Feb . 13, 2025 18:18 Back to list

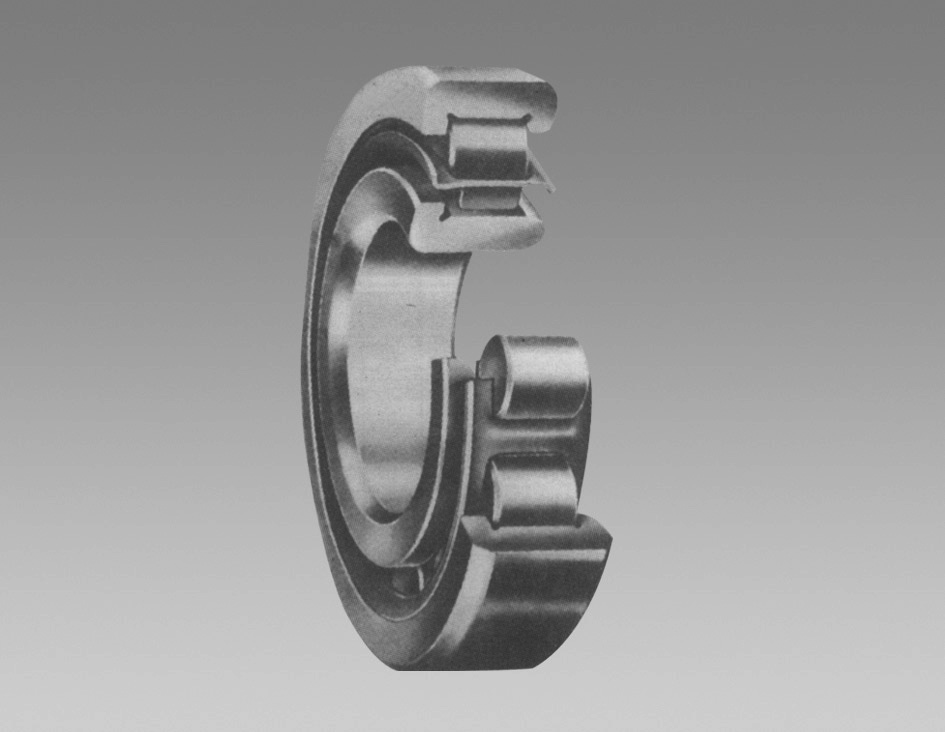

Deep Groove Ball Bearings

Understanding the significance and application of ball bearings, especially the ones that measure 12 * 28 * 8 mm, is pivotal to a plethora of industries. These compact mechanical components are meticulously designed to reduce rotational friction and support radial and axial loads, thus playing a crucial role in the efficient functioning of machinery.

As an authoritative voice in the field, recognizing the signs of wear is crucial. Noise during operation, increased vibration, or excessive play are indicators that a bearing may need replacing. Timely intervention can prevent costly downtimes and extend the life of the machinery. The expertise embedded in these small devices emerges not just from their design but also their application. Engineers and technicians across a multitude of sectors rely on their consistent performance. In sectors as varied as automotive, aerospace, and industrial manufacturing, precision and reliability are key, and these bearings deliver on both fronts. In an increasingly sustainable world, the reuse and recycling of ball bearings have gained attention. Proper disposal and recycling programs underscore the commitment of industries to environmental stewardship, concurrently extending the lifecycle of materials back into the economy. In summary, the 12 * 28 * 8 mm ball bearing encapsulates the essence of engineering efficiency—offering high performance in a compact form. Its success across various applications highlights not just its functional capacity but its role as a cornerstone of modern machinery functionality. This coupling of human ingenuity with mechanical application ensures that industries can rely on these components to drive forward innovation and productivity.

As an authoritative voice in the field, recognizing the signs of wear is crucial. Noise during operation, increased vibration, or excessive play are indicators that a bearing may need replacing. Timely intervention can prevent costly downtimes and extend the life of the machinery. The expertise embedded in these small devices emerges not just from their design but also their application. Engineers and technicians across a multitude of sectors rely on their consistent performance. In sectors as varied as automotive, aerospace, and industrial manufacturing, precision and reliability are key, and these bearings deliver on both fronts. In an increasingly sustainable world, the reuse and recycling of ball bearings have gained attention. Proper disposal and recycling programs underscore the commitment of industries to environmental stewardship, concurrently extending the lifecycle of materials back into the economy. In summary, the 12 * 28 * 8 mm ball bearing encapsulates the essence of engineering efficiency—offering high performance in a compact form. Its success across various applications highlights not just its functional capacity but its role as a cornerstone of modern machinery functionality. This coupling of human ingenuity with mechanical application ensures that industries can rely on these components to drive forward innovation and productivity.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025