Dec . 05, 2024 15:01 Back to list

difference between deep groove ball bearing and ball bearing

The Difference Between Deep Groove Ball Bearings and Standard Ball Bearings

Bearings are crucial components used in various mechanical applications to reduce friction and facilitate smoother motion between moving parts. Among the different types of bearings, deep groove ball bearings and standard ball bearings are widely recognized for their efficiency and versatility. While they serve similar functions, there are distinct differences that cater to varying operational needs. This article delineates the key differences between deep groove ball bearings and standard ball bearings, elucidating their unique features, applications, and advantages.

1. Structure and Design

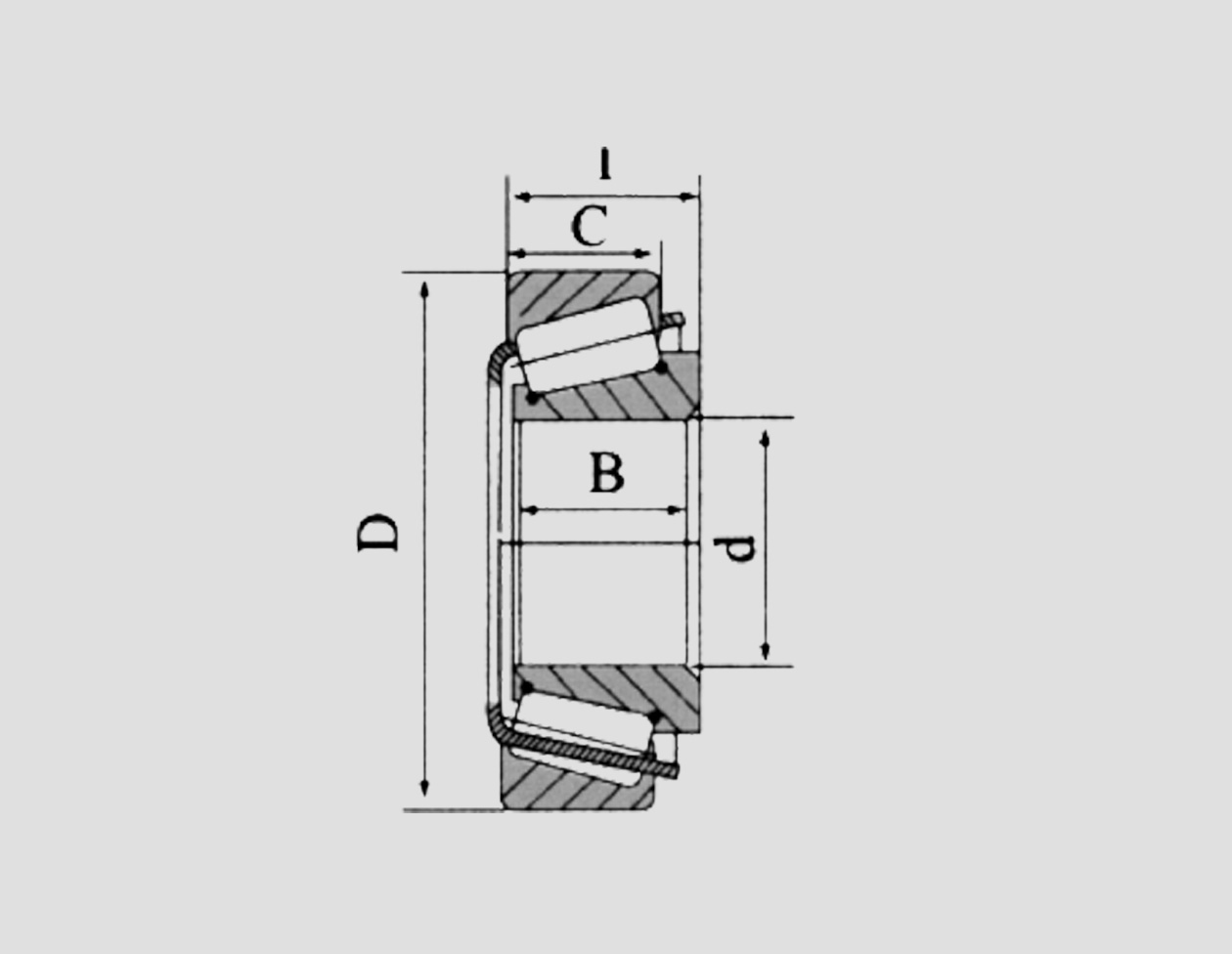

The most prominent difference lies in the structure and design of the bearings. Deep groove ball bearings are characterized by their deep raceway grooves that allow them to accommodate not only radial loads but also axial loads in both directions. This design feature makes them generally more versatile compared to standard ball bearings, which typically only handle radial loads and offer limited axial load capacity.

The raceway in deep groove bearings is significantly deeper, which provides more contact surface area for the balls during operation. This greater contact area offers increased load-carrying capacity and enhances the bearing's ability to manage heavy loads and high speeds, making them suitable for applications with rigorous operational demands.

2. Load Capacity

Deep groove ball bearings boast a higher load capacity compared to standard ball bearings

. This is primarily due to the design of the deep raceway, which allows them to carry larger radial and axial forces effectively. Standard ball bearings, in contrast, are more limited in this aspect and may not perform optimally when faced with heavy loads or situations requiring support for multidirectional forces.As a result, deep groove ball bearings are often the preferred choice in high-load or dynamic environments, such as in electric motors, conveyor systems, and automotive applications. Standard ball bearings, while still useful, are more commonly found in lighter applications where high load and speed capacities are not necessary.

difference between deep groove ball bearing and ball bearing

3. Speed and Performance

When it comes to speed, deep groove ball bearings excel due to their design, which minimizes friction during operation. The deep raceway grooves allow for smoother rolling of the balls and result in lower operating temperatures. This trait not only enhances their durability but also ensures a longer service life, especially in high-speed applications.

In contrast, standard ball bearings may experience higher friction levels due to their shallower raceways, which can lead to increased wear and reduced efficiency over time. Therefore, for applications requiring high rotational speeds and longevity, deep groove ball bearings are generally favored.

4. Versatility and Applications

Deep groove ball bearings are extremely versatile and applicable in a wide range of industries, including automotive, aerospace, agriculture, and manufacturing. They are utilized in electric motors, gearboxes, and various household appliances, where their ability to handle both axial and radial loads plays a critical role.

Standard ball bearings, while less versatile, are often sufficient for simpler mechanisms. They can be found in small appliances, toys, and light machinery, where the operational demands are lower, and the design simplicity is a benefit.

Conclusion

In summary, deep groove ball bearings and standard ball bearings, while both integral to reducing friction and enhancing motion in machinery, differ significantly in design, load capacity, speed performance, and application versatility. Deep groove ball bearings are engineered for higher loads and speeds, making them suitable for more demanding environments. Standard ball bearings, on the other hand, offer simplicity and low-load handling capabilities optimal for lighter applications. Understanding these differences is essential for selecting the right type of bearing for specific mechanical needs, ensuring optimal performance and longevity in various applications.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025