Jun . 14, 2024 12:21 Back to list

Bearing Size Chart Double Row Deep Groove Ball Bearings

A Comprehensive Guide to Double Row Deep Groove Ball Bearings

Introduction

Double row deep groove ball bearings are versatile and widely used in various industries due to their high load capacity, low friction, and excellent performance. This article aims to provide a comprehensive guide to understanding the size chart of double row deep groove ball bearings, helping you select the right bearing for your specific application.

What is a Double Row Deep Groove Ball Bearing?

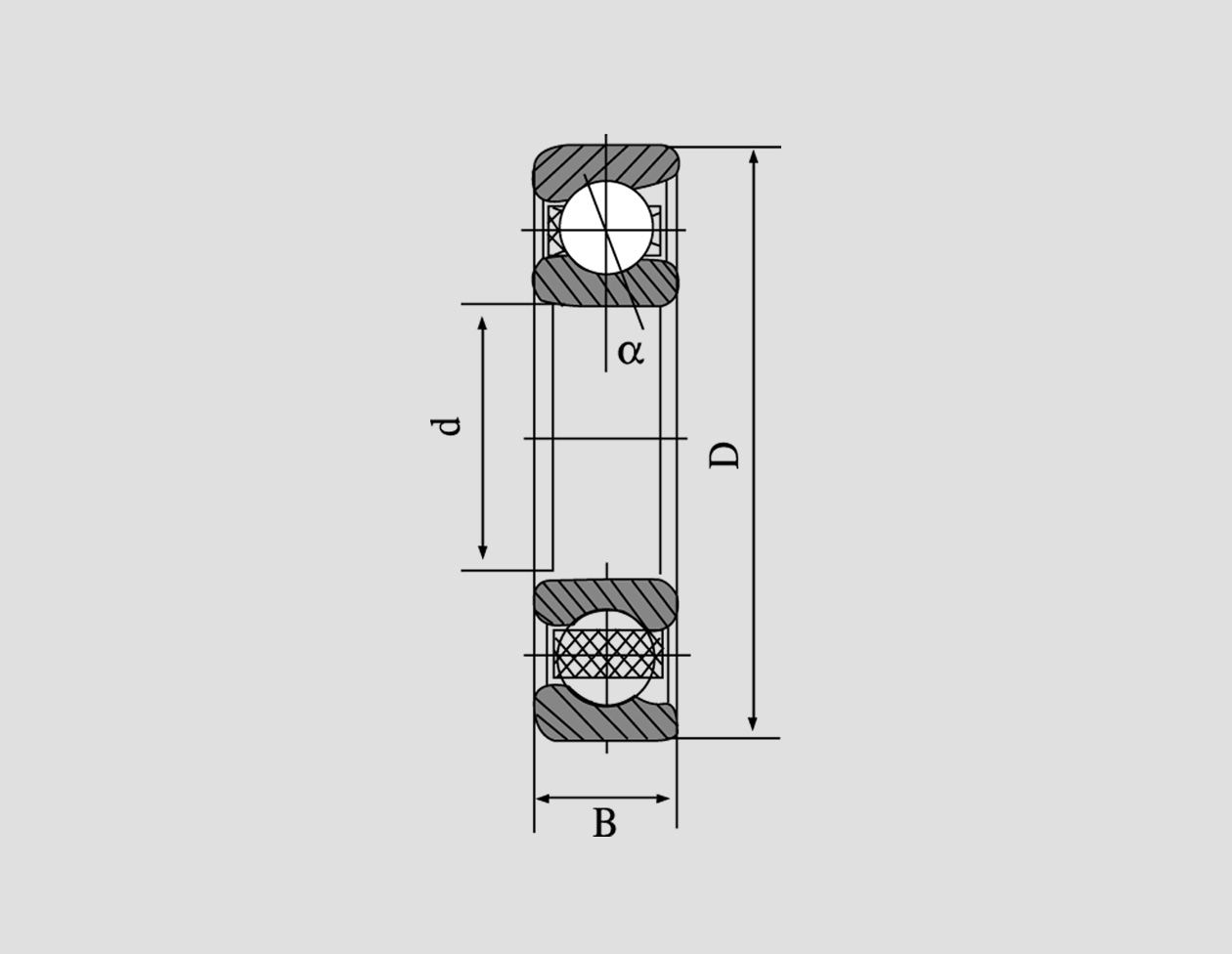

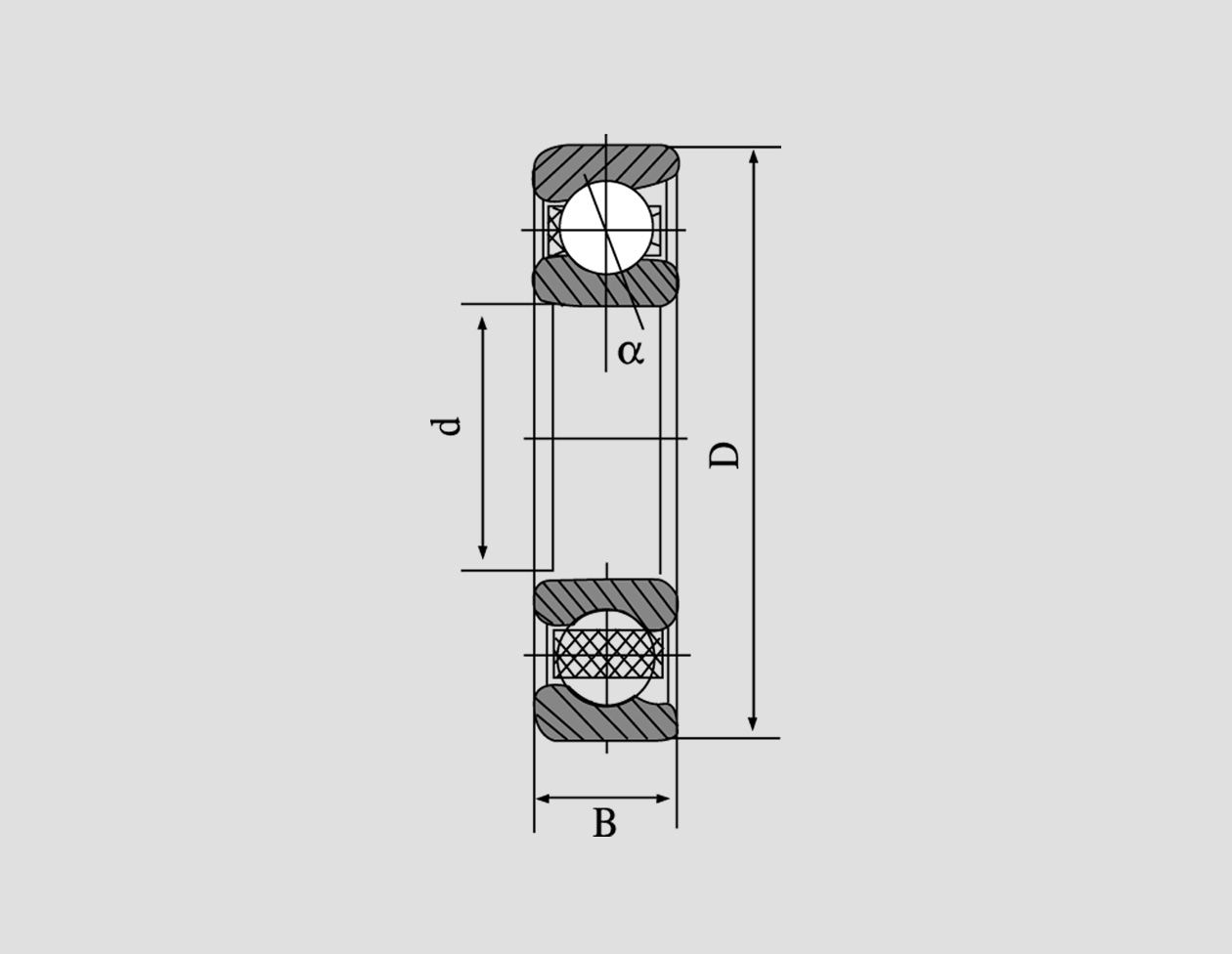

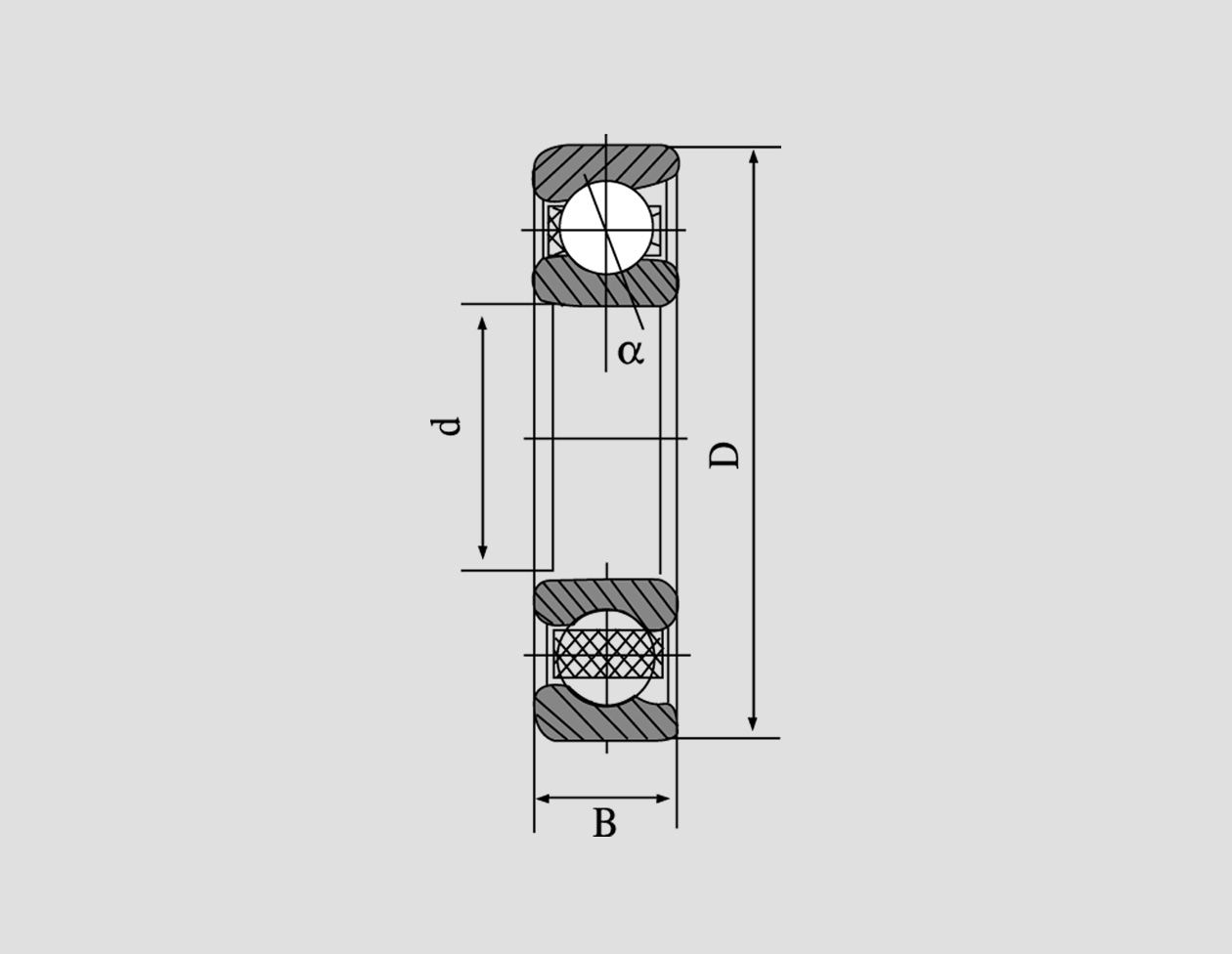

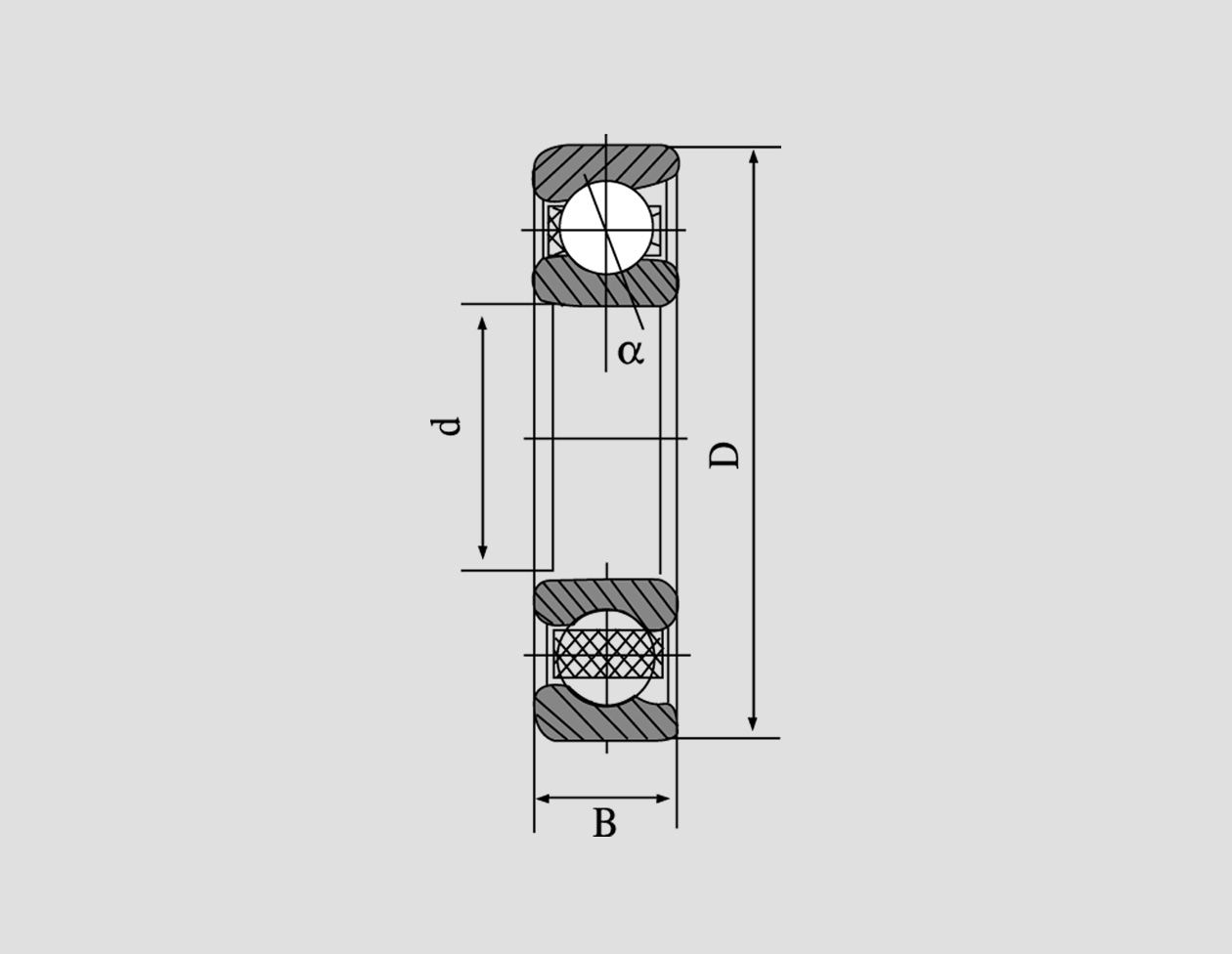

A double row deep groove ball bearing consists of an outer ring, an inner ring, a cage, and a set of steel balls that roll between the rings. The deep groove design provides stability and support, while the balls ensure smooth rotation under heavy loads. These bearings are suitable for applications requiring high speed and precision, such as machine tools, pumps, and gearboxes.

