball bearings.

Understanding Double Row Deep Groove Ball Bearings

The fundamental design of a double row deep groove ball bearing consists of two rows of balls that are housed in a single outer ring and two inner rings. This configuration allows for greater load-carrying capacity and improved stability. The deep groove design means that the ball tracks are deeper than those found in standard bearings, which accommodates higher radial and axial loads.

One of the standout features of double row deep groove ball bearings is their ability to operate efficiently at high speeds. The design minimizes friction and reduces thermal buildup during operation, contributing to a longer operational life. Additionally, these bearings can accommodate slight misalignments, making them more versatile in applications where precise alignment is challenging.

Advantages of Double Row Deep Groove Ball Bearings

1. High Load Capacity Because of their unique design, double row deep groove ball bearings can handle substantial radial and axial loads. This makes them ideal for heavy-duty applications.

2. Versatility These bearings are suitable for various applications, including electrical motors, gearboxes, construction machinery, and more.

3. Durability With proper maintenance, double row deep groove ball bearings can withstand harsh operational conditions. Their robust construction makes them resistant to wear and capable of functioning in high-stress environments.

5. Enhanced Performance The design permits smoother operation with reduced noise levels, leading to improved overall machinery performance.

Applications of Double Row Deep Groove Ball Bearings

These bearings find extensive use in multiple industries

double row deep groove ball bearing

- Automotive In automotive applications, they are often used in wheel hubs, engines, and transmission systems, where they support both radial and axial loads.

- Industrial Machinery Their reliability and robustness make them ideal for conveyor systems, pumps, and fans, where continuous operation is mandatory.

- Home Appliances Electromotor-driven devices like washing machines and refrigerators frequently utilize these bearings due to their efficiency and longevity.

- Aerospace In the aerospace sector, double row deep groove ball bearings are implemented in various critical components, contributing to safety and reliability in flight operations.

Maintenance Tips

To ensure the longevity and performance of double row deep groove ball bearings, regular maintenance is essential. Here are a few tips

- Regular Inspection Periodically check for signs of wear or damage. Look for unusual noises or vibrations during operation, which may indicate a problem.

- Lubrication Ensure that the bearings are adequately lubricated. Depending on the application, choose the appropriate lubricant to prevent overheating and reduce friction.

- Cleaning Keep the surrounding environment clean to avoid the ingress of contaminants that could impair performance.

- Proper Installation Follow manufacturer guidelines for installation to prevent misalignment, which can lead to premature bearing failure.

Conclusion

Double row deep groove ball bearings play a crucial role in modern machinery, offering durability, efficiency, and versatility across various applications. Their ability to handle high loads, along with reduced maintenance requirements, makes them a preferred choice for engineers and manufacturers alike. Understanding their features, advantages, and maintenance needs can lead to enhanced performance and longevity in machinery, contributing significantly to operational success.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025