Nov . 21, 2024 01:36 Back to list

angular contact ball bearing manufacturer

Understanding Angular Contact Ball Bearings A Guide to Manufacturers

Angular contact ball bearings play a crucial role in various industries, including automotive, aerospace, and machinery manufacturing. These bearings are designed to accommodate both radial and axial loads, making them ideal for applications with high speeds and heavy loads. As the demand for specialized components continues to rise, understanding the manufacturing process and attributes of angular contact ball bearings can help in selecting the right supplier for your needs.

What are Angular Contact Ball Bearings?

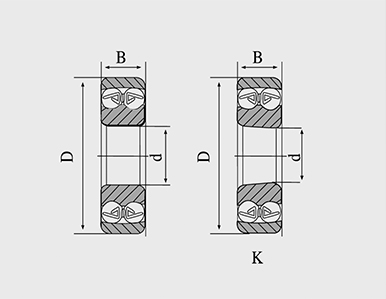

Angular contact ball bearings consist of inner and outer rings, balls, and a cage that holds the balls in place. The key feature of these bearings is that the balls are arranged at an angle, allowing them to handle both radial and axial loads more effectively than standard radial ball bearings. The angle of contact varies based on the bearing design—common angles include 15, 30, and 40 degrees—affecting the bearing's load capacity and speed.

Each bearing is identified by its geometry, material, and design characteristics. For instance, some angular contact ball bearings are single-row designs, while others are double-row. Double-row bearings can handle more significant loads and are often used in applications such as gearboxes and electric motors.

The Importance of Quality Manufacturing

Choosing a reputable angular contact ball bearing manufacturer is vital to ensure the quality and reliability of the bearings. High-quality bearings reduce friction and wear, enhancing the lifespan of machinery and equipment. Manufacturers typically adhere to specific standards, such as ISO 9001, to ensure that their products meet industry regulations.

1. Material Selection The materials used in the manufacturing process significantly influence the performance of angular contact ball bearings. Common materials include high-carbon chromium steel, stainless steel, and ceramic. Each material offers unique properties, such as resistance to corrosion and enhanced wear resistance, which contribute to the overall reliability and efficiency of the bearings.

2. Precision Engineering The manufacturing process involves precision engineering techniques to ensure the correct fit and alignment of the components. Advanced CNC (Computer Numerical Control) machining, heat treatment processes, and surface finishing techniques are employed to produce bearings that perform optimally even under extreme conditions.

3. Testing and Quality Controls Leading manufacturers conduct rigorous testing on their bearing products, including fatigue testing, noise and vibration testing, and performance assessments under various loads. This ensures that only the best products reach the market, which is paramount in industries where reliability and safety are non-negotiable.

angular contact ball bearing manufacturer

Customization Options

Many manufacturers offer customization options to cater to specific application needs. Customization can include varying dimensions, materials, or lubrication methods. This flexibility allows industries to obtain the precise bearings required for unique environments, such as those subjected to high temperatures or corrosive substances.

Key Considerations When Choosing a Manufacturer

When selecting an angular contact ball bearing manufacturer, consider the following factors

1. Experience and Expertise A manufacturer with a long-standing history in the industry is more likely to produce reliable and high-quality products. Look for companies that specialize in bearings and have a track record of successful projects in your area of application.

2. Product Range A diverse product range may indicate a manufacturer’s capability to meet various needs. Suppliers who offer both standard and custom solutions can serve as a one-stop-shop for your bearing requirements.

3. Customer Support Consider the level of customer service offered by the manufacturer. Reliable technical support, warranty options, and after-sales services can significantly enhance your purchasing experience and ensure you get the necessary assistance when required.

4. Certifications Look for manufacturers with recognized certifications, such as ISO or AS9100 for aerospace applications. These certifications demonstrate a commitment to quality standards and continuous improvement.

Conclusion

Angular contact ball bearings are essential components that contribute to the efficiency and longevity of many mechanical systems. By understanding the significance of quality manufacturing and selecting the right manufacturer, businesses can ensure they obtain the best bearings for their applications. Whether you’re involved in automotive, aerospace, or general machinery sectors, investing time in choosing the right angular contact ball bearing supplier will pay off in the long run, enhancing performance and reliability in your operations.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025