Feb . 14, 2025 06:01 Back to list

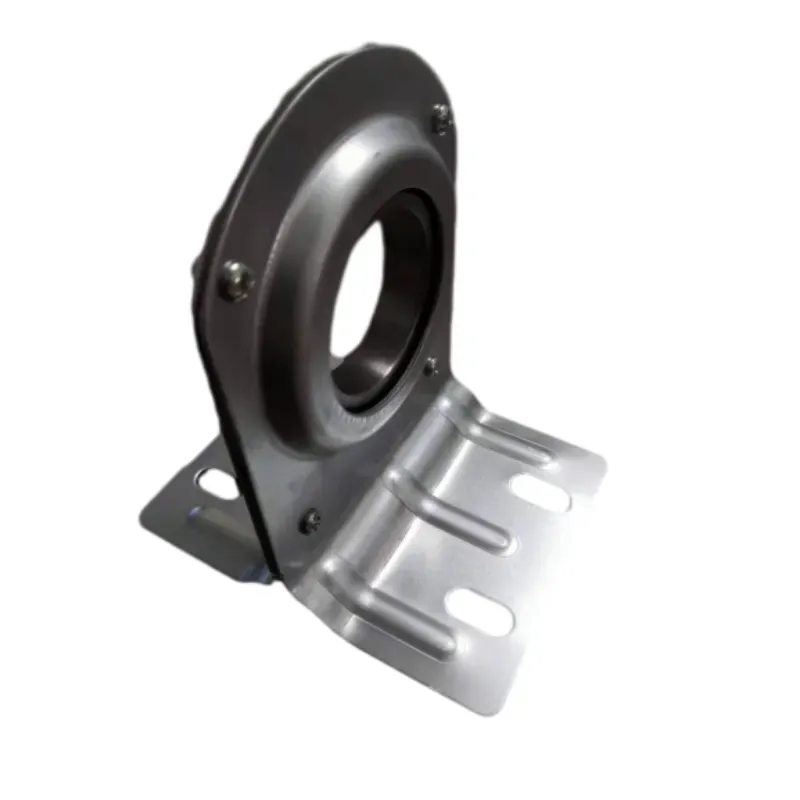

deep groove ball bearing

In the world of mechanical engineering, the ball bearing 609 stands out as a component known for its reliability and essential functionality. This miniature bearing is versatile and highly regarded in various mechanical and electrical applications, making it indispensable in industries ranging from automotive to consumer electronics.

From a user's experience perspective, the 609 ball bearing is known for its smooth operation and ease of maintenance. Its sealed design options offer protection against dust and debris, prolonging the lifespan of the component and reducing maintenance intervals. This feature is particularly valued in applications where downtime can lead to significant operational challenges and cost implications. Moreover, the trustworthiness of the 609 ball bearing extends to its universal acceptability in various machinery. Its compatibility with numerous devices and equipment makes it a go-to solution for engineers seeking replacements or upgrades. The widespread availability also means that spare parts are often easy to source, which is critical for maintaining continuity in manufacturing and production processes. For businesses considering the integration of 609 ball bearings into their products, the return on investment becomes apparent through enhanced product reliability and customer satisfaction. Not only do these bearings enhance the performance of the end product, but they also contribute to a reduction in customer complaints and warranty claims due to their robust nature and dependability. In conclusion, the ball bearing 609 exemplifies a blend of engineering prowess, quality assurance, and practical application. Its enduring presence in the market is a testament to its functional reliability and the confidence it instills among manufacturers and users alike. As industries continue to evolve and demand more from their components, the 609 series remains a cornerstone example of how traditional engineering solutions can adapt to modern challenges while maintaining core attributes of performance and trust.

From a user's experience perspective, the 609 ball bearing is known for its smooth operation and ease of maintenance. Its sealed design options offer protection against dust and debris, prolonging the lifespan of the component and reducing maintenance intervals. This feature is particularly valued in applications where downtime can lead to significant operational challenges and cost implications. Moreover, the trustworthiness of the 609 ball bearing extends to its universal acceptability in various machinery. Its compatibility with numerous devices and equipment makes it a go-to solution for engineers seeking replacements or upgrades. The widespread availability also means that spare parts are often easy to source, which is critical for maintaining continuity in manufacturing and production processes. For businesses considering the integration of 609 ball bearings into their products, the return on investment becomes apparent through enhanced product reliability and customer satisfaction. Not only do these bearings enhance the performance of the end product, but they also contribute to a reduction in customer complaints and warranty claims due to their robust nature and dependability. In conclusion, the ball bearing 609 exemplifies a blend of engineering prowess, quality assurance, and practical application. Its enduring presence in the market is a testament to its functional reliability and the confidence it instills among manufacturers and users alike. As industries continue to evolve and demand more from their components, the 609 series remains a cornerstone example of how traditional engineering solutions can adapt to modern challenges while maintaining core attributes of performance and trust.

Next:

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025