Dec . 11, 2024 10:45 Back to list

Specifications and Features of 6212 Bearing for Optimal Performance and Application

Understanding the 6212 Bearing Specifications

Bearings are essential components in various machines and applications, providing support and reducing friction between moving parts. Among the myriad types of bearings, the 6212 bearing stands out for its versatility and reliability. This article delves into the specifications, applications, and significance of the 6212 bearing in engineering and machinery.

What is a 6212 Bearing?

The 6212 bearing is classified as a deep groove ball bearing. The numeric designation ‘6212’ indicates its series and size. The first two digits, '62', denote the series of deep groove ball bearings, and '12' indicates the bore diameter in millimeters, which is 60 mm for this particular bearing. The 6212 bearing typically has an outer diameter of 110 mm and a width of 22 mm. These dimensions make it suitable for a broad range of applications where demands for load-bearing capacity, durability, and operational efficiency are crucial.

Key Specifications

1. Dimensions - Inner Diameter 60 mm - Outer Diameter 110 mm - Width 22 mm

2. Load Ratings - Dynamic Load Rating (C) Approximately 54 kN - Static Load Rating (C0) Approximately 32 kN

3. Speed Ratings - The limit speed for the 6212 bearing varies depending on the lubricant and application. Generally, it can operate effectively at speeds up to 6,000 RPM.

4. Materials - The inner and outer races are typically constructed from high carbon chrome steel, providing excellent resistance to wear and deformation under load. The balls inside the bearing are also made from similar materials to ensure longevity and performance.

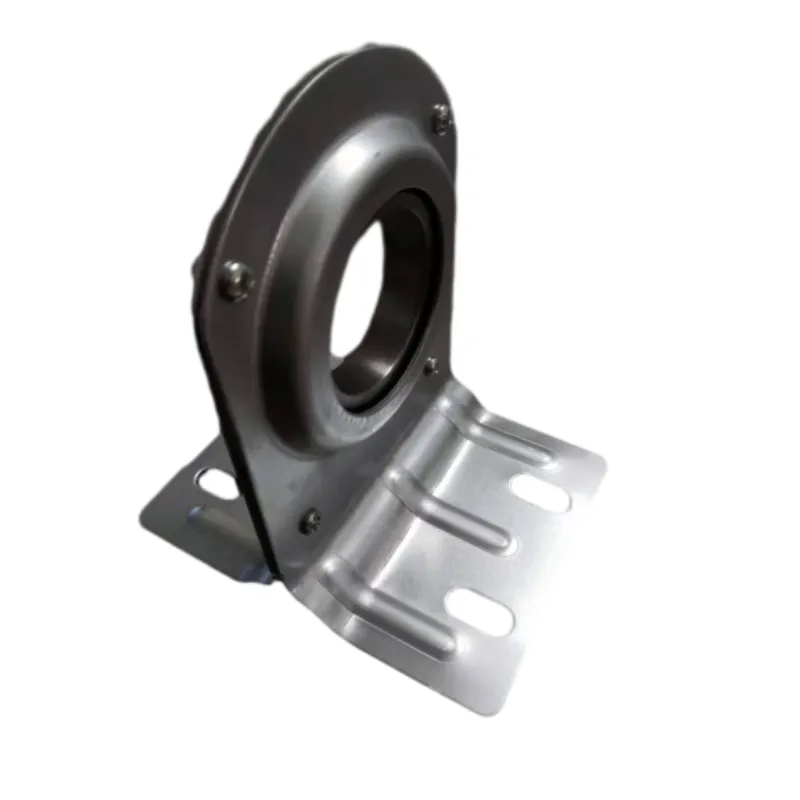

6212 bearing specifications

5. Seal Types - The 6212 bearing can come with open designs or sealed (either with rubber seals - 2RS or with metal shields - ZZ) to protect the internal components from dust and moisture. Sealed bearings offer reduced maintenance and increased durability in harsh environments.

Applications

The versatility of the 6212 bearing allows it to be used in a wide variety of applications, including

- Automotive Industry Used in components such as wheels, gearboxes, and electric motors. - Industrial Machinery Essential in conveyor systems, pumps, and compressors. - Electric Motors Common in low-to-medium power electric motors due to its high-speed capabilities and load resistance. - Home Appliances Found in washing machines, fans, and refrigerators, where reliability is paramount.

Benefits of Using the 6212 Bearing

1. Efficiency The deep groove design facilitates smooth rotation, reducing friction and heat generation even at high speeds. 2. Durability Made with high-quality materials, the 6212 bearing is resistant to wear and can handle substantial loads. 3. Versatility Its dimensions and design make it suitable for a broad range of applications across different industries. 4. Maintenance-Free Options With sealed variants available, businesses can reduce downtime and maintenance costs.

Conclusion

The 6212 bearing's specifications make it a crucial component in many mechanical systems. Its combination of durability, efficiency, and versatility provides significant advantages in both industrial and consumer applications. When selecting bearings for your application, understanding the specifications and characteristics of products like the 6212 bearing is vital for ensuring optimal performance and longevity. By choosing the right type of bearing, engineers and manufacturers can contribute to the overall efficiency and reliability of their machinery, leading to enhanced productivity and reduced operational costs.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025