Size Chart of Double Row Deep Groove Ball Bearings

The size chart of double row deep groove ball bearings is typically specified by the internal diameter (ID), external diameter (OD), width (W), and bore diameter (d). The following table shows the standard dimensions for common sizes of double row deep groove ball bearings

| Size | ID (mm) | OD (mm) | Width (mm) | Bore Diameter (mm) |

| --- | --- | --- | --- | --- |

| 6000 Series | 10 | 30 | 9 | 8 |

| 6200 Series | 12 | 32 | 9 | 10 |

| 6300 Series | 15 | 37 | 11 | 13 |

| 6400 Series | 17 | 42 | 14 | 16 |

| 6700 Series | 22 | 52 | 16 | 20 |

?

When selecting the appropriate size of double row deep groove ball bearings, consider the following factors

1. Load capacity The bearing must be able to withstand the applied load without failure. Check the load rating chart provided by the manufacturer to determine the maximum load capacity for your specific bearing size.

2. Speed The bearing's maximum speed depends on its size and design. Larger bearings can handle higher speeds than smaller ones. Consult the manufacturer's data sheet for the maximum speed rating for your desired bearing size.

3

3 3

3

3

3 double row deep groove ball bearing size chart. Space constraints Consider the available space within your machinery to determine the appropriate bearing size. Smaller bearings may be more suitable if space is limited.

4. Shaft diameter The bore diameter of the bearing must match the diameter of the shaft it will be mounted on. Check the manufacturer's specifications to ensure compatibility.

5. Lubrication The bearing's performance is highly dependent on proper lubrication. Choose a bearing with a suitable seal or lubrication system to ensure long-term operation.

Conclusion

Double row deep groove ball bearings are essential components in many industrial applications. By understanding the size chart and considering the relevant factors, you can select the right bearing for your specific needs. Always consult the manufacturer's data sheet and technical specifications for accurate information and guidance.

double row deep groove ball bearing size chart. Space constraints Consider the available space within your machinery to determine the appropriate bearing size. Smaller bearings may be more suitable if space is limited.

4. Shaft diameter The bore diameter of the bearing must match the diameter of the shaft it will be mounted on. Check the manufacturer's specifications to ensure compatibility.

5. Lubrication The bearing's performance is highly dependent on proper lubrication. Choose a bearing with a suitable seal or lubrication system to ensure long-term operation.

Conclusion

Double row deep groove ball bearings are essential components in many industrial applications. By understanding the size chart and considering the relevant factors, you can select the right bearing for your specific needs. Always consult the manufacturer's data sheet and technical specifications for accurate information and guidance.

3

3

3

3 double row deep groove ball bearing size chart. Space constraints Consider the available space within your machinery to determine the appropriate bearing size. Smaller bearings may be more suitable if space is limited.

4. Shaft diameter The bore diameter of the bearing must match the diameter of the shaft it will be mounted on. Check the manufacturer's specifications to ensure compatibility.

5. Lubrication The bearing's performance is highly dependent on proper lubrication. Choose a bearing with a suitable seal or lubrication system to ensure long-term operation.

Conclusion

Double row deep groove ball bearings are essential components in many industrial applications. By understanding the size chart and considering the relevant factors, you can select the right bearing for your specific needs. Always consult the manufacturer's data sheet and technical specifications for accurate information and guidance.

double row deep groove ball bearing size chart. Space constraints Consider the available space within your machinery to determine the appropriate bearing size. Smaller bearings may be more suitable if space is limited.

4. Shaft diameter The bore diameter of the bearing must match the diameter of the shaft it will be mounted on. Check the manufacturer's specifications to ensure compatibility.

5. Lubrication The bearing's performance is highly dependent on proper lubrication. Choose a bearing with a suitable seal or lubrication system to ensure long-term operation.

Conclusion

Double row deep groove ball bearings are essential components in many industrial applications. By understanding the size chart and considering the relevant factors, you can select the right bearing for your specific needs. Always consult the manufacturer's data sheet and technical specifications for accurate information and guidance. Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025