Dec . 12, 2024 06:07 Back to list

deep groove ball bearing sizes

Understanding Deep Groove Ball Bearing Sizes A Comprehensive Guide

Deep groove ball bearings are one of the most widely used types of bearings in various industrial applications and machinery. Their popularity stems from their versatility, simplicity, and ability to accommodate both radial and axial loads. This article explores the sizes of deep groove ball bearings, their specifications, and the factors to consider when selecting the right size for a specific application.

What Are Deep Groove Ball Bearings?

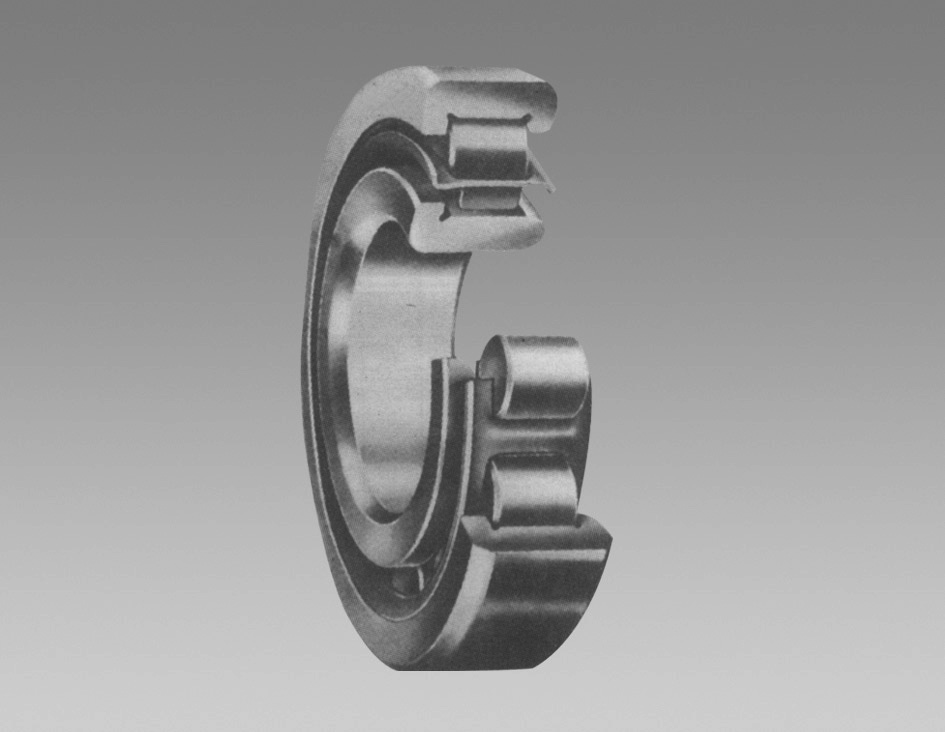

Deep groove ball bearings consist of an inner ring, an outer ring, and a set of balls that are housed within the raceways of these rings. The design allows for smoother rotation and reduced friction, making them ideal for applications that require high-speed operation. These bearings come in various sizes, which are determined primarily by their dimensions and load capacity.

Standard Sizes of Deep Groove Ball Bearings

Deep groove ball bearings are classified by their dimensions, typically represented by the ISO (International Organization for Standardization) standard. The size specifications include the inner diameter (ID), outer diameter (OD), and width (B) of the bearing. Common sizes can be represented in a format like this 6201 (where 62 refers to the series, 0 indicates a metric bearing, and 1 specifies the bore size).

- Inner Diameter (ID) This is the diameter of the hole through the center of the bearing. Typical inner diameter sizes range from as small as 4 mm to as large as 250 mm or more. - Outer Diameter (OD) This is the diameter of the outer ring. These typically range from 8 mm to 350 mm or greater. - Width (B) The width of the bearing plays a critical role in its capacity. Width can vary from 2.5 mm to over 70 mm.

The most common series of deep groove ball bearings include 6000, 6200, 6300, and many others, where the first two digits denote the type, and the final digits generally indicate the specific size within that category.

Factors Influencing Bearing Size Selection

deep groove ball bearing sizes

Selecting the right size of deep groove ball bearings for your application involves several considerations

1. Load Requirements Evaluate the radial and axial loads that the bearing will encounter. Each bearing has a specified load rating, and exceeding this can lead to premature failure.

2. Speed Ratings Deep groove ball bearings are designed to operate at specific RPMs. It's crucial to select a bearing that can withstand the operating speed without excessive heat generation or wear.

3. Temperature Operating temperatures can affect the selection of materials and lubricants used in the bearings, which can also influence bearing size and type.

4. Space Constraints Ensure that the selected bearing fits within the spatial requirements of the application, as physical space limitations may restrict the allowable size.

5. Sealing Requirements Depending on the environment in which the bearing will operate, additional sealing may be required. Sealed or shielded bearings will often have different dimensional characteristics compared to open bearings.

Conclusion

Deep groove ball bearings are essential components in countless machines and devices, providing smooth motion and support. Understanding the various sizes and specifications is crucial for engineers and designers to select the most appropriate bearing for their specific needs. By considering load requirements, speed, temperature, space constraints, and sealing options, one can ensure optimal performance and longevity of the bearing within its application.

With the right selection and implementation, deep groove ball bearings can significantly enhance efficiency and functionality in a myriad of mechanical systems. Whether in automotive applications, industrial machinery, or everyday household items, these bearings play a pivotal role in ensuring seamless operation.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025