Jan . 28, 2025 06:16 Back to list

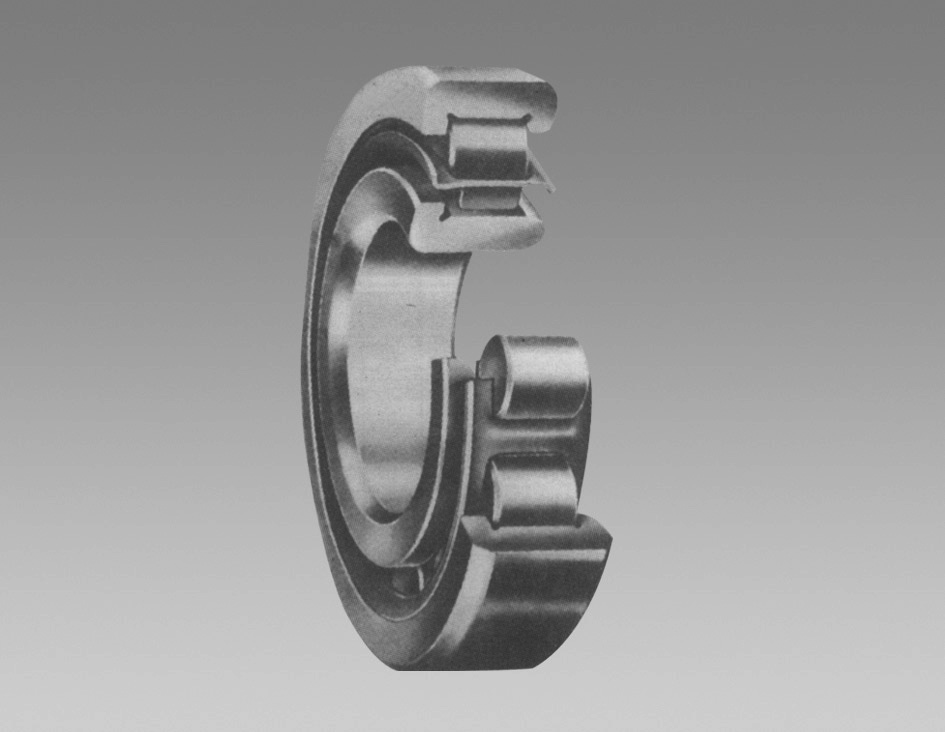

Spherical Roller Bearings

Choosing the perfect bearing size for your application can dramatically affect the efficiency and longevity of your machinery. The 6010 bearing size, a popular choice in countless industries, offers the right balance of strength, durability, and versatility, especially for applications with moderate loads and speeds.

Field experiences reveal that industries such as automotive, aerospace, and industrial machinery have leveraged the strengths of the 6010 bearing effectively. Engineers operating in these sectors appreciate the bearing's performance in accommodating misalignments that occur due to structural flexing or shock loads, thus protecting adjacent components and reducing overall maintenance costs. The ease of installation and replacement is another reason why the 6010 continues to be favored in maintenance schedules and installation guidelines. Moreover, technological advancements have heralded an age where predictive maintenance and condition monitoring further enhance the longevity of a 6010 bearing. Using sensors and diagnostic tools, operators can track the health of these bearings in real-time, allowing for preemptive interventions that prevent failures, boost performance, and ensure safety. This capability transforms the 6010 bearing from merely a mechanical component to a crucial contributor to digital manufacturing ecosystems. Trust in the 6010 bearing also stems from its broad acceptance and usage in diverse applications globally. Expert endorsements and case studies often cite its successful implementation in high-stakes environments, reinforcing its authoritative position in the bearing market. This empirical evidence, coupled with continual innovation in materials and design, fortifies the 6010 bearing as an indispensable component for modern engineering solutions. In conclusion, selecting the right bearing size transcends simple dimensional fits; it's a critical decision that impacts performance, reliability, and ultimately, the success of an operation. The 6010 bearing, with its proven track record, standardization, and innovative support systems, ensures that engineers and procurement specialists can make informed, dependable choices for their projects. As industries continue to evolve, the adaptability and enduring reliability of the 6010 bearing will remain vital, catering to advancements and sustaining productivity across a plethora of applications.

Field experiences reveal that industries such as automotive, aerospace, and industrial machinery have leveraged the strengths of the 6010 bearing effectively. Engineers operating in these sectors appreciate the bearing's performance in accommodating misalignments that occur due to structural flexing or shock loads, thus protecting adjacent components and reducing overall maintenance costs. The ease of installation and replacement is another reason why the 6010 continues to be favored in maintenance schedules and installation guidelines. Moreover, technological advancements have heralded an age where predictive maintenance and condition monitoring further enhance the longevity of a 6010 bearing. Using sensors and diagnostic tools, operators can track the health of these bearings in real-time, allowing for preemptive interventions that prevent failures, boost performance, and ensure safety. This capability transforms the 6010 bearing from merely a mechanical component to a crucial contributor to digital manufacturing ecosystems. Trust in the 6010 bearing also stems from its broad acceptance and usage in diverse applications globally. Expert endorsements and case studies often cite its successful implementation in high-stakes environments, reinforcing its authoritative position in the bearing market. This empirical evidence, coupled with continual innovation in materials and design, fortifies the 6010 bearing as an indispensable component for modern engineering solutions. In conclusion, selecting the right bearing size transcends simple dimensional fits; it's a critical decision that impacts performance, reliability, and ultimately, the success of an operation. The 6010 bearing, with its proven track record, standardization, and innovative support systems, ensures that engineers and procurement specialists can make informed, dependable choices for their projects. As industries continue to evolve, the adaptability and enduring reliability of the 6010 bearing will remain vital, catering to advancements and sustaining productivity across a plethora of applications.

Next:

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025