Dec . 18, 2024 11:24 Back to list

concrete mixer drum bearing

Understanding Concrete Mixer Drum Bearings Importance, Types, and Maintenance

Concrete mixer drums play an integral role in the construction industry, acting as the vessel that mixes cement, water, and aggregates to create concrete. An essential component of these drums is the bearing system, which supports the rotating drum and enables efficient mixing. This article will explore the importance of concrete mixer drum bearings, the types available, and maintenance practices to ensure their longevity.

Importance of Concrete Mixer Drum Bearings

The primary function of concrete mixer drum bearings is to reduce friction between moving parts, allowing the drum to rotate smoothly. This is critical for achieving a homogeneous mixture of concrete. Any malfunction in the bearing system can lead to uneven mixing, resulting in poor-quality concrete that may compromise the structural integrity of construction projects.

Moreover, the performance of concrete mixers directly impacts construction efficiency. A well-maintained bearing system reduces downtime and repair costs, contributing to a more streamlined workflow on job sites. Thus, investing in high-quality bearings and conducting regular maintenance is essential for enhancing the efficiency of concrete mixers and ensuring the quality of the mix.

Types of Concrete Mixer Drum Bearings

There are several types of bearings used in concrete mixer drums, each serving different applications based on size, load capacity, and environmental conditions. The most common types include

1. Ball Bearings These are the most widely used types of bearings in concrete mixers due to their ability to handle both radial and axial loads. They are characterized by their simple structure, made up of inner and outer rings with balls in between, and are suitable for standard mixing operations.

2. Roller Bearings Unlike ball bearings, roller bearings use cylindrical rollers, providing a larger contact area with the races. This design allows them to accommodate heavier loads and is ideal for larger concrete mixers or those operating under extreme conditions.

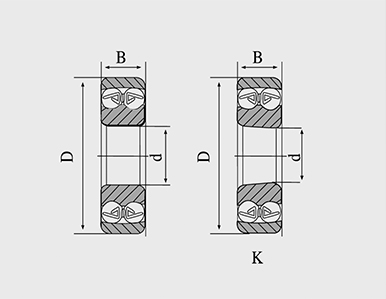

3. Spherical Bearings Spherical bearings can accommodate misalignment and are particularly useful in rugged construction environments where vibrations and shocks occur. They offer enhanced durability and a longer service life compared to standard bearings.

concrete mixer drum bearing

4. Plain Bearings Also known as bushings, plain bearings are simple sleeves that reduce friction between two moving surfaces. They are less commonly used than other types but can be found in specific applications where simplicity and cost-effectiveness are prioritized.

Maintenance Practices

Maintaining concrete mixer drum bearings is crucial for ensuring their performance and extending their lifespan. Here are some best practices

1. Regular Inspections Conduct routine checks to identify any signs of wear, damage, or misalignment. Early detection of potential issues can prevent more significant problems down the line.

2. Lubrication Bearing lubrication is essential to reduce friction and wear. Use the recommended lubricant types and follow the manufacturer’s guidelines on lubrication intervals. Over-lubrication and under-lubrication can both cause issues.

3. Cleaning Dirt and debris can obstruct bearing function, so regularly clean the bearings and surrounding areas. This practice helps in preventing premature wear and tear.

4. Temperature Monitoring Excessive heat can indicate bearing failure or misalignment. Monitor the operational temperatures and take corrective actions if they exceed permissible limits.

5. Replacement If bearings show significant signs of degradation or wear, it’s crucial to replace them promptly. Operating with faulty bearings can lead to more extensive damage to the concrete mixer and pose safety risks.

Conclusion

Concrete mixer drum bearings are vital components that play a key role in the efficiency and quality of concrete mixing operations. Understanding their types, importance, and maintenance practices can lead to enhanced performance, reduced downtime, and ultimately improved project outcomes in the construction industry. By investing in high-quality bearings and adhering to a robust maintenance regimen, operators can ensure their concrete mixers run smoothly and effectively, contributing to the success of their projects.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025