Feb . 11, 2025 13:42 Back to list

6310 bearing size

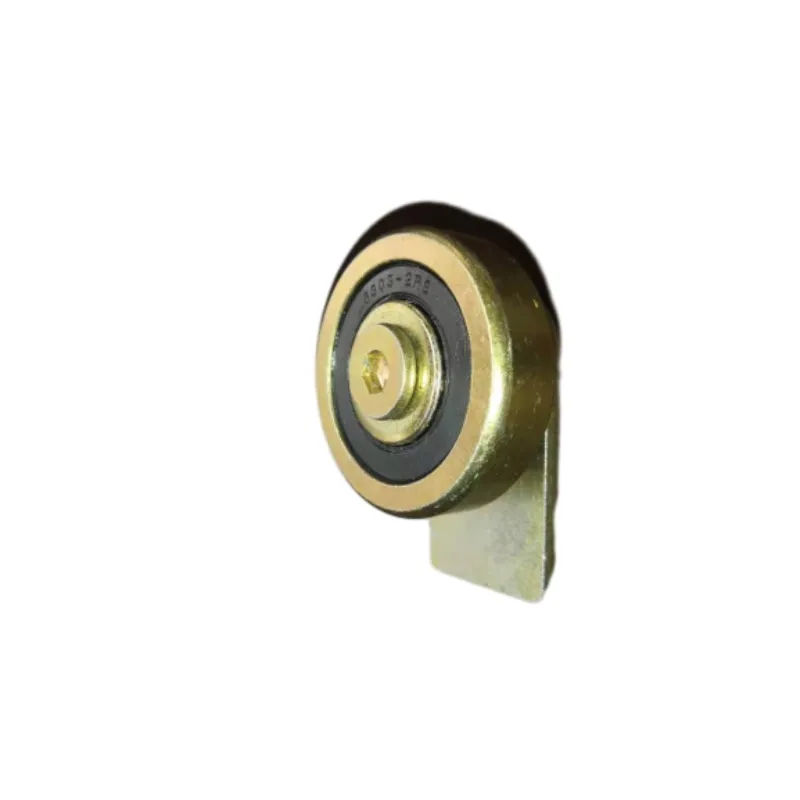

When discussing the realm of bearings, particularly the 6310 bearing, understanding its size and application is vital for industries that rely on these components for machinery and equipment efficiency. The 6310 bearing is a type of deep groove ball bearing, a component known for its versatility, robustness, and ability to support high radial loads. This versatility makes it popular across various industries including automotive, aerospace, and manufacturing.

The reputation of the 6310 bearing is backed by authoritative studies and expert recommendations from mechanical engineers and industry leaders. These experts underscore the importance of the bearing's role in both simple and complex machinery, often recommending it for applications that demand high reliability and efficiency. They emphasize the significance of choosing the right bearing based on exact measurements and load requirements, advocating for its widespread use across sectors due to its proven track record of performance and durability. Trust in the 6310 bearing stems from its consistent performance and the trustworthiness of manufacturers who adhere to stringent quality standards. Certifications and rigorous testing processes are part and parcel of manufacturing these components, ensuring that they meet international benchmarks for safety and performance. Industries with zero tolerance for failure, such as aerospace and defense, regularly utilize the 6310 bearing, highlighting its dependability. Professionals considering the 6310 bearing should also be aware of the lubrication requirements and maintenance practices necessary to optimize its lifespan. Adequate lubrication reduces friction and heat generation, essential factors in preventing premature wear. Regular inspections and maintenance schedules can preempt potential failures, sustaining the operational efficiency of machinery and minimizing costly downtimes. In summary, the 6310 bearing is a highly reliable component known for its precise dimensions and capability to handle demanding applications. With a strong foundation in engineering design and an endorsement from industry experts, it remains a preferred choice in many sectors. Understanding its specifications and selecting the right supplier ensures that businesses can leverage the full benefits of this robust component, reinforcing their machinery's performance and longevity.

The reputation of the 6310 bearing is backed by authoritative studies and expert recommendations from mechanical engineers and industry leaders. These experts underscore the importance of the bearing's role in both simple and complex machinery, often recommending it for applications that demand high reliability and efficiency. They emphasize the significance of choosing the right bearing based on exact measurements and load requirements, advocating for its widespread use across sectors due to its proven track record of performance and durability. Trust in the 6310 bearing stems from its consistent performance and the trustworthiness of manufacturers who adhere to stringent quality standards. Certifications and rigorous testing processes are part and parcel of manufacturing these components, ensuring that they meet international benchmarks for safety and performance. Industries with zero tolerance for failure, such as aerospace and defense, regularly utilize the 6310 bearing, highlighting its dependability. Professionals considering the 6310 bearing should also be aware of the lubrication requirements and maintenance practices necessary to optimize its lifespan. Adequate lubrication reduces friction and heat generation, essential factors in preventing premature wear. Regular inspections and maintenance schedules can preempt potential failures, sustaining the operational efficiency of machinery and minimizing costly downtimes. In summary, the 6310 bearing is a highly reliable component known for its precise dimensions and capability to handle demanding applications. With a strong foundation in engineering design and an endorsement from industry experts, it remains a preferred choice in many sectors. Understanding its specifications and selecting the right supplier ensures that businesses can leverage the full benefits of this robust component, reinforcing their machinery's performance and longevity.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025