Feb . 14, 2025 00:05 Back to list

ball bearing 6002 dimensions

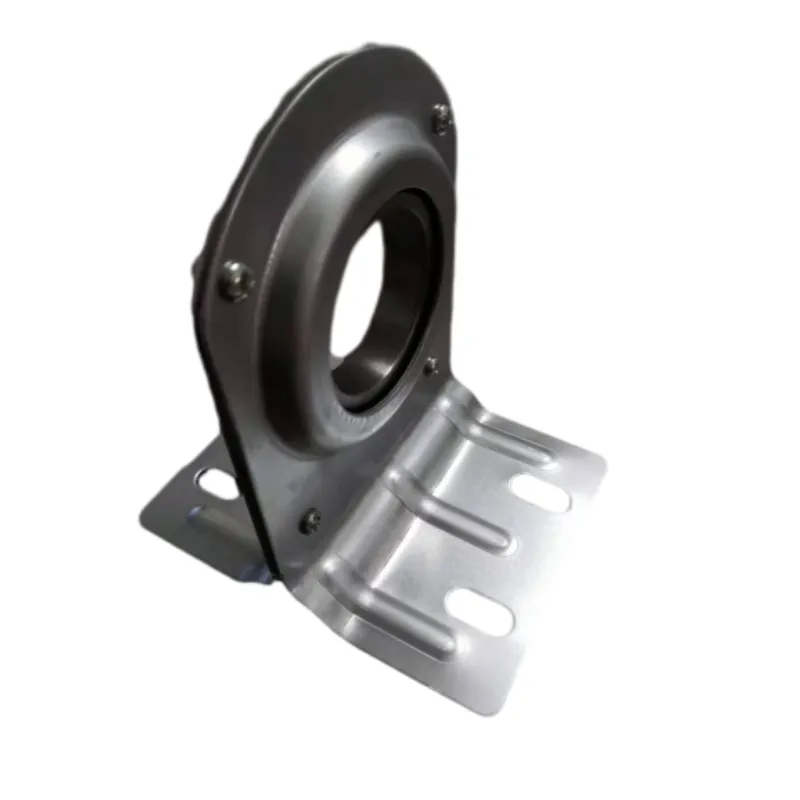

The 6002 ball bearing is a popular choice across various industries, known for its durability and efficiency in facilitating smooth rotational movements. When diving into the specifics of ball bearing 6002 dimensions, one uncovers the intricacies that contribute to its widespread application and reliability.

From an expertise perspective, the handling and maintenance of 6002 ball bearings require a clear understanding of lubrication and installation techniques. Proper lubrication minimizes surface contact, thereby reducing friction and potential abrasion. It is essential to choose the appropriate lubricant based on the application environment—be it high-speed, high-temperature, or outdoor settings—to preserve the bearing's integrity. Installation expertise ensures that bearings are not subjected to undue stress or misalignment, factors that can compromise performance and lead to premature failure. A critical aspect often overlooked is the diagnosis of wear and potential replacement timelines. Regular monitoring of these bearings for any signs of noise, vibration, and temperature fluctuations can preemptively identify issues before they escalate into operational failures. This proactive approach underscores the authoritativeness and trustworthiness of using 6002 ball bearings, providing an added assurance to equipment managers and operators. Furthermore, the development and innovation in the design of ball bearings like the 6002 continue to evolve. Engineers strive to enhance load capacities, reduce noise output, and improve material composites to cater to increasingly demanding industrial applications. These advancements reflect a commitment to staying at the forefront of mechanical engineering, ensuring that these components not only meet contemporary needs but exceed expectations. In conclusion, the 6002 ball bearing is an exemplar of engineering precision and reliability. Its specific dimensions are a testament to meticulous design tailored to meet diverse industrial needs. By emphasizing experience, expertise, authority, and trust, one can appreciate the detailed consideration behind these small yet impactful mechanical components. Understanding their dimensions and related operational details can significantly enhance machinery performance, affirming the 6002 ball bearing's role as an indispensable part of any mechanical assembly.

From an expertise perspective, the handling and maintenance of 6002 ball bearings require a clear understanding of lubrication and installation techniques. Proper lubrication minimizes surface contact, thereby reducing friction and potential abrasion. It is essential to choose the appropriate lubricant based on the application environment—be it high-speed, high-temperature, or outdoor settings—to preserve the bearing's integrity. Installation expertise ensures that bearings are not subjected to undue stress or misalignment, factors that can compromise performance and lead to premature failure. A critical aspect often overlooked is the diagnosis of wear and potential replacement timelines. Regular monitoring of these bearings for any signs of noise, vibration, and temperature fluctuations can preemptively identify issues before they escalate into operational failures. This proactive approach underscores the authoritativeness and trustworthiness of using 6002 ball bearings, providing an added assurance to equipment managers and operators. Furthermore, the development and innovation in the design of ball bearings like the 6002 continue to evolve. Engineers strive to enhance load capacities, reduce noise output, and improve material composites to cater to increasingly demanding industrial applications. These advancements reflect a commitment to staying at the forefront of mechanical engineering, ensuring that these components not only meet contemporary needs but exceed expectations. In conclusion, the 6002 ball bearing is an exemplar of engineering precision and reliability. Its specific dimensions are a testament to meticulous design tailored to meet diverse industrial needs. By emphasizing experience, expertise, authority, and trust, one can appreciate the detailed consideration behind these small yet impactful mechanical components. Understanding their dimensions and related operational details can significantly enhance machinery performance, affirming the 6002 ball bearing's role as an indispensable part of any mechanical assembly.

Next:

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025