Jan . 16, 2025 04:35 Back to list

Deep Groove Ball Bearings

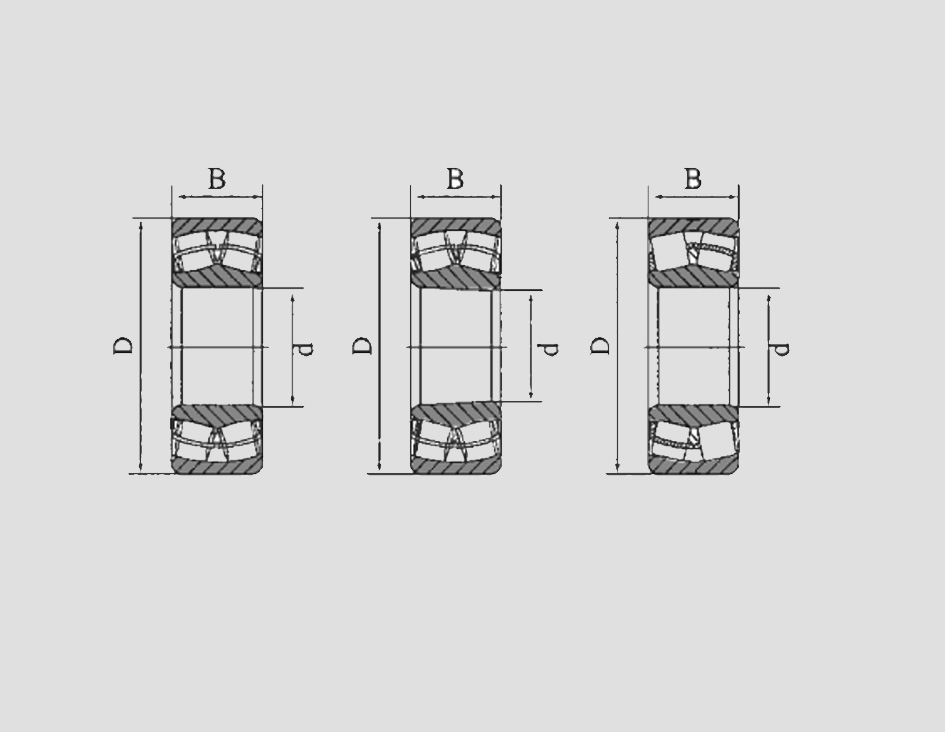

Navigating the intricate world of bearings requires a comprehensive understanding of their dimensions and specifications. The 6209 bearing is a widely-recognized component in various machinery and industrial applications, known for its reliability and efficiency. Its dimensions and attributes play a crucial role in ensuring optimal performance and durability, aspects that are often underestimated by those new to the subject.

The question of selecting the right material for the 6209 bearing is integral to its functioning and lifespan. Common materials include high-grade steel, which offers a good balance of strength and resistance to fatigue. However, in situations where corrosion resistance is a priority, stainless steel variants might be preferable, albeit with a potential trade-off in load capacity. Enhancing the bearing's reliability is also about understanding the interplay of its components. The cage material, another critical aspect, is often made of steel or plastic. Steel cages are chosen for high-load or high-temperature scenarios, providing robustness and stability. Meanwhile, plastic cages offer quieter operation and lighter weight, an asset in precision equipment where noise and unnecessary weight are concerns. The trustworthiness of a 6209 bearing not only depends on the manufacturer's credibility but also on how well the specification matches the application specifics. It's not uncommon for failures to occur due to mismatches in expected performance versus operational reality, underlining the importance of consulting with a specialist when in doubt. In summary, the 6209 bearing should never be chosen based solely on its dimensions. It requires an understanding of the operational context—speed, load, environment, and maintenance schedule. Proper selection and implementation of this bearing can significantly improve machinery performance, reduce downtime, and increase overall productivity. As professionals committed to engineering excellence and efficient system design, investing time in understanding these nuances is not just advisable; it is indispensable for ensuring the longevity and effectiveness of industrial applications.

The question of selecting the right material for the 6209 bearing is integral to its functioning and lifespan. Common materials include high-grade steel, which offers a good balance of strength and resistance to fatigue. However, in situations where corrosion resistance is a priority, stainless steel variants might be preferable, albeit with a potential trade-off in load capacity. Enhancing the bearing's reliability is also about understanding the interplay of its components. The cage material, another critical aspect, is often made of steel or plastic. Steel cages are chosen for high-load or high-temperature scenarios, providing robustness and stability. Meanwhile, plastic cages offer quieter operation and lighter weight, an asset in precision equipment where noise and unnecessary weight are concerns. The trustworthiness of a 6209 bearing not only depends on the manufacturer's credibility but also on how well the specification matches the application specifics. It's not uncommon for failures to occur due to mismatches in expected performance versus operational reality, underlining the importance of consulting with a specialist when in doubt. In summary, the 6209 bearing should never be chosen based solely on its dimensions. It requires an understanding of the operational context—speed, load, environment, and maintenance schedule. Proper selection and implementation of this bearing can significantly improve machinery performance, reduce downtime, and increase overall productivity. As professionals committed to engineering excellence and efficient system design, investing time in understanding these nuances is not just advisable; it is indispensable for ensuring the longevity and effectiveness of industrial applications.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025