Sep . 04, 2024 10:20 Back to list

deep groove ball bearing function

The Functionality of Deep Groove Ball Bearings

Deep groove ball bearings are one of the most commonly used types of bearings in various mechanical applications. They are characterized by their deep raceway grooves which enable them to accommodate both radial and axial loads. This versatility renders them indispensable in a myriad of industries, from automotive to aerospace, and even household appliances.

The primary function of deep groove ball bearings is to reduce friction between rotating parts, thereby facilitating smooth and efficient motion. When a shaft rotates, the bearing supports it, permitting it to turn with minimal resistance. This characteristic is crucial in enhancing the overall efficiency of machinery, as lower friction translates to less energy consumption and increased lifespan of the components involved.

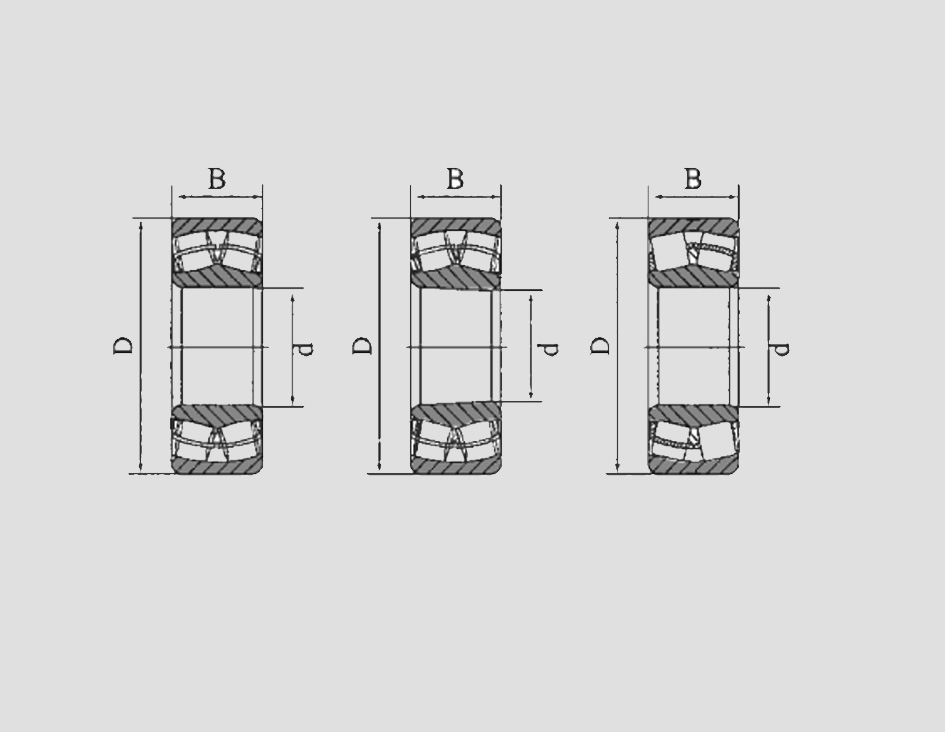

In terms of design, deep groove ball bearings consist of an inner ring, an outer ring, a set of balls, and a cage that holds the balls in place. The deep raceways allow for a larger number of balls to be installed, which increases load capacity and helps distribute loads evenly across the bearing. The geometry of these bearings allows them to handle a combination of radial and axial forces, making them suitable for applications where both types of loads are present.

deep groove ball bearing function

Moreover, deep groove ball bearings are available in a variety of materials, including stainless steel, carbon steel, and ceramic, which provides options for different environments and performance requirements. For instance, stainless steel bearings are often used in corrosive environments where resistance to rust and oxidation is essential.

The operational efficiency of deep groove ball bearings can be enhanced with the use of lubricants. Proper lubrication reduces friction and wear between the moving parts, prolonging the service life of the bearings. Various types of lubricants are available, including grease and oil, depending on the operational conditions and the specific needs of the application.

In summary, deep groove ball bearings serve a pivotal role in various mechanical systems by facilitating smooth motion and reducing friction. Their design allows them to handle both radial and axial loads, making them versatile for numerous applications. With a variety of materials and lubrication options, these bearings can be tailored to meet the demands of specific environments. As technology continues to advance, deep groove ball bearings will remain a critical component in the development of efficient and reliable machinery across multiple sectors.

Latest news

-

Industrial Machine Bearings: the core hub of mechanical operation

NewsAug.06,2025

-

Deep Groove Ball Bearing: A Dynamic "Elf" Operating Mechanically

NewsAug.06,2025

-

Compact craftsmanship: the way to optimize the space of Concrete Mixer Bearings

NewsAug.06,2025

-

Combine Harvester Bearings: The 'Steel Backbone' of Modern Agriculture

NewsAug.06,2025

-

Bearing Machinery: a flexible support hub for mechanical operation

NewsAug.06,2025

-

Agricultural Equipment Bearings: A Power Hub for Intensive Cultivation under Radial Space Constraints

NewsAug.06,2025