Dec . 31, 2024 15:03 Back to list

Detailed Specifications and Dimensions of 6309 Bearing for Industrial Applications

Understanding 6309 Bearings Dimensions and Applications

Bearings are crucial components in various machinery and equipment, facilitating smooth movement between different parts while minimizing friction. Among the wide range of bearings available, the 6309 bearing has garnered attention due to its versatility, reliability, and specific dimensions that make it suitable for numerous applications. In this article, we will explore the dimensions, characteristics, and uses of the 6309 bearing, providing an in-depth understanding of its role in engineering.

Dimensions of the 6309 Bearing

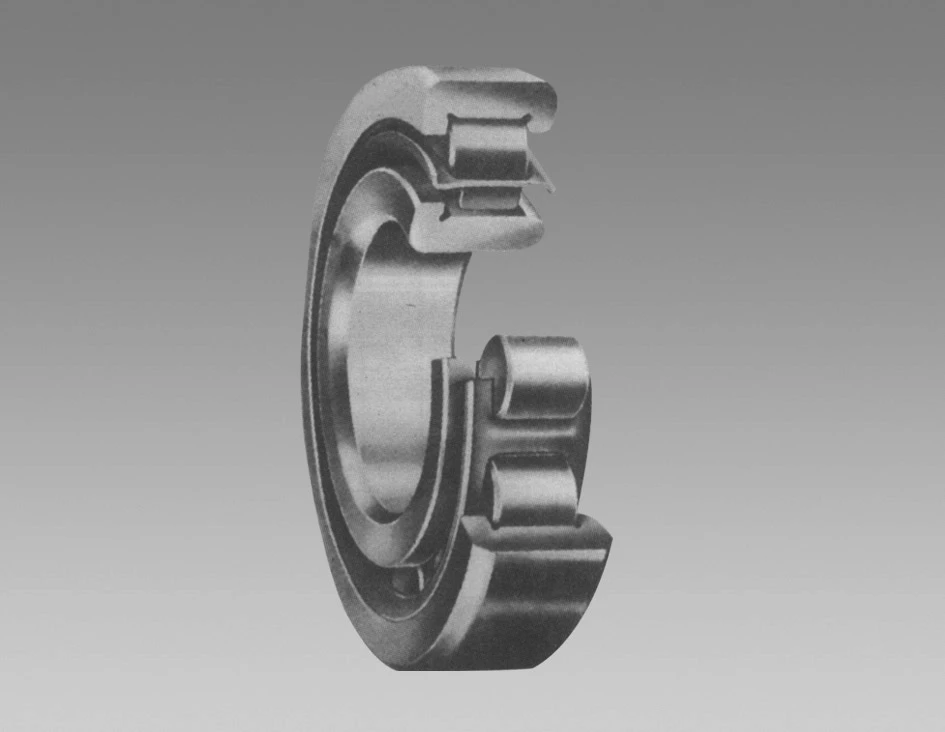

The 6309 bearing is a single-row deep groove ball bearing that is widely used in different mechanical systems. One of the key features of the 6309 bearing is its dimensions. The standard specifications for a 6309 bearing are as follows

- Inner Diameter (ID) 45 mm - Outer Diameter (OD) 100 mm - Width (B) 25 mm

These dimensions give the 6309 bearing the ability to handle radial and axial loads in both directions, making it an excellent choice for applications with combined loading conditions. The deep groove design allows for high speeds and provides effective sealing against contaminants, ensuring durability and extended service life.

Material and Design

The materials used in the construction of the 6309 bearing are pivotal to its performance. Typically, these bearings are made from high-carbon chromium steel, which provides excellent hardness and wear resistance. Additionally, some variations of the 6309 bearing may utilize stainless steel to enhance corrosion resistance, particularly in environments exposed to moisture or chemical exposure.

The design of the bearing includes a cage that keeps the rolling elements spaced evenly, allowing for smooth operation and reducing vibration. This design is essential in applications requiring precision and minimal noise, such as in electric motors and automotive components.

Applications of the 6309 Bearing

6309 bearing dimensions

The versatility of the 6309 bearing lends itself to various industries and applications. Some common uses include

1. Electric Motors The 6309 bearing is frequently employed in electric motors, where its ability to handle high speeds and loads is critical for efficient operation.

2. Automotive Applications This bearing is often found in wheel hubs, gearboxes, and alternators, playing a vital role in ensuring smooth performance and reliability in automotive systems.

3. Industrial Machinery Many types of machinery, including pumps, conveyors, and industrial fans, utilize 6309 bearings due to their robustness and capacity to operate under heavy loads.

4. Home Appliances From washing machines to refrigerators, the 6309 bearing’s efficiency and low maintenance make it a common choice in various household appliances.

Maintenance and Longevity

To maximize the lifespan of a 6309 bearing, proper maintenance is essential. Regular lubrication helps reduce friction and wear, ensuring smooth operation. It's also essential to check for signs of wear or damage regularly. If any abnormal noises or vibrations are detected, it may indicate that a replacement is necessary to prevent further damage to the machinery.

Conclusion

In conclusion, the 6309 bearing is a reliable and versatile component widely used across numerous industries due to its specific dimensions and design features. Its ability to support significant loads, operate at high speeds, and withstand various environmental conditions makes it an invaluable part of many machines. By understanding its dimensions and applications, engineers and technicians can make informed decisions when selecting bearings for their specific needs. Whether in automotive applications, industrial machinery, or household appliances, the 6309 bearing continues to play a pivotal role in modern engineering. Proper maintenance of this bearing will ensure longevity and efficiency, contributing to the overall performance of the equipment it supports.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025