Aug . 10, 2024 19:50 Back to list

Design and Application of Axial Ball Thrust Bearings in Industrial Machinery Systems

Axial Ball Thrust Bearings An Overview

Axial ball thrust bearings play a crucial role in various mechanical applications where axial loads must be managed efficiently. These bearings are designed specifically to accommodate thrust (axial) loads, which are forces that act parallel to the shaft. Offering unique advantages in high-speed and heavy-load environments, axial ball thrust bearings are essential components in many industries, including automotive, aerospace, and machinery.

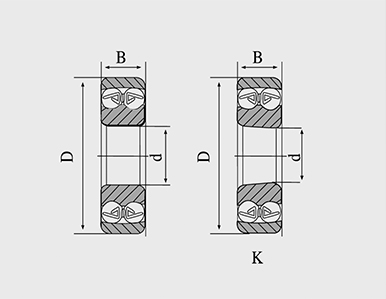

Design and Construction

Axial ball thrust bearings primarily consist of three main components the shaft washer, the housing washer, and the ball elements. The shaft washer is mounted on the rotating shaft, while the housing washer is fixed in the surrounding bore. The balls are positioned between these washers, allowing them to roll smoothly as the shaft rotates. This design minimizes friction while providing high load-carrying capacity.

These bearings are available in various materials, including steel, stainless steel, and ceramic. The choice of material can affect the bearing's performance, durability, and resistance to corrosion or wear. High-quality materials contribute to extending the lifespan of the bearing, making it a cost-effective solution in the long run.

Applications

Axial ball thrust bearings are used in a multitude of applications where axial loads are predominant. Their high-performance capabilities make them suitable for use in

1. Automotive In vehicles, axial ball thrust bearings are often found in clutches, gearboxes, and wheel hubs. They facilitate smooth operation and enhance reliability, which is crucial for safety and performance.

2. Industrial Machinery These bearings are common in conveyor systems, turbines, and cranes, where axial loads need to be controlled precisely. Their ability to handle heavy loads ensures the efficient operation of machinery in factories and other industrial settings.

axial ball thrust bearing

4. Power Tools These bearings are integral in power tools, providing stability and support while minimizing wear and tear during operation.

Advantages

One of the primary advantages of axial ball thrust bearings is their ability to accommodate high axial loads while maintaining low friction levels. This efficiency results in less energy consumption and prolonged operational life for both the bearings and the equipment they support. Additionally, their compact design allows for easier integration into various machinery, making them a versatile choice for engineers and designers.

Moreover, axial ball thrust bearings can operate effectively at various speeds, making them applicable in both low-speed and high-speed scenarios. The variety of sizes and load capacities available ensures that there is an appropriate option for almost any requirement, further enhancing their appeal across different industries.

Maintenance and Care

To ensure optimal performance and longevity, proper maintenance of axial ball thrust bearings is essential. Regular lubrication reduces friction and prevents wear, while periodic inspections can identify potential issues early. Contamination from dirt or debris can severely affect performance, making it critical to keep these bearings clean and free from foreign materials.

Conclusion

In summary, axial ball thrust bearings are vital components in many mechanical systems, providing efficient load management and minimal friction. Their unique design and ability to operate in various settings make them indispensable in numerous industries. As technology advances, the development of even more durable materials and innovative designs will likely enhance the capabilities of axial ball thrust bearings, making them even more efficient and reliable in the future. Whether in automotive applications, industrial machinery, or aerospace, their importance cannot be overstated.

Latest news

-

Industrial Machine Bearings: the core hub of mechanical operation

NewsAug.06,2025

-

Deep Groove Ball Bearing: A Dynamic "Elf" Operating Mechanically

NewsAug.06,2025

-

Compact craftsmanship: the way to optimize the space of Concrete Mixer Bearings

NewsAug.06,2025

-

Combine Harvester Bearings: The 'Steel Backbone' of Modern Agriculture

NewsAug.06,2025

-

Bearing Machinery: a flexible support hub for mechanical operation

NewsAug.06,2025

-

Agricultural Equipment Bearings: A Power Hub for Intensive Cultivation under Radial Space Constraints

NewsAug.06,2025