Nov . 05, 2024 00:54 Back to list

cylindrical roller bearing specifications

Cylindrical Roller Bearing Specifications An Overview

Cylindrical roller bearings are crucial components in various industrial applications, offering high load-carrying capabilities and enhanced mechanical performance. These bearings are essential in machinery ranging from electric motors to automotive applications. Understanding the specifications of cylindrical roller bearings is vital for ensuring their optimal selection and performance in specific applications.

1. Design and Structure

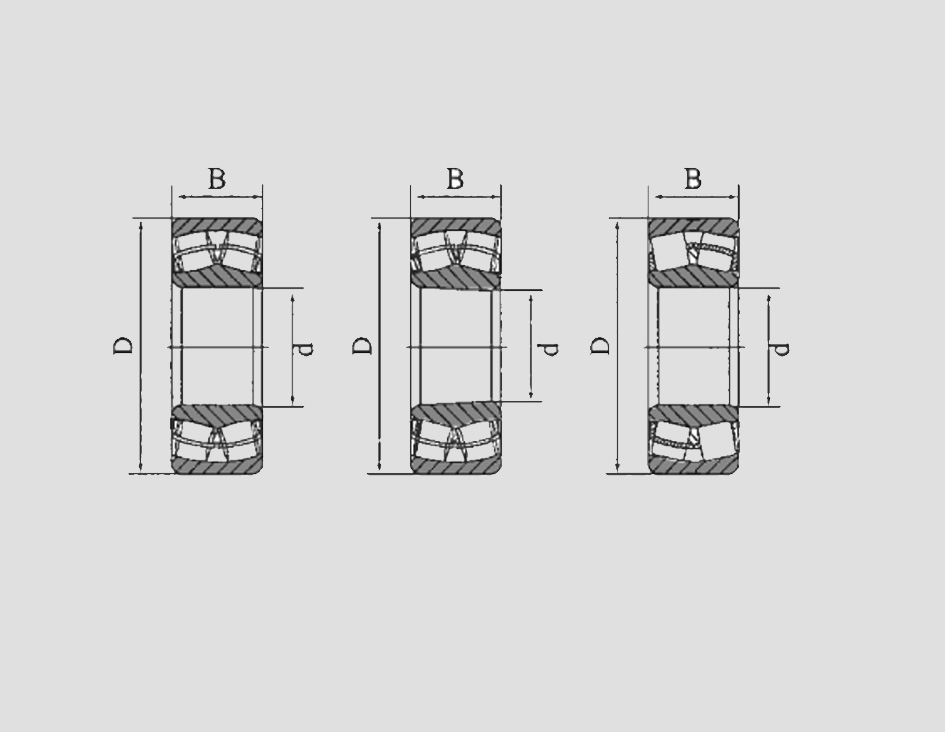

Cylindrical roller bearings consist of cylindrical rollers arranged between an inner and outer ring. Unlike ball bearings, which have a point contact, cylindrical roller bearings provide line contact, enabling them to carry heavier radial loads while minimizing friction and wear. The number of rollers, their diameter, and the spacing play a crucial role in the bearing's capacity and load distribution features.

2. Dimensions and Tolerances

The dimensions of cylindrical roller bearings are specified by standardized metrics. The bore size, outer diameter, width, and clearance are crucial dimensions that determine the fit and operation of the bearing within machinery. Standard tolerances are established by organizations such as ISO and ABEC, ensuring interchangeability and consistent performance. Tolerances can vary based on the bearing type and application, impacting the assembly process and operational efficiency.

3. Load Ratings

Cylindrical roller bearings are characterized by their dynamic and static load ratings. The dynamic load rating (C) signifies the maximum load a bearing can handle while in motion, while the static load rating (C0) denotes the maximum load when stationary. These ratings are essential for predicting the lifespan and operational stability of the bearing under specific loading conditions. Factors such as speed, temperature, and lubrication also influence the bearing's load capacity and longevity.

4. Types of Cylindrical Roller Bearings

There are several types of cylindrical roller bearings, each designed for specific applications. Some common types include

- N-type This type has a rib on the outer ring, allowing axial displacement of the roller assembly, which is beneficial in applications with thermal expansion

.cylindrical roller bearing specifications

- NU-type Similar to N-type, but with the rib only on the outer ring, allowing the inner ring to be free for axial movement.

- NJ-type This variation has ribs on both rings, enabling it to handle axial loads in one direction.

- NF-type This type has a rib on the inner ring only, mainly used for applications that require alignment adjustments.

Understanding the differences between these types assists engineers in selecting the appropriate bearing for their design requirements.

5. Lubrication and Maintenance

Proper lubrication is crucial for the performance and longevity of cylindrical roller bearings. Lubricants reduce friction, dissipate heat, and prevent wear between moving components. Various lubrication methods—such as grease, oil, and advanced synthetic lubricants—are employed based on the operating conditions. Regular maintenance checks, including monitoring for signs of wear, misalignment, and lubrication levels, are essential to maintain bearing integrity.

6. Performance and Applications

Cylindrical roller bearings are extensively utilized in various sectors, including automotive, aerospace, and manufacturing. They are commonly found in gearboxes, pumps, electric motors, and industrial machines. The high load capacity, operational reliability, and ability to handle misalignment make them ideal for heavy-duty applications.

7. Conclusion

Choosing the right cylindrical roller bearing is critical for ensuring optimal performance in machinery and equipment. Understanding their specifications—such as dimensions, load ratings, and lubrication requirements—is essential for engineers and technicians involved in the design and maintenance of mechanical systems. By selecting appropriate bearings based on application needs and adhering to best practices in lubrication and maintenance, users can enhance their machinery's operational efficiency and reliability, ensuring prolonged service life and reduced downtime.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025