Dec . 05, 2024 14:06 Back to list

Deep Groove Ball Bearings Size Guide for Optimal Performance and Applications

Understanding Deep Groove Ball Bearing Sizes

Deep groove ball bearings are among the most common types of bearings used in various mechanical applications, ranging from electric motors to automotive components. These bearings are designed to support both radial and axial loads, making them versatile and widely applicable. One key aspect that engineers and designers must consider when selecting deep groove ball bearings is their sizes, which play a critical role in the bearing's performance and suitability for specific applications.

What are Deep Groove Ball Bearings?

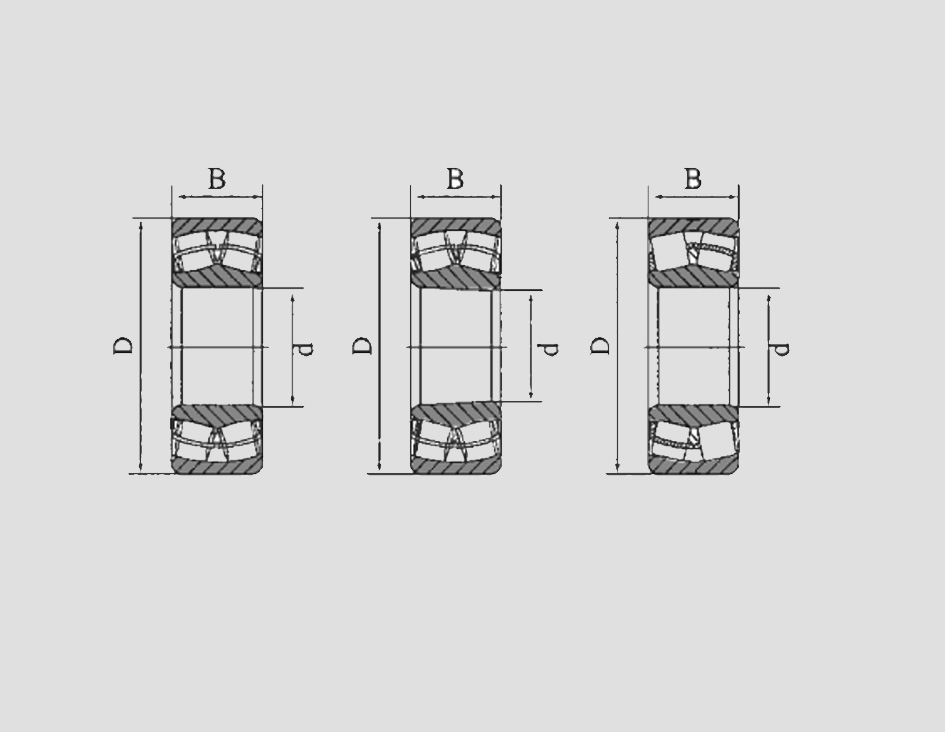

Deep groove ball bearings consist of an outer ring, an inner ring, a set of balls, and a cage that holds the balls in position. The design features deep grooves in both the inner and outer rings, allowing for a larger contact area between the balls and the rings. This design facilitates the accommodation of higher radial and axial loads compared to other bearing types. Additionally, this bearing type exhibits low friction, high speed capability, and durability, making it a popular choice in various machinery.

Importance of Size

The size of a deep groove ball bearing is defined by several key dimensions the inner diameter (ID), the outer diameter (OD), and the width (W). These measurements are crucial as they determine how the bearing fits within its housing and interacts with the shaft. Selecting the correct size is essential for ensuring the bearing operates effectively and has a long service life. A bearing that is too small may fail under load, while one that is too large may not fit properly, leading to mechanical issues and potential failure.

Common Sizing Standards

Deep groove ball bearings come in a variety of standardized sizes, which simplifies the selection process for engineers and purchasers. The International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) provide guidelines for bearing sizes, ensuring uniformity across manufacturers. Typically, ISO metric deep groove ball bearings are available in sizes ranging from 10 mm to over 1,200 mm in outer diameter, while inner diameters usually range from 5 mm to 700 mm.

deep groove ball bearing sizes

Common sizes include

- 62201 12 mm ID, 32 mm OD, 10 mm W - 6203 17 mm ID, 40 mm OD, 12 mm W - 6305 25 mm ID, 62 mm OD, 17 mm W

These specifications are integral when choosing the right bearing for specific applications.

Selecting the Right Size

When choosing a deep groove ball bearing, it’s essential to assess the operational conditions, including load type, speed, and environmental factors. For instance, in high-speed applications, the bearing size should be optimized to minimize friction. In contrast, heavy load applications may require larger bearings or those designed with reinforced structures.

Additionally, tolerance levels must also be accounted for. Bearings are available in various tolerance classes, such as P0 (normal), P6 (precision), and P5 (high precision), which can affect their performance depending on the specific application requirements.

Conclusion

Understanding the sizes of deep groove ball bearings is critical for anyone involved in mechanics or engineering. With a wide range of standard sizes and industrial applications, selecting the right bearing is paramount to ensuring optimal performance and durability. By considering the dimensions, load capacities, and operational requirements, engineers can make informed decisions that enhance the reliability of their systems. Consequently, deep groove ball bearings remain a cornerstone in the realm of mechanical engineering, thanks to their adaptability and efficiency in various applications.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025