Nov . 01, 2024 19:18 Back to list

Double Row Angular Contact Ball Bearings Product Guide and Specifications

Double Row Angular Contact Ball Bearings An Overview

Double row angular contact ball bearings are critical components in various industrial applications, providing essential support and reducing friction between moving parts. These bearings are designed to accommodate both axial and radial loads, making them suitable for high-performance environments.

Design Characteristics

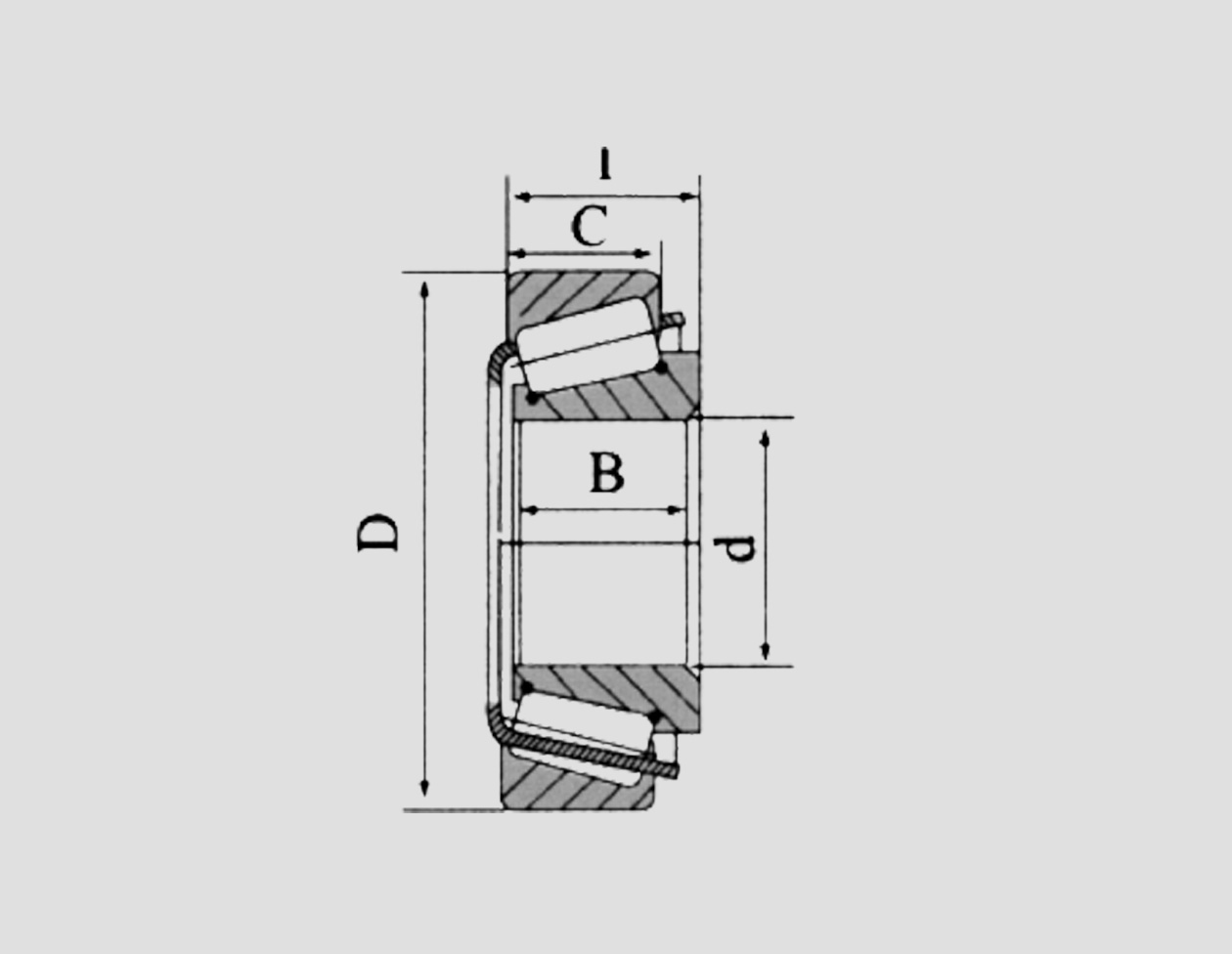

The distinctive feature of double row angular contact ball bearings is their geometry, which allows them to handle loads from multiple directions. This is achieved through the arrangement of the balls in two rows, each oriented at an angle to the bearing axis. This configuration enables the bearing to support axial loads in both directions, making it an ideal choice for applications where such loads are prevalent.

These bearings are typically constructed from high-quality materials, ensuring durability and robustness. Commonly used materials include high carbon chrome steel, stainless steel, and bearing bronze, each selected for their specific mechanical properties and resistance to wear. The inner and outer rings of these bearings are precisely machined to enhance performance and reliability.

Applications

Double row angular contact ball bearings find extensive use in a variety of industries. They are commonly employed in the automotive sector for wheel hubs, steering mechanisms, and transmission systems. In the aerospace industry, these bearings are used in landing gear and engine components, where load capacity and reliability are critical.

In addition, they are utilized in manufacturing equipment, such as gearboxes, pumps, and motors. The ability to handle combined loads makes them highly suitable for these applications, where both axial and radial forces are at play. Other notable applications include electric machines, agricultural machinery, and various construction equipment.

double row angular contact ball bearing catalogue

Advantages

The advantages of double row angular contact ball bearings are considerable. Their ability to support high radial and axial loads without compromising on performance is a key benefit, contributing to increased operational efficiency. Their design also leads to reduced overall frictional losses, which translates to lower energy consumption and heat generation.

Furthermore, double row angular contact ball bearings excel in handling misalignments. This capacity allows for easier installation and maintenance, as it can accommodate slight shaft misalignments, reducing the risk of premature failure. This reliability is a significant advantage in demanding environments where downtime can be costly.

Maintenance and Care

While double row angular contact ball bearings are robust, regular maintenance is essential to ensure longevity. Proper lubrication is crucial; it helps reduce friction and wear, extending the bearing's lifespan. Careful monitoring of the operating environment, including temperature and load conditions, can also help in identifying potential issues before they lead to failure.

Conclusion

In summary, double row angular contact ball bearings are indispensable components in many mechanical systems. Their unique design, adaptability to different load conditions, and durability make them a popular choice in various industries. As technology continues to advance, the demand for these bearings is likely to grow, highlighting their importance in the future of engineering and manufacturing. Ensuring proper maintenance and selecting the right bearing for specific applications will be key to maximizing their benefits and ensuring optimal performance.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025