Nov . 22, 2024 18:47 Back to list

51120 thrust bearing

Understanding the 51120 Thrust Bearing Applications and Benefits

Thrust bearings play a crucial role in various machinery and mechanical systems by allowing rotation while supporting axial loads. Among the various types of thrust bearings, the 51120 thrust bearing has gained prominence due to its unique design and functionality. This article delves into the specifics of the 51120 thrust bearing, exploring its applications, advantages, and maintenance considerations.

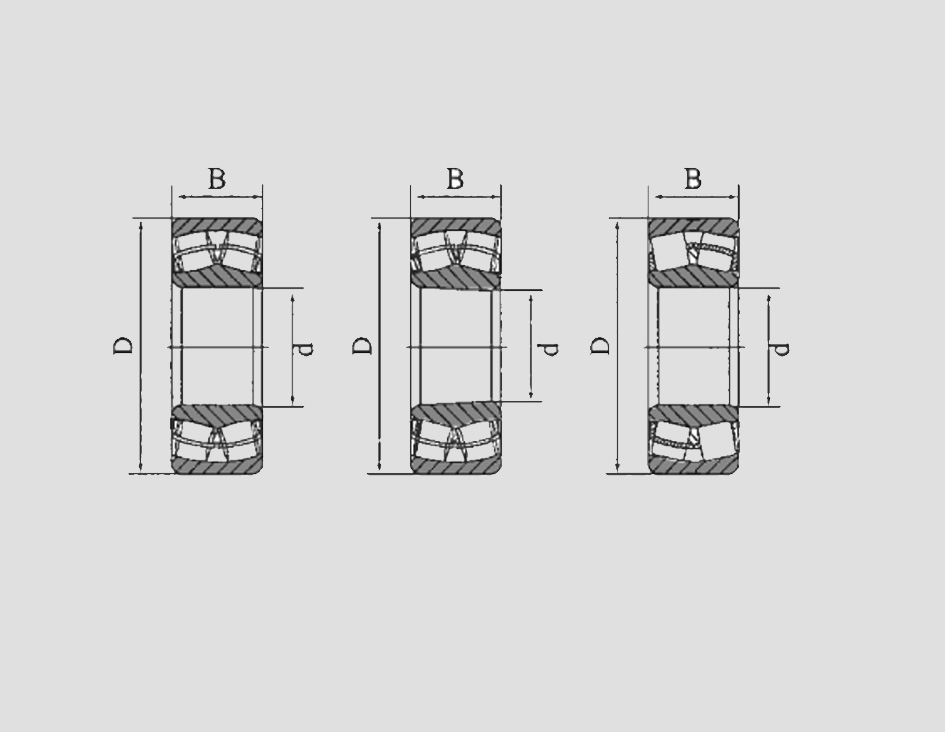

The 51120 thrust bearing is typically a cylindrical roller bearing that is designed to accommodate axial loads in one direction. These bearings are engineered with a sturdy outer ring and a cage that holds cylindrical rollers in place, effectively distributing the load across the surface area. This specific design enhances the bearing's ability to handle higher loads and reduces the risk of wear and tear, making it a preferred choice in various industrial applications.

One of the primary applications of the 51120 thrust bearing can be found in the automotive industry

. It is often used in manual transmission systems, where it helps support the thrust loads generated by the gears during operation. Additionally, these bearings are used in electric motors, where they ensure smooth performance and longevity by stabilizing the axial load on the shaft.51120 thrust bearing

In the industrial sector, the 51120 thrust bearing is commonly employed in machinery such as crushers, hoists, and conveyors. These applications require reliable support for heavy axial loads, and the robust design of the 51120 thrust bearing makes it an ideal choice. Moreover, its capacity to operate at high speeds adds to its versatility, enabling usage in various machinery settings.

The advantages of using the 51120 thrust bearing extend beyond its load-bearing capabilities. For instance, its cylindrical roller design allows for lower friction, which translates to less heat generation during operation. This characteristic not only improves efficiency but also prolongs the life of the bearing itself. Furthermore, the 51120 thrust bearing can operate effectively in challenging environments, including those exposed to moisture or dust, by utilizing materials that can withstand corrosion and contamination.

Maintenance of the 51120 thrust bearing is relatively straightforward, yet it plays a critical role in ensuring optimal performance. Regular lubrication is essential to reduce friction and wear. Operators should select the appropriate lubricant based on the operational environment and load requirements. Additionally, periodic inspections for signs of wear, misalignment, or damage can help identify potential issues before they escalate, thus minimizing downtime and repair costs.

In conclusion, the 51120 thrust bearing stands out as a reliable and efficient solution for managing axial loads in various applications. Its robust construction, adaptability to high-speed operations, and ease of maintenance make it a vital component across numerous industries. As technology continues to evolve, the demand for effective thrust bearings like the 51120 will undoubtedly grow, highlighting the importance of understanding these components for improved mechanical performance. Whether in automotive applications or heavy machinery, the role of the 51120 thrust bearing is indispensable, underscoring the significance of proper design and maintenance in engineering.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025