Nov . 23, 2024 09:47 Back to list

51305 bearing

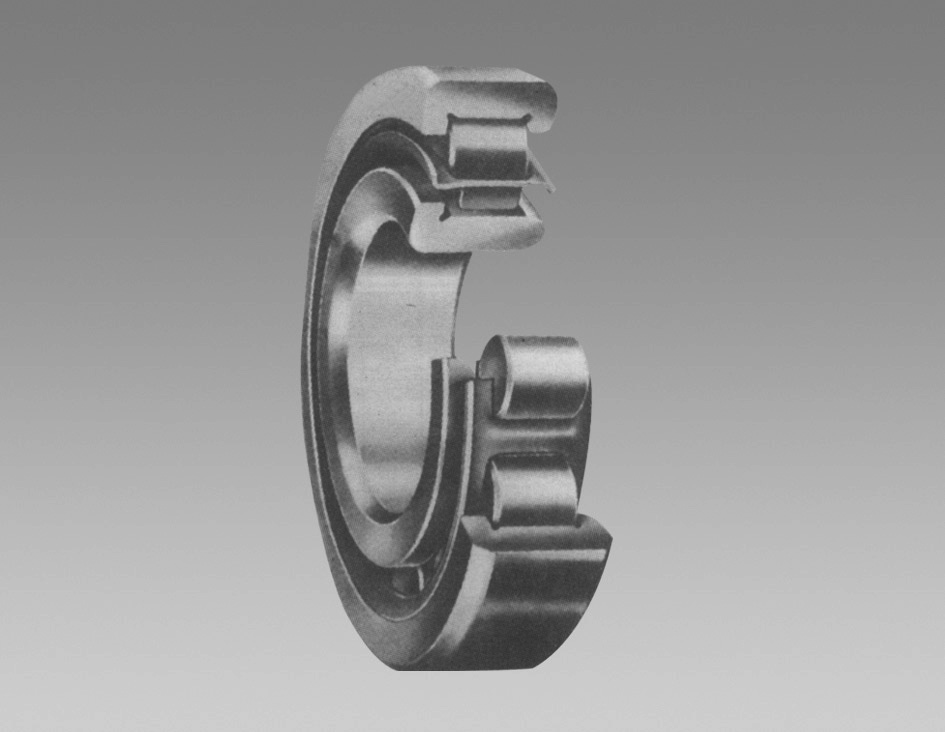

Understanding the 51305 Bearing An In-Depth Analysis

In the realm of engineering and machinery, bearings play a crucial role in the efficient functioning of rotating components. Among the vast array of bearings, the 51305 bearing has garnered attention for its unique characteristics and applications. This article delves into the specifications, applications, advantages, and maintenance of the 51305 bearing, providing a comprehensive overview for engineers and enthusiasts alike.

Specifications of the 51305 Bearing

The 51305 bearing is a type of thrust ball bearing, designed to accommodate axial loads in one direction. It consists of two raceways—one located in the bearing housing and the other in the ball assembly. The designation “51305” indicates specific dimensions and load capacities, while “ ” refers to the encoding used in URL representations, which is not typically relevant in standard bearing discussions.

The dimensions of the 51305 bearing typically include an inner diameter of approximately 25 mm, an outer diameter of around 42 mm, and a width of 19 mm. Its design allows it to support high static and dynamic load capacities while maintaining smooth operation at various speeds. The bearing is usually constructed from high-quality steel, providing durability and strength essential for industrial applications.

Applications of the 51305 Bearing

The versatility of the 51305 bearing makes it suitable for a diverse range of applications. It is commonly used in machinery where axial loads are predominant, such as in gear assemblies, automotive applications, and industrial equipment. In addition to these uses, the bearing is also employed in robotics, conveyors, and even aerospace applications where precision and reliability are paramount.

In automotive applications, the 51305 bearing may be found in power steering systems, where it aids in the directional control of the vehicle. In industrial settings, it often plays a role in supporting the shafts of rotating machinery, ensuring that motion is transferred smoothly and efficiently. Furthermore, the ability to withstand high thermal and mechanical stresses makes it ideal for heavy-duty applications.

51305 bearing

Advantages of the 51305 Bearing

One of the primary advantages of the 51305 bearing is its ability to handle high axial loads, making it an efficient choice for numerous applications. Additionally, its design promotes reduced friction, leading to minimal energy losses during operation. This efficiency translates into lower operational costs and increased reliability of machinery.

Another notable advantage is its maintenance free operation. Many variants of the 51305 bearing come pre-greased and sealed, which reduces the need for regular maintenance interventions. This feature not only saves time and effort but also prolongs the bearing's lifespan, thereby enhancing the overall efficiency of the system in which it is employed.

Maintenance Considerations

While the 51305 bearing is designed for durability and low maintenance, certain practices can optimize its lifespan and performance. Regular inspections are crucial to ensure that there is no unusual wear or damage. Operators should monitor for signs of overheating or abnormal noise, as these may indicate underlying issues that require immediate attention.

In applications where the bearing is subjected to harsh environmental conditions, additional protective measures such as seals or shields may be beneficial. These can help to prevent contaminants from entering the bearing, which could lead to premature failure.

Conclusion

In summary, the 51305 bearing stands out as a robust and versatile component often utilized in various industrial and automotive applications. Its ability to handle high axial loads, coupled with low maintenance requirements, makes it an excellent choice for engineers looking for reliable performance in demanding environments. By understanding the specifications, applications, advantages, and maintenance of the 51305 bearing, users can make informed decisions that enhance the efficiency and longevity of their machinery. As technology advances, the role of such bearings will continue to be vital in the pursuit of innovation and efficiency across industries.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025