May . 06, 2025 16:21 Back to list

Concrete Mixer Drum Bearing

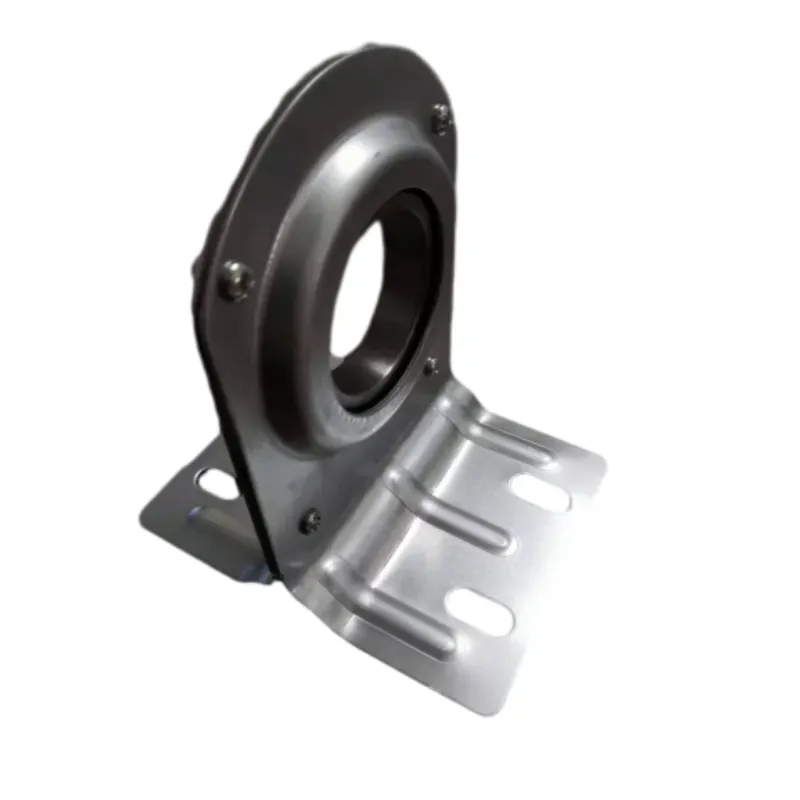

Concrete mixers are essential in construction, ensuring that large quantities of concrete are mixed thoroughly and efficiently. Among the many components that contribute to the performance of these machines, the concrete mixer drum bearing plays a crucial role. These bearings enable the drum to rotate smoothly, facilitating the mixing process. Without reliable bearings, the operation of a concrete mixer would be inefficient and prone to breakdowns, leading to costly delays and repairs.

Concrete mixer drum bearings are typically designed to handle both radial and axial loads. They are often subjected to heavy-duty conditions, including high speeds, large loads, and exposure to harsh environments, such as dust, water, and extreme temperatures. For this reason, concrete mixer drum bearings are made from high-quality materials that can withstand the stress and fatigue of regular use.

In addition to supporting the drum’s rotation, these bearings help maintain the proper alignment of the drum, ensuring that concrete is mixed uniformly. Given their critical function, choosing the right concrete mixer drum bearing is vital for ensuring the longevity and reliability of the machine. Bearings that are resistant to wear and corrosion can significantly extend the lifespan of the mixer, reducing maintenance costs and improving overall operational efficiency.

Precision Machine Tool Bearings: The Backbone of High-Performance Machinery

In industries where precision is paramount, such as aerospace, automotive, and electronics, the role of precision machine tool bearings cannot be overstated. These bearings are specifically designed to provide high accuracy and minimal friction, enabling machines to operate with extreme precision and speed. Whether it is a CNC machine, a grinding machine, or a lathe, precision machine tool bearings are critical components that ensure smooth motion and exact positioning.

Precision machine tool bearings are made with tight tolerances and often incorporate advanced materials such as ceramic or high-grade steel. These bearings are designed to withstand the rigors of high-speed, high-precision operations, providing exceptional accuracy and minimizing the risk of machine vibration or misalignment.

The selection of precision machine tool bearings is crucial to the performance and reliability of the machinery. Bearings that offer low radial play, high load capacity, and resistance to temperature fluctuations can help maintain consistent machining quality. These bearings play an essential role in minimizing machine downtime and increasing production efficiency, making them a key factor in achieving competitive advantage in industries requiring high levels of precision.

Bearing Machinery: The Technology Behind Bearing Production

The manufacturing of bearings, whether for industrial machinery, automotive applications, or high-precision tools, requires specialized equipment. Bearing machinery includes a wide range of machines used in the production of various types of bearings, from simple ball bearings to complex roller bearings. These machines are designed to ensure that bearings meet stringent quality standards for performance, durability, and reliability.

There are several types of bearing machinery used in the manufacturing process, including turning machines, grinding machines, and assembly machines. These machines are responsible for shaping, finishing, and assembling the various components of the bearings. The process begins with raw materials, such as steel or ceramic, which are shaped and then heat-treated to achieve the required hardness and strength.

Bearing machinery is often equipped with advanced features, such as CNC control and automated assembly, to improve production efficiency and reduce the risk of human error. As the demand for high-quality bearings increases, manufacturers are continuously innovating and developing more advanced bearing machinery to meet the needs of modern industries. These machines not only increase production speed but also enhance the precision of bearings, ensuring that they meet the highest performance standards.

The Importance of Choosing the Right Bearing for Machinery Performance

The choice of bearing has a direct impact on the performance and efficiency of machinery. Whether it is a concrete mixer drum bearing or a precision machine tool bearing, selecting the right bearing ensures that machinery operates smoothly and efficiently, reducing downtime and maintenance costs. Poor-quality bearings can lead to frequent breakdowns, which can be costly in terms of both repairs and lost productivity.

