Dec . 05, 2024 18:59 Back to list

30mm Bore Deep Groove Ball Bearing Series for Robust Industrial Applications

Understanding the 2002 Series Single-Row Deep Groove Ball Bearing with a 30mm Bore

When it comes to precision engineering and mechanical applications, bearings play a crucial role. Among the various types of bearings available, the single-row deep groove ball bearing stands out for its versatility and efficiency. One specific type that has garnered attention is the 2002 series single-row deep groove ball bearing with a 30mm bore. In this article, we will explore its features, functions, applications, and maintenance considerations.

What is a Deep Groove Ball Bearing?

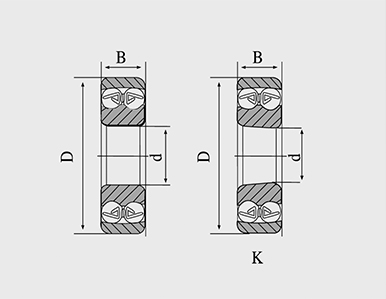

Deep groove ball bearings are one of the most common types of rolling bearings. They consist of an inner ring, an outer ring, a group of balls, and a cage that holds the balls in position. The raceways on both the inner and outer rings are deep and curved, allowing the bearing to support radial and axial loads in both directions. This design results in minimal friction, which enhances the bearing's efficiency.

Features of the 2002 Series with a 30mm Bore

The 2002 series, specifically featuring a 30mm bore, is characterized by its robustness and high load capacity. Key features include

1. Standardized Inner and Outer Diameters The 30mm bore means that the inner ring has a diameter of 30mm, making it compatible with a wide range of shafts, ensuring ease of integration into mechanical systems.

2. High-Speed Capability Deep groove ball bearings are designed to handle high rotational speeds. The specific engineering of the 2002 series allows it to maintain performance even under challenging conditions.

3. Precision Manufacturing The components of this bearing are manufactured with high precision, which means they can achieve tight tolerances. This precision is crucial for applications demanding accuracy.

4. Durable Materials Often made from high-quality steel, these bearings provide resistance to wear and corrosion, extending their operational lifespan.

5. Sealing Options Many 2002 series deep groove ball bearings come with the option of sealed or shielded designs, which help prevent contamination from dust and lubricants while retaining grease.

Applications

The 2002 series single-row deep groove ball bearing finds applications in a variety of fields, including

an 02-series single-row deep-groove ball bearing with a 30mm bore

- Automotive Industry They are widely used in wheel hubs, electric motors, and gearbox assemblies, enhancing the efficiency and longevity of automotive components.

- Electronics These bearings are used in small motors and equipment, such as fans and blowers, where space is limited but reliability is crucial.

- Industrial Machinery In factories and assembly lines, these bearings are essential for the smooth operation of conveyors, pumps, and textile machinery.

- Household Appliances They play a vital role in items such as washing machines, refrigerators, and HVAC systems, contributing to their efficiency and functionality.

Maintenance Considerations

To ensure the longevity and performance of the 2002 series deep groove ball bearing, regular maintenance is essential

1. Lubrication Proper lubrication reduces friction between moving parts. Depending on the application, bearings can be lubricated with oil or grease. It’s important to follow manufacturer guidelines for lubrication intervals.

2. Condition Monitoring Regular inspection for signs of wear, such as increased noise or vibration, can prevent failure. Tools such as vibration analysis and thermography can help in monitoring the condition of the bearings.

3. Environment Control Keeping the bearings in a clean and controlled environment can prevent contamination that may lead to premature failure.

4. Proper Installation Ensuring that the bearing is installed correctly on the shaft and in the housing is critical. Misalignment can lead to uneven loading and increased wear.

Conclusion

The 2002 series single-row deep groove ball bearing with a 30mm bore represents a reliable and efficient choice for various engineering applications. Its robust design, combined with high-speed capabilities and durability, makes it an invaluable component in many machines and devices. By understanding its features, applications, and maintenance needs, engineers and technicians can make informed decisions that enhance machinery performance and reliability. Whether in automotive, industrial, or consumer applications, this bearing type continues to support innovations and efficiencies in technology.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025