Aug . 31, 2024 03:29 Back to list

High-Performance Angular Contact Ball Bearings Manufacturer

Understanding Angular Contact Ball Bearings A Guide to Manufacturers and Their Importance

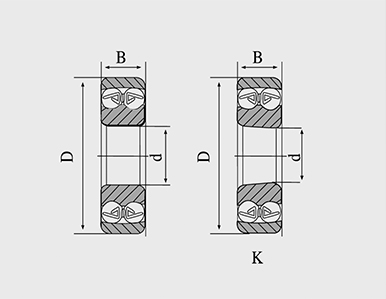

Angular contact ball bearings are a crucial component in various mechanical systems, providing the necessary support and reducing friction between moving parts. Their design allows them to handle both radial and axial loads efficiently, making them ideal for applications requiring high-speed operations and precision. This article delves into the significance of angular contact ball bearings and the manufacturers that supply them.

What are Angular Contact Ball Bearings?

Angular contact ball bearings are characterized by their unique design, which allows the balls to contact the raceway at an angle. This angled contact offers a greater contact area compared to standard radial ball bearings, enabling them to support axial loads in one direction while simultaneously managing radial loads. The angle of contact also improves the bearing's overall stability and allows it to handle higher speeds.

Applications of Angular Contact Ball Bearings

These bearings are widely used in various industries, including automotive, aerospace, and manufacturing. Common applications include

1. Machine Tool Spindles Precision machining requires high-speed rotation and accurate positioning. Angular contact ball bearings provide the necessary support for tool spindles, allowing for enhanced performance and reduced wear.

2. Electric Motors In electric motors, these bearings can handle the dynamic loads that result from rotation while maintaining alignment and reducing vibration.

3. Gearboxes In gearbox assemblies, angular contact ball bearings facilitate smooth operation by managing both axial and radial loads, optimizing performance and extending the lifespan of the gearbox.

angular contact ball bearing manufacturer

Choosing the Right Manufacturer

Selecting a reliable manufacturer for angular contact ball bearings is crucial to ensuring quality and performance. Factors to consider include

1. Reputation and Experience Established manufacturers with a long history in the industry are often more reliable. They have proven their capabilities in producing high-quality bearings that meet various specifications.

2. Product Range A manufacturer that offers a wide range of angular contact ball bearings can cater to different applications and customer needs. This variety allows businesses to find the exact specifications required for their projects.

3. Quality Assurance Look for manufacturers with stringent quality control processes. ISO certification or similar quality standards can help ensure that the bearings produced meet international quality benchmarks.

4. Technical Support A good manufacturer should provide excellent customer service and technical support. They should be able to assist customers with product selection, installation, and maintenance to ensure optimal performance.

Conclusion

Angular contact ball bearings play an indispensable role in modern machinery, offering improved efficiency, durability, and performance. As industries continue to evolve, the demand for high-quality bearings will remain significant. By selecting reputable manufacturers who prioritize quality and customer service, businesses can ensure their operations run smoothly and efficiently. Whether you are in the automotive sector, aerospace, or any other industry that relies on precision machinery, understanding the importance of angular contact ball bearings and their manufacturers is essential for success. Investing in these components will ultimately contribute to the longevity and reliability of your machinery.

Latest news

-

Industrial Machine Bearings: the core hub of mechanical operation

NewsAug.06,2025

-

Deep Groove Ball Bearing: A Dynamic "Elf" Operating Mechanically

NewsAug.06,2025

-

Compact craftsmanship: the way to optimize the space of Concrete Mixer Bearings

NewsAug.06,2025

-

Combine Harvester Bearings: The 'Steel Backbone' of Modern Agriculture

NewsAug.06,2025

-

Bearing Machinery: a flexible support hub for mechanical operation

NewsAug.06,2025

-

Agricultural Equipment Bearings: A Power Hub for Intensive Cultivation under Radial Space Constraints

NewsAug.06,2025