In the case of concrete mixer drum bearings, durability and resistance to harsh environmental conditions are key. These bearings must be able to handle the heavy loads and repetitive motions that are characteristic of concrete mixing. A bearing that fails prematurely can cause the entire mixer to malfunction, disrupting construction schedules and increasing repair costs.

For precision machine tool bearings, the ability to maintain high accuracy is essential. These bearings must be able to support the intricate movements of precision machinery while maintaining exact tolerances. High-performance bearings help achieve smoother finishes, tighter tolerances, and more consistent production quality. Additionally, the right bearings can minimize energy consumption by reducing friction, which is critical for industries looking to improve their sustainability.

Advances in Bearing Technology: Improving Efficiency and Performance

The field of bearing technology has advanced significantly over the years, with innovations designed to improve efficiency, durability, and precision. New materials, such as ceramics and hybrid bearings, offer improved performance in extreme conditions, including higher speeds and temperatures. These innovations are particularly important in sectors like aerospace, automotive, and electronics, where the demands on bearing performance are constantly increasing.

For example, ceramic bearings are becoming increasingly popular in precision machine tools due to their low friction, high hardness, and resistance to wear and corrosion. These bearings can operate at higher speeds and temperatures than traditional steel bearings, making them ideal for high-performance applications. Similarly, hybrid bearings, which combine ceramic and steel components, offer a balance of performance and cost, making them a popular choice in a variety of industries.

In the realm of bearing machinery, advancements in automation and CNC technology have enabled manufacturers to produce bearings with higher precision and efficiency. The use of automated inspection systems has also improved the quality control process, ensuring that each bearing meets the required standards before it is shipped out for use.

Bearing machinery FAQs

What is the role of concrete mixer drum bearings in construction equipment?

Concrete mixer drum bearings play a critical role in enabling the drum to rotate smoothly, facilitating the even mixing of concrete. These bearings support the drum's rotation, which is essential for efficient mixing. The durability and performance of these bearings ensure that the concrete mixer operates reliably in harsh construction environments, minimizing downtime and maintenance costs.

How do precision machine tool bearings differ from standard bearings?

Precision machine tool bearings are designed to operate with high accuracy and low friction, which is essential for precise movements in machinery such as CNC machines and lathes. Unlike standard bearings, which are designed for general applications, precision machine tool bearings are manufactured to exacting tolerances and are made from high-grade materials that can withstand high speeds and loads while maintaining optimal performance.

What are the different types of bearing machinery used in production?

Bearing machinery includes machines such as turning machines, grinding machines, and assembly machines. These machines are responsible for shaping, finishing, and assembling the various components of bearings. Advanced bearing machinery may also include CNC-controlled machines that offer high precision and automation for more efficient production.

Why is it important to choose the right bearing for machinery?

Choosing the right bearing is essential for ensuring optimal performance, longevity, and efficiency of machinery. The correct bearing reduces friction, prevents premature wear, and ensures smooth operation. For example, in a concrete mixer drum bearing, selecting a durable bearing that can withstand heavy loads and harsh environments is critical to maintaining the mixer’s reliability.

What are the benefits of using advanced bearing technology?

Advanced bearing technologies, such as ceramic and hybrid bearings, offer improved performance in extreme conditions, including higher speeds and temperatures. These bearings reduce friction, enhance durability, and extend the life of machinery. Additionally, bearing machinery that incorporates automation and precision technology helps manufacturers improve production efficiency and consistency, leading to lower costs and higher-quality products.

Latest news

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025

-

Everything You Need to Know About the 61906 Bearing | Features, Applications & Vendors

NewsNov.22,2025

Sep . 02, 2024 05:38 Back to list

concrete mixer drum bearing

Understanding the Importance of Concrete Mixer Drum Bearings

Understanding the Importance of Concrete Mixer Drum Bearings

The primary function of a drum bearing in a concrete mixer is to support the rotating drum while facilitating its movement. As the drum turns, it mixes the ingredients — cement, water, and aggregates — to create a homogenous concrete mixture. The bearings reduce friction between the drum and the mixer chassis, enabling smooth rotation, which is crucial for achieving optimum mixing efficiency. Moreover, well-functioning bearings contribute to the longevity of the mixer, ensuring that it can withstand the rigors of continual use.

concrete mixer drum bearing

There are several types of bearings used in concrete mixers, including roller bearings and ball bearings. Roller bearings are typically preferred for heavy-duty applications due to their ability to handle significant loads and provide enhanced durability. Conversely, ball bearings can be more suitable for lighter applications, offering lower friction and faster speeds. The choice of bearing ultimately depends on the specific requirements of the mixer and the conditions under which it operates.

Maintenance of drum bearings is essential for the optimal performance of concrete mixers. Regular inspection is crucial to identify any signs of wear or damage. Producers often recommend checking the bearings for adequate lubrication, as improper lubrication can lead to increased friction and subsequent overheating. Greasing the bearings at regular intervals helps to minimize wear and prolong their lifespan. Furthermore, operators should ensure that debris and concrete buildup around the bearings are cleaned regularly, as obstructions can impede the function and lead to premature failure.

In conclusion, the drum bearing is a fundamental component of a concrete mixer that directly influences its efficiency and longevity. Understanding the types of bearings and their maintenance needs is essential for operators and construction managers alike. By prioritizing the health of these bearings, companies can reduce downtime, increase productivity, and ultimately ensure the success of their concrete mixing operations. Proper attention to this small yet significant element can make a substantial difference in the overall performance of concrete mixers, highlighting the importance of comprehensive maintenance practices in the construction industry.

Latest news

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025

-

Everything You Need to Know About the 61906 Bearing | Features, Applications & Vendors

NewsNov.22,2025