Sep . 04, 2024 05:47 Back to list

6309 bearing dimensions

The 6309 bearing is a popular type of deep groove ball bearing used in various applications due to its versatility, reliability, and ease of maintenance. Understanding its dimensions and specifications is crucial for engineers and technicians involved in machinery and automotive maintenance, as well as in the design of various mechanical systems.

Dimensions of the 6309 Bearing

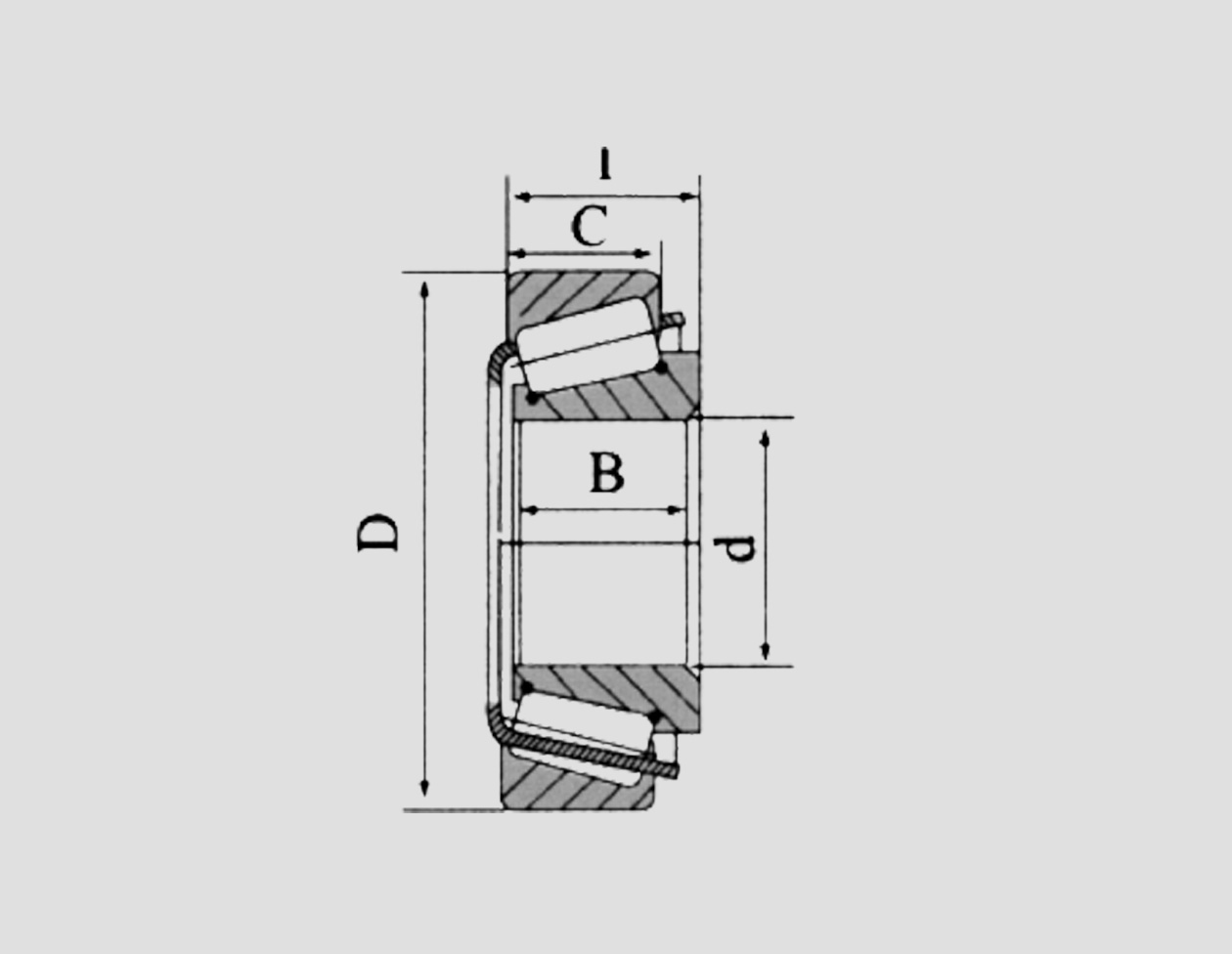

The 6309 bearing is characterized by specific dimensions that make it suitable for a wide range of applications. Its dimensions are as follows

- Inner Diameter (ID) 45 mm - Outer Diameter (OD) 100 mm - Width (W) 25 mm

These dimensions allow the 6309 bearing to accommodate moderate radial loads and axial loads in both directions, making it an ideal choice for electric motors, agricultural equipment, and various industrial machinery.

Material and Design

The 6309 bearing is typically made from high carbon chromium steel, providing excellent hardness and wear resistance. This material choice ensures a long service life and operational stability. Additionally, the precision design of the bearing minimizes friction, allowing for smooth rotation and reduced energy consumption.

The deep groove design enables the 6309 bearing to handle both radial and axial loads effectively, making it a versatile option for a multitude of applications. Furthermore, these bearings can be sealed or shielded, providing additional protection against contaminants such as dust and moisture, which can significantly impact performance and longevity.

6309 bearing dimensions

Applications

Due to its robust design and favorable dimensions, the 6309 bearing is widely used across various sectors. Some common applications include

- Electric Motors They are frequently used in electric motors for their ability to handle high speeds and heavy loads. - Automotive Industry In vehicles, 6309 bearings are commonly employed in wheel hubs and transmissions, where reliable performance is critical. - Manufacturing Equipment Many machines in manufacturing and processing industries utilize these bearings due to their reliability and ease of replacement.

Maintenance and Replacement

Maintaining the 6309 bearing is straightforward, as it typically requires regular lubrication to ensure its performance is not compromised over time. Periodic inspection for wear and contamination can prevent premature failure, which is essential in maintaining the efficiency of the machinery it supports.

When replacement becomes necessary, it is crucial to choose a bearing that meets the same specifications to ensure compatibility and performance. The 6309 bearing is readily available in the market from various manufacturers, providing a good balance between cost and quality.

Conclusion

In summary, the 6309 bearing is an essential component in many mechanical applications, celebrated for its robust dimensions and versatile performance. Knowledge of its specifications and applications can help users make informed decisions and ensure the longevity of their equipment. Whether in automotive, industrial, or electric applications, the 6309 bearing stands out for its reliability and effectiveness, proving to be a staple in the world of bearings.

Latest news

-

Industrial Machine Bearings: the core hub of mechanical operation

NewsAug.06,2025

-

Deep Groove Ball Bearing: A Dynamic "Elf" Operating Mechanically

NewsAug.06,2025

-

Compact craftsmanship: the way to optimize the space of Concrete Mixer Bearings

NewsAug.06,2025

-

Combine Harvester Bearings: The 'Steel Backbone' of Modern Agriculture

NewsAug.06,2025

-

Bearing Machinery: a flexible support hub for mechanical operation

NewsAug.06,2025

-

Agricultural Equipment Bearings: A Power Hub for Intensive Cultivation under Radial Space Constraints

NewsAug.06,2025