Jan . 20, 2025 00:19 Back to list

6307 bearing dimensions

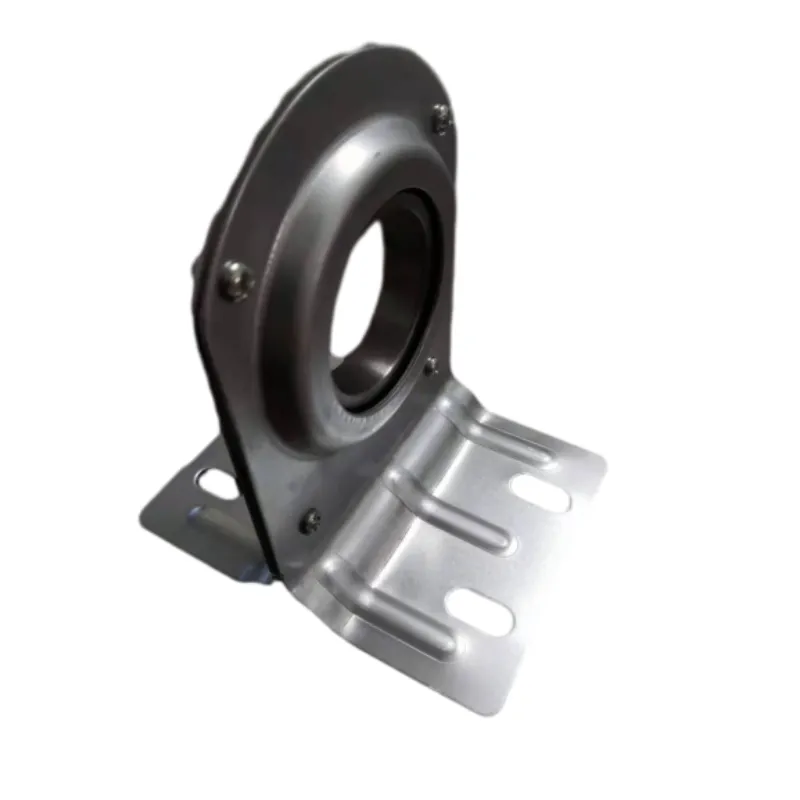

The 6307 bearing is an integral component widely used in various industries, owing to its versatility and reliability. Understanding the dimensions and specifications of this particular bearing is crucial for anyone involved in manufacturing, mechanical engineering, or maintenance. This article delves into the specifics of the 6307 bearing dimensions, offering a comprehensive guide based on industry expertise and real-world experience to ensure optimal performance and longevity.

Lubrication is paramount to bearing health, affecting both speed and load capabilities. The lubrication choice depends heavily on the operational environment and the bearing's intended application. In most scenarios, high-quality grease is recommended for its stability and ability to maintain viscosity under different operational temperatures. However, applications subject to extreme conditions might necessitate special lubricants, requiring expert consultation to prevent premature wear and ensure efficient operation. Installation and maintenance are also crucial for optimizing the lifespan of 6307 bearings. During installation, ensuring that the bearing remains free of dust and moisture is important. Improper handling during the installation process often leads to misalignment, reducing efficiency and increasing the likelihood of bearing failure. Regular maintenance checks for signs of wear or misalignment can prevent unexpected failures and extend the bearing's service life. This preventive measure is an area where experience truly shows, as seasoned technicians can often identify potential issues before they escalate. Finally, sourcing from reputable manufacturers reinforces trustworthiness and assures quality. Leading manufacturers provide comprehensive documentation that includes all necessary technical specifications and support assistance when required. This support is invaluable for those requiring tailored guidance and technical insights into specific applications. In conclusion, the 6307 bearing stands as a testament to engineering proficiency that requires careful consideration of its dimensions, material, speed rating, lubrication, and installation. Professionals who comprehend these elements can ensure these bearings function effectively, thereby contributing to prolonged equipment reliability and operational efficiency.

Lubrication is paramount to bearing health, affecting both speed and load capabilities. The lubrication choice depends heavily on the operational environment and the bearing's intended application. In most scenarios, high-quality grease is recommended for its stability and ability to maintain viscosity under different operational temperatures. However, applications subject to extreme conditions might necessitate special lubricants, requiring expert consultation to prevent premature wear and ensure efficient operation. Installation and maintenance are also crucial for optimizing the lifespan of 6307 bearings. During installation, ensuring that the bearing remains free of dust and moisture is important. Improper handling during the installation process often leads to misalignment, reducing efficiency and increasing the likelihood of bearing failure. Regular maintenance checks for signs of wear or misalignment can prevent unexpected failures and extend the bearing's service life. This preventive measure is an area where experience truly shows, as seasoned technicians can often identify potential issues before they escalate. Finally, sourcing from reputable manufacturers reinforces trustworthiness and assures quality. Leading manufacturers provide comprehensive documentation that includes all necessary technical specifications and support assistance when required. This support is invaluable for those requiring tailored guidance and technical insights into specific applications. In conclusion, the 6307 bearing stands as a testament to engineering proficiency that requires careful consideration of its dimensions, material, speed rating, lubrication, and installation. Professionals who comprehend these elements can ensure these bearings function effectively, thereby contributing to prolonged equipment reliability and operational efficiency.

Next:

Latest news

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025