Dec . 14, 2024 16:56 Back to list

Dimensions and Specifications for 6000z Bearings in Mechanical Applications

Understanding the Dimensions of 6000Z Bearings

Bearings play a crucial role in the functioning of machinery across various industries. One popular type of bearing is the deep groove ball bearing, which is engineered for both radial and axial loads. The 6000Z bearing series is particularly noteworthy due to its versatility and reliability. In this article, we will delve into the dimensions and characteristics of 6000Z bearings, elaborating on their significance in machinery.

Structure and Design

The 6000Z bearing is part of the larger series of 6000 bearings, which are commonly used in electric motors, household appliances, and various types of equipment. The designation Z indicates that the bearing is shielded on one side. This shielding provides protection against dust and debris, ensuring prolonged lifespan and reduced maintenance. The specific design allows for higher speeds and efficiency, making the 6000Z bearing a popular choice for manufacturers.

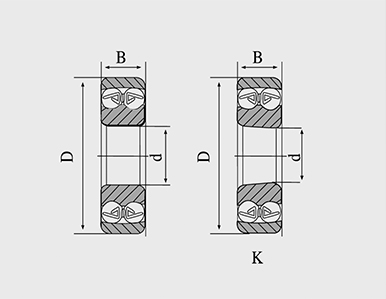

Dimensions

The standard dimensions of a 6000Z bearing are as follows

- ID (Inner Diameter) 10 mm - OD (Outer Diameter) 26 mm - Width (Thickness) 8 mm

These dimensions make the 6000Z bearing compact, allowing it to fit into tight spaces while still providing robust support. The inner diameter is carefully engineered to fit onto shafts, while the outer diameter enables the bearing to fit securely within housing.

Load Capacity

6000z bearing dimensions

Another important aspect of the 6000Z bearing is its load capacity. Deep groove ball bearings can withstand significant radial and axial loads. The load ratings are generally specified in terms of dynamic and static loads. For a 6000Z bearing, the dynamic load rating is typically around 4,600 N, while the static load rating can reach approximately 2,300 N. This makes the 6000Z bearing suitable for a plethora of applications, from high-speed machinery to slower-moving devices.

Material and Performance

The material used in the manufacturing of 6000Z bearings is crucial to their performance. Usually, these bearings are made from high-carbon chromium steel, which offers excellent durability and wear resistance. This material ensures that the bearing can operate under varying environmental conditions. Furthermore, the use of pre-lubricated greases helps in maintaining optimal performance, reducing friction and wear.

Applications

Owing to their dimensions and robust design, 6000Z bearings are widely used in various applications. They are commonly found in

- Electric motors - Fans and blowers - Pumps and compressors - Robotics - Automotive components

The adaptability of the 6000Z bearing allows it to function efficiently in both industrial and domestic settings.

Conclusion

In summary, the 6000Z bearing is a vital component in numerous machines and applications, deriving its importance from its compact dimensions, load capacity, and protective shielding. As industries continue to evolve and machinery becomes more advanced, bearings like the 6000Z will undoubtedly play an integral role in ensuring efficiency and reliability. Understanding its specifications allows engineers and manufacturers to select the appropriate bearings for their specific needs, enhancing both performance and longevity of their machinery. As a result, the exploration of 6000Z bearing dimensions becomes not just a technical necessity, but a pathway towards innovation in design and functionality in various fields.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025