Nov . 19, 2024 14:33 Back to list

Exploring the Features and Benefits of Bearing 32005X in Industrial Applications

The Evolution and Importance of Bearing 32005X A Technical Insight

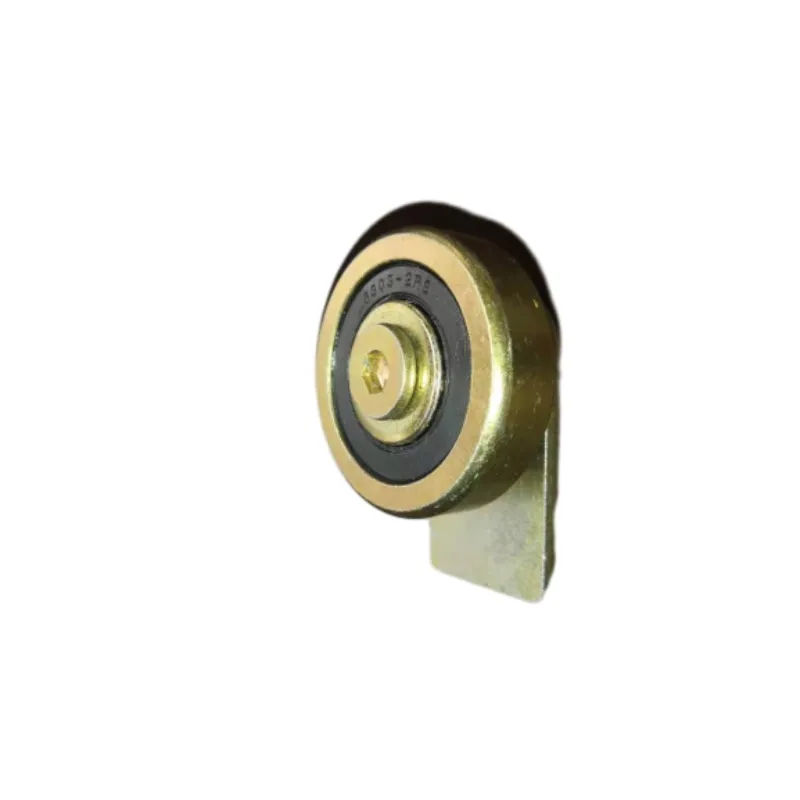

Bearings play a crucial role in the machinery and automotive sectors, facilitating smooth motion and reducing friction. One such important component is the bearing type denominated as 32005X. This article aims to delve into the specifications, applications, and significance of the 32005X bearing in modern industrial practices.

Understanding Bearing 32005X

The designation “32005X” is part of a coding system that denotes a specific type of tapered roller bearing. The first digit “3” indicates that it belongs to a series of metric roller bearings. The “2005” specifies the bearing dimensions, where the first two digits (20) represent the bore diameter in millimeters and the last two digits (05) signify the outer diameter of the bearing, also in millimeters. The “X” often denotes a specific feature or design characteristic that can vary by manufacturer, such as enhanced sealing or a specific type of lubrication.

Tapered roller bearings like the 32005X are designed to support both axial and radial loads, making them versatile components in various applications. The tapered design allows for optimal distribution of load across the bearing, increasing efficiency and extending the service life of the component.

Applications

The utility of the 32005X bearing is extensive. It is commonly found in automotive applications, including wheel hubs and differential assemblies, where it aids in the smooth rotation of tires and gears under varying load conditions. In industrial settings, these bearings are vital in conveyor systems and heavy machinery that require precise movement and alignment.

Moreover, the trend towards more automated systems in manufacturing has increased the demand for high-performance bearings. The 32005X bearing meets these requirements by offering durability and reliability, which are essential for minimizing downtime and maintenance costs in production environments.

bearing 32005x

Material and Design Considerations

The materials used in the production of the 32005X bearing significantly influence its performance. Typically crafted from high-quality steel, these bearings may also undergo heat treatment to enhance their strength and wear resistance. Advanced manufacturing techniques might include surface hardening processes that improve fatigue life, thereby allowing the bearing to withstand the rigors of heavy-duty applications.

From a design perspective, the configuration of the roller and raceway within the bearing is engineered to provide maximum contact area. This design maximizes load-bearing capacity while minimizing stress concentrations, ensuring that the bearing operates efficiently across its operational lifespan.

The Importance of Maintenance

Like any mechanical component, the performance of a 32005X bearing is heavily reliant on proper maintenance. Regular inspection for signs of wear, adequate lubrication, and timely replacement are vital practices that can significantly extend the life of the bearing. Timely interventions can prevent catastrophic failures that could disrupt operations and incur substantial costs.

Additionally, advancements in monitoring technology, such as vibration analysis, allow for predictive maintenance strategies to be employed, ensuring that any potential issues are detected early. Such methods are becoming increasingly prevalent in industries reliant on continuous operation.

Conclusion

The 32005X bearing stands as a testament to the sophistication of engineering in modern machinery. Its ability to support heavy loads while ensuring smooth motion makes it indispensable in various sectors, from automotive to industrial machinery. Understanding its specifications, applications, and the importance of maintenance can help industries leverage the full potential of this vital component. As technology progresses, the continual refinement and evolution of bearing designs will further enhance their performance and reliability, ultimately driving efficiencies across numerous applications. The bearing 32005X, through its endurance and versatility, will undoubtedly remain a pivotal element in mechanical design and functionality.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025