Nov . 10, 2024 07:24 Back to list

Design Overview of Deep Groove Ball Bearing Technical Specifications and Applications

Understanding Deep Groove Ball Bearings A Comprehensive Overview

Deep groove ball bearings are a crucial component in various mechanical systems, facilitating efficient motion and reducing friction. This article delves into the design, functionality, and applications of deep groove ball bearings, providing insights into their importance in modern engineering.

The Design of Deep Groove Ball Bearings

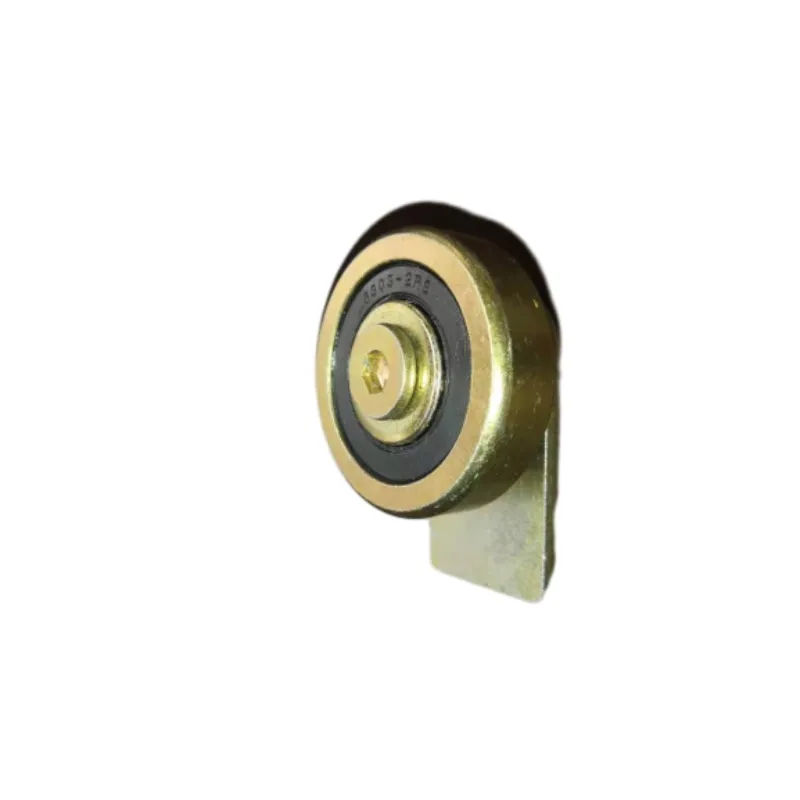

Deep groove ball bearings consist of an outer ring, an inner ring, a cage (or separator), and a set of spherical balls. The inner ring has an inner diameter that allows it to fit snugly onto a shaft, while the outer ring has an outer diameter that provides a stable fit within a housing. The balls are located in the raceways of both the inner and outer rings, which are designed with a deeper groove than standard ball bearings. This design feature allows for greater radial and axial load-carrying capacity, making them suitable for various applications.

The materials used in manufacturing deep groove ball bearings are typically high-carbon chromium steel, stainless steel, or ceramic, depending on the required performance characteristics such as corrosion resistance, durability, and temperature resistance. The choice of material directly affects the bearing's lifespan, performance, and suitability for specific environments.

How Deep Groove Ball Bearings Work

The functionality of deep groove ball bearings hinges on the principles of rolling motion. When a load is applied to the bearing, the spherical balls roll between the inner and outer rings, minimizing friction and wear. This rolling action differs significantly from sliding motion, as it reduces surface contact, leading to lower energy losses and improved efficiency.

Deep groove ball bearings can accommodate both radial and axial loads. The deeper raceway grooves enable them to handle higher stresses and maintain stability under dynamic conditions. As such, they are widely employed in applications where both types of loads are present, such as in electric motors, pumps, and automotive engines.

Applications of Deep Groove Ball Bearings

The versatility of deep groove ball bearings is evident in their extensive range of applications

. Here are some key sectors where they are commonly useddeep groove ball bearing drawing

1. Automotive Industry Deep groove ball bearings are found in various automotive components, including wheel hubs, steering systems, and transmissions. Their ability to support high speeds and significant loads makes them ideal for these applications.

2. Industrial Machinery In manufacturing equipment, deep groove ball bearings are used in conveyor systems, rotating shafts, and other critical machinery. Their reliability contributes to the overall efficiency of industrial operations.

3. Household Appliances Many household appliances, such as washing machines, refrigerators, and vacuum cleaners, integrate deep groove ball bearings to facilitate smooth operation and reduce noise levels.

4. Electronics From computer hard drives to electric motors in home devices, deep groove ball bearings play a pivotal role in ensuring longevity and performance in the electronics sector.

Advantages of Deep Groove Ball Bearings

The popularity of deep groove ball bearings can be attributed to several advantages

- High Versatility They can handle a wide range of speeds and loads, making them suitable for various applications. - Durability Their robust design and material choices contribute to a long service life, reducing the need for frequent replacements. - Ease of Maintenance Deep groove ball bearings often require minimal maintenance, which can save time and resources for operators.

Conclusion

Deep groove ball bearings are integral to modern machinery and technology. Their unique design and functionality make them indispensable in a wide variety of applications, from automotive to industrial and household uses. Understanding the principles behind their operation and advantages can help engineers and technicians make informed decisions when selecting bearings for specific applications, ultimately leading to more efficient and reliable systems.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025