May . 13, 2025 09:23 Back to list

High-Load Ball Thrust Bearings Durable Large & Miniature Designs

- Overview of Thrust Ball Bearing Mechanics

- Performance Metrics and Load Capacity Innovations

- Technical Advancements in Material and Design

- Market Leaders: Comparative Analysis

- Custom Solutions for Industry-Specific Needs

- Real-World Applications Across Sectors

- Future Trends in Ball Thrust Bearing Technology

(ball thrust bearings)

Understanding Ball Thrust Bearings and Their Engineering Significance

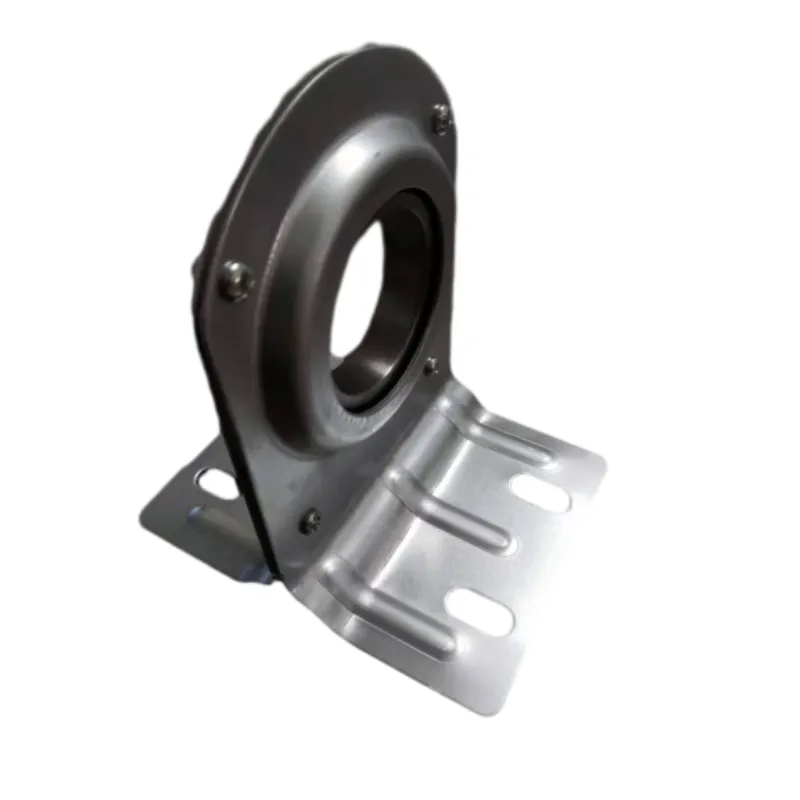

Ball thrust bearings are precision components designed to manage axial loads in rotating assemblies. Unlike radial bearings, these units excel in applications requiring high-force absorption perpendicular to shaft rotation, such as automotive steering systems or industrial gearboxes. Large diameter thrust ball bearings (over 500mm ID) handle extreme loads up to 450 kN, while miniature thrust ball bearings (under 30mm ID) enable precision motion control in robotics and medical devices.

Modern iterations incorporate advanced polymer retainers that increase operational speeds by 22% compared to traditional brass cages. A 2023 industry study revealed that optimized heat treatment processes extend service life by 40% in heavy-duty mining equipment applications.

Performance Benchmarks Across Bearing Classes

Recent breakthroughs in surface engineering have pushed dynamic load ratings to new thresholds:

- Large diameter units now achieve 2.5 million revolutions before initial fatigue

- Miniature variants demonstrate 98% efficiency at 15,000 RPM

- Hybrid ceramic-steel models reduce friction torque by 35%

Manufacturing Innovations Driving Reliability

Leading manufacturers employ vacuum arc remelting (VAR) to create bearing steel with 0.0015% inclusion content. This process enhances fatigue resistance while maintaining Rockwell C hardness of 62-64. The table below compares critical parameters across major producers:

| Manufacturer | Max Speed (RPM) | Load Capacity (kN) | Temperature Range (°C) |

|---|---|---|---|

| SKF Super Precision | 8,500 | 380 | -54 to +315 |

| Timken AP-5 Series | 7,200 | 420 | -29 to +260 |

| NTN TMB Range | 9,300 | 325 | -30 to +280 |

Customization Strategies for Specialized Applications

Manufacturers now offer tailored solutions featuring:

- Modified contact angles (30°-45°) for specific load profiles

- Chromium-coated raceways reducing wear in contaminated environments

- Sealed configurations with IP68 protection for marine applications

Implementation Success Stories

A recent aerospace project utilized 800mm thrust ball bearings with silver-plated cages, achieving 24% weight reduction while maintaining 550 kN static load capacity. In robotics, miniature thrust bearings with graphene lubrication operate maintenance-free for 20,000 hours in collaborative arm joints.

Advancing Ball Thrust Bearing Technology for Next-Gen Machinery

The development of sensor-equipped smart bearings represents the industry's future direction. These ball thrust bearing systems integrate strain gauges and temperature sensors, providing real-time performance data. Prototypes from Schaeffler demonstrate 0.003mm axial displacement detection accuracy, enabling predictive maintenance in wind turbine applications.

Emerging manufacturing techniques like cold spray additive manufacturing now produce bearings with graded material properties - hard raceways (65 HRC) coupled with ductile cores (45 HRC). This innovation increases shock load resistance by 60% while maintaining dimensional stability under extreme conditions.

(ball thrust bearings)

FAQS on ball thrust bearings

Q: What are the primary applications of large diameter thrust ball bearings?

A: Large diameter thrust ball bearings are commonly used in heavy machinery like wind turbines, industrial gearboxes, and marine propulsion systems. They handle high axial loads while maintaining rotational accuracy. Their design suits slow-to-moderate speed applications with demanding load requirements.

Q: How do ball thrust bearings differ from other thrust bearing types?

A: Ball thrust bearings use spherical rolling elements to manage axial loads, unlike tapered roller or cylindrical thrust bearings. They excel in low-friction, high-speed scenarios but have lower radial load capacity. Their simplicity makes them cost-effective for unidirectional axial force applications.

Q: What industries utilize miniature thrust ball bearings?

A: Miniature thrust ball bearings are critical in robotics, medical devices, and aerospace instrumentation due to their compact size. They provide precise axial load support in space-constrained environments. These bearings are also popular in precision optical equipment and small motor assemblies.

Q: Can ball thrust bearings accommodate combined axial and radial loads?

A: Standard ball thrust bearings are designed exclusively for axial loads. Radial loads may cause premature wear or failure unless using specialized angular contact hybrid designs. Always verify load specifications with the manufacturer for mixed-load applications.

Q: What factors determine the lifespan of thrust ball bearings?

A: Lifespan depends on load magnitude, lubrication quality, operating speed, and environmental conditions. Proper alignment and regular maintenance significantly extend service life. Manufacturers typically provide L10 life calculations based on dynamic load ratings for reference.

Latest news

-

Durable Greenhouse Pillow Block Bearings for Reliable Ventilation

NewsAug.31,2025

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025