Nov . 11, 2024 03:30 Back to list

Understanding Bearing Taper Sleeves and Their Applications in Machinery Maintenance

Understanding Bearing Taper Sleeves Function, Design, and Applications

Bearing taper sleeves are essential components used in various mechanical assemblies, particularly in applications involving rotating machinery. These specialized sleeves are designed to facilitate the smooth operation of bearings by enhancing their stability, alignment, and overall functionality. In this article, we will delve into the intricacies of bearing taper sleeves, exploring their design, functions, and applications in diverse industrial contexts.

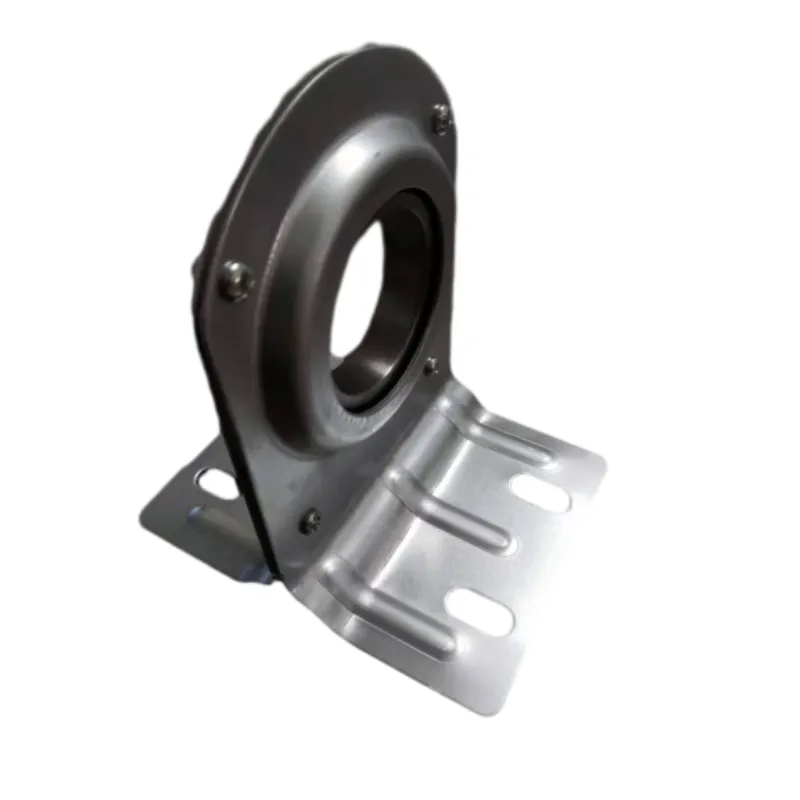

What Are Bearing Taper Sleeves?

Bearing taper sleeves are cylindrical components that have a tapered inner surface. They are typically used to secure rolling element bearings onto a shaft. The taper design allows for a more precise fit, reducing play and enhancing the load-bearing capacity of the assembly. This type of sleeve can be made from various materials, including steel and aluminum, depending on the specific application requirements.

Design and Features

The design of bearing taper sleeves is fundamental to their functionality. The taper allows for a conical shape that aligns with the corresponding taper on the bearing. This design provides a mechanical advantage, allowing for easy mounting and dismounting of the bearing without the need for extensive mechanical intervention.

Some common features of taper sleeves include

1. Material Composition Typically made from high-strength steel, taper sleeves are designed to withstand significant radial and axial loads while maintaining dimensional stability.

2. Surface Finish The inner surface of the taper sleeve is often treated to ensure a smooth finish, reducing friction between the bearing and sleeve, and promoting longer operational life.

3. Precision Engineering The manufacturing process of bearing taper sleeves requires high precision to ensure that the taper angle and diameter are consistent, which is crucial for the effective transmission of loads and forces.

Functions of Bearing Taper Sleeves

Bearing taper sleeves serve several critical functions in machinery. Here are some of the key roles they play

bearing taper sleeve

1. Load Distribution By providing a tight fit between the bearing and shaft, taper sleeves distribute loads evenly, which is crucial for preventing localized stress that could lead to premature wear.

2. Alignment The tapered design helps maintain proper alignment of the bearing on the shaft, reducing the risk of misalignment, which can lead to vibration and operational inefficiencies.

3. Facilitating Assembly The taper design allows for easier assembly and disassembly of the bearing from the shaft. This feature is particularly beneficial during maintenance and repairs, where quick access to bearings is necessary.

4. Enhanced Stability The snug fit provided by taper sleeves helps enhance the overall stability of the assembly, allowing for better performance of the machinery even under varying load conditions.

Applications of Bearing Taper Sleeves

Bearing taper sleeves are widely used across several industries, owing to their versatility and effectiveness. Some notable applications include

1. Automotive Industry In automotive applications, taper sleeves are commonly used in wheel bearings and engine assemblies. Their ability to handle high loads and provide stability makes them ideal for automotive components.

2. Industrial Machinery Taper sleeves are also prevalent in industrial machinery, such as conveyors, turbines, and pumps, where reliable bearing support is essential for efficient operation.

3. Manufacturing Equipment In manufacturing settings, bearing taper sleeves are used in various equipment, including lathes and milling machines, to ensure precise machining operations.

4. Aerospace Engineering The aerospace industry employs bearing taper sleeves in aircraft components, where reliability and performance are critical due to safety concerns.

Conclusion

Bearing taper sleeves may seem like a small component in the grand scheme of machinery design, but they play a pivotal role in ensuring the functionality and longevity of bearings. Their tapered design enhances load distribution, alignment, and stability, making them indispensable in numerous applications, including automotive, industrial machinery, and aerospace. As technology continues to advance, the design and materials used for bearing taper sleeves will likely evolve, further enhancing their performance and adaptability across various industries. Understanding these components' importance and functionality is crucial for engineers and maintenance professionals aiming to optimize machinery performance and reliability.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025