Nov . 25, 2024 22:43 Back to list

6006 zz bearing dimensions

Understanding the 6006 ZZ Bearing Dimensions A Detailed Overview

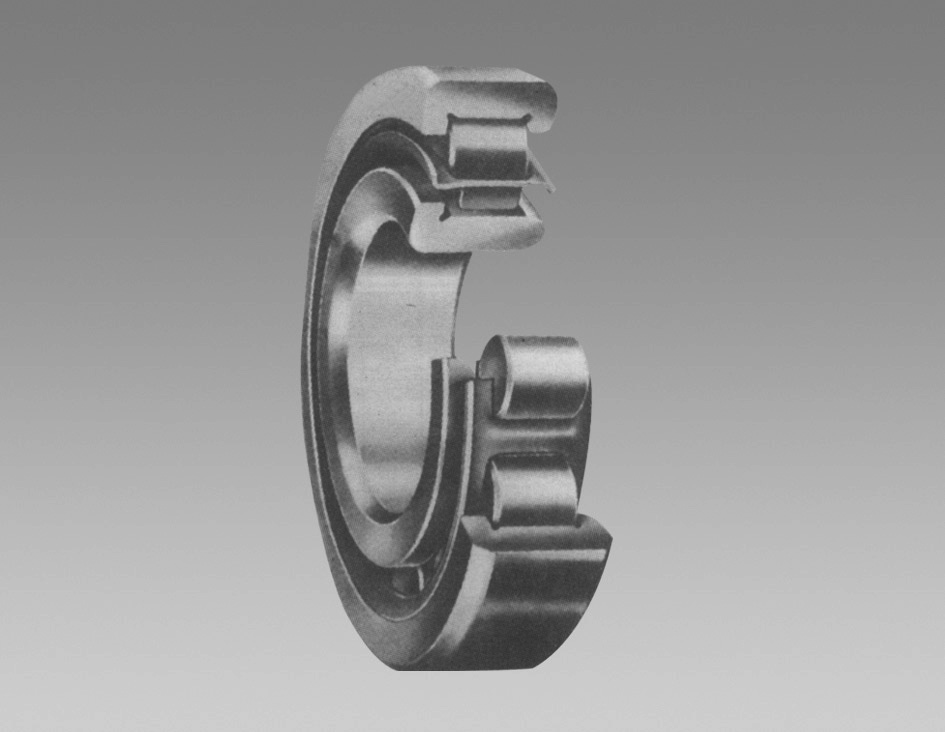

Bearings are essential components in various mechanical systems, playing a critical role in reducing friction between moving parts. Among the many types of bearings available today, the 6006 ZZ bearing is widely recognized for its robustness and versatility. This article delves into the dimensions, specifications, and applications of the 6006 ZZ bearing, providing an in-depth understanding of its features.

What is a 6006 ZZ Bearing?

The 6006 ZZ bearing is a deep groove ball bearing, characterized by its simple design and ability to withstand both radial and axial loads. The 6006 designation refers to its size and series, while ZZ denotes that it has metal shields on both sides to protect the internal components from contaminants such as dirt and moisture.

Dimensions of the 6006 ZZ Bearing

To provide a detailed perspective, let’s break down the dimensions of the 6006 ZZ bearing

1. Inner Diameter (ID) The inner diameter of a 6006 ZZ bearing is 30 mm. This is the diameter of the hole in the center of the bearing where the shaft fits.

2. Outer Diameter (OD) The outer diameter measures 55 mm. This is the total width of the bearing from one outer edge to the other.

3. Width (Thickness) The bearing has a width of 13 mm. This measurement reflects the thickness of the bearing itself.

4. Weight The typical weight of a 6006 ZZ bearing is about 0.18 kg. While this may seem small, it plays a significant role in various applications.

5. Load Capacity The bearing is designed to handle a dynamic load rating of approximately 18,500 N. This means it can support considerable loads while maintaining performance.

Material and Construction

6006 zz bearing dimensions

The 6006 ZZ bearing is constructed from high-quality steel, which offers excellent durability and resistance to wear. The internal components consist of steel balls that revolve around a raceway, helping to minimize friction. The shielding (ZZ) provided on either side helps to keep lubricants in and prevent debris from contaminating the bearing’s interior.

Advantages of Using 6006 ZZ Bearings

1. Versatility Due to its size and construction, the 6006 ZZ bearing can be used in a variety of applications, including electric motors, household appliances, automotive systems, and industrial machines.

2. Reduced Friction The ball design allows for smoother rotation and less friction compared to other bearing types. This results in improved efficiency and longevity.

3. Protection Against Contaminants The shields on either side effectively protect the internal components from dust and moisture, extending the operational life of the bearing.

4. Maintenance-Free The bearings are typically pre-lubricated and shielded, reducing the need for regular maintenance and thereby enhancing user convenience.

5. Easy Installation The standard dimensions make them compatible with a wide range of applications and easy to install in various mechanical assemblies.

Applications of 6006 ZZ Bearings

The 6006 ZZ bearing's characteristics make it ideal for numerous applications. Here are a few notable examples

- Electric Motors The bearing supports the rotor and allows for smooth rotation. - Agricultural Machinery Used in equipment that requires reliable and long-lasting performance under heavy loads. - Automotive Components Employed in power steering systems, air conditioning units, and various other automotive applications. - Conveyor Systems The bearing supports rollers in conveyor belts, facilitating efficient movement of goods.

Conclusion

The 6006 ZZ bearing stands out due to its reliable performance, ease of use, and versatility across a range of applications. Its dimensions, coupled with its robust construction and maintenance-free design, make it an excellent choice for engineers and manufacturers alike. Understanding the specifications and applications of the 6006 ZZ bearing helps in making informed decisions when selecting the right bearing for specific mechanical needs. By choosing the right bearing, you can ensure enhanced efficiency and longevity in your mechanical systems.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025