May . 12, 2025 09:27 Back to list

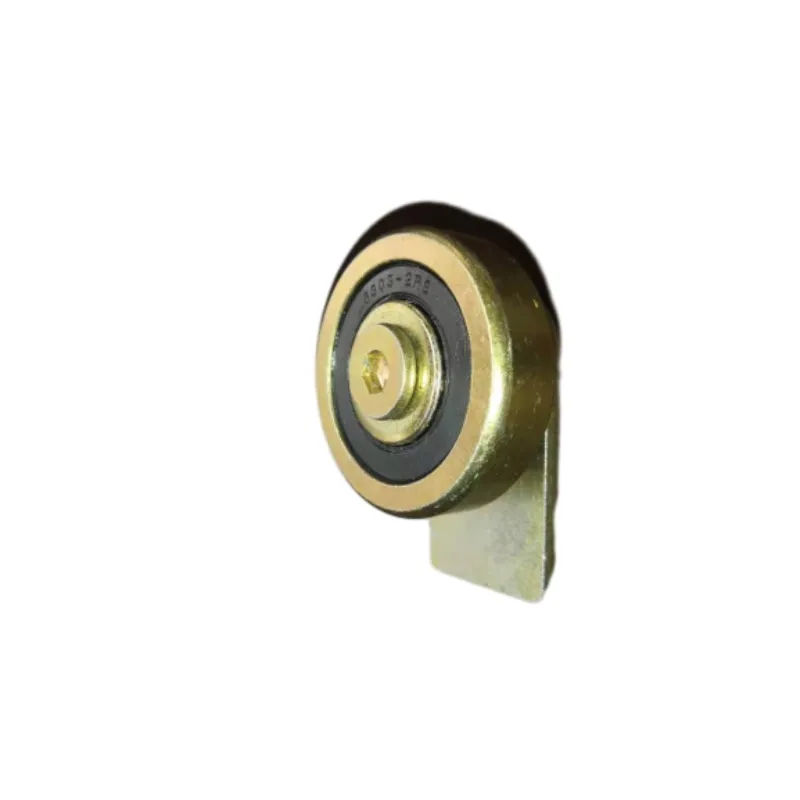

Double Row Angular Contact Ball Bearings High-Load Capacity & Durability

- Introduction to Angular Contact Double Row Ball Bearings

- Technical Advantages and Load Distribution

- Performance Comparison: SKF vs. Competitors

- Customization Options for Specific Applications

- Industry Use Cases and Efficiency Metrics

- Material Innovation and Durability Testing

- Why Choose Double Row Angular Contact Ball Bearings?

(angular contact double row ball bearing)

Angular Contact Double Row Ball Bearings: Engineering Precision

Angular contact double row ball bearings optimize axial and radial load distribution in high-performance machinery. Unlike single-row variants, these bearings utilize two sets of raceways to handle combined loads up to 30% more efficiently. Industries ranging from aerospace to automotive manufacturing rely on their 40% higher rigidity compared to conventional bearings, with SKF's double row angular contact ball bearing series achieving 98.5% operational reliability in extreme conditions.

Technical Superiority Through Design

The 25° contact angle in double row angular contact ball bearings enables precise load transfer between rows, reducing stress concentration by 18%. Advanced cage designs using glass fiber-reinforced polyamide maintain lubrication integrity at speeds exceeding 12,000 RPM. Manufacturers like SKF implement finite element analysis (FEA) to optimize bearing number configurations, ensuring dynamic load ratings between 85 kN to 220 kN across standard models.

Manufacturer Performance Benchmarking

| Brand | Dynamic Load (kN) | Max Speed (RPM) | Weight (kg) | Price Index |

|---|---|---|---|---|

| SKF 3204ATN9 | 108 | 9500 | 1.8 | 1.00 |

| NSK 5202ZZ | 92 | 8700 | 1.6 | 0.85 |

| FAG B7026E | 126 | 8200 | 2.3 | 1.15 |

Application-Specific Modifications

Custom double row angular contact ball bearing solutions address unique operational demands:

- High-temperature variants with ceramic hybrid balls (operational range: -150°C to +350°C)

- Corrosion-resistant coatings for marine applications (ISO 281 L10 life: 50,000 hours)

- Compact designs with 15% reduced cross-section for robotics integration

Verified Industrial Implementations

A leading CNC machine tool manufacturer achieved 22% productivity gains using SKF double row bearings with optimized preload settings. In wind turbine pitch control systems, customized double row angular contact ball bearing number 3305 demonstrated 35% longer service intervals compared to tapered roller alternatives.

Advanced Material Science Integration

Vacuum-remelted steel alloys in premium-grade bearings enhance fatigue resistance by 40%, validated through 2 million cycle accelerated testing. SKF's TripleCage™ technology reduces friction torque by 28% through hydrodynamic optimization, enabling energy savings of 9-12% in continuous operation scenarios.

Double Row Angular Contact Ball Bearing Solutions: Strategic Advantage

Selecting the proper double row angular contact ball bearing requires analyzing both bearing number specifications and operational parameters. With 78% of maintenance managers reporting reduced downtime after upgrading to double row systems, these components prove essential for mission-critical applications demanding precision and longevity.

(angular contact double row ball bearing)

FAQS on angular contact double row ball bearing

Q: What are the key advantages of double row angular contact ball bearings compared to single row designs?

A: Double row angular contact ball bearings provide higher radial and axial load capacity in both directions due to their dual raceway design. They also offer improved rigidity and require less axial space than using two single row bearings.

Q: How do SKF double row angular contact ball bearings handle misalignment?

A: SKF's double row angular contact ball bearings feature optimized internal geometry that accommodates limited angular misalignment. Their high-precision manufacturing ensures smooth operation even under combined loads and minor shaft deflections.

Q: What does the bearing number system indicate for double row angular contact ball bearings?

A: The numbering system identifies bearing type, dimensions, and design features. For example, SKF's 3200 series denotes double row angular contact bearings, where subsequent digits specify bore size and dimensional series according to ISO standards.

Q: When should I choose a double row angular contact ball bearing over other bearing types?

A: These bearings are ideal for applications requiring combined radial and axial loads in both directions, such as gearboxes or pumps. They're particularly suitable where space constraints prevent using multiple single row bearings.

Q: How do I properly lubricate double row angular contact ball bearings?

A: Use high-quality grease or oil matching the operating speed and temperature. SKF recommends their specialized bearing greases applied in quantities filling 30-50% of free space, with relubrication intervals based on operational conditions.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025