Dec . 10, 2024 10:18 Back to list

51114 bearing

Understanding the 51114 Bearing Features, Applications, and Maintenance

Bearings are critical components in various machinery and equipment, allowing for smooth rotational or linear movement. One commonly used type of bearing in industrial applications is the 51114 bearing. This article delves into the specifications, applications, and maintenance practices related to the 51114 bearing, providing a comprehensive overview for engineers and enthusiasts alike.

Specifications of the 51114 Bearing

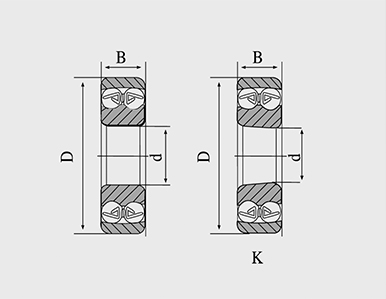

The 51114 bearing is classified as a thrust roller bearing, designed to accommodate axial loads in one direction. Its primary dimensions include a bore size of 70 mm, an outer diameter of 95 mm, and a width of 20 mm. The bearing is composed of a thrust washer and several cylindrical rollers arranged to maximize the surface area in contact with the washer, allowing for efficient load distribution. The cylindrical rollers also reduce friction, enabling smoother operation under high axial loads.

The material composition of the 51114 bearing typically involves high-carbon chromium steel, which provides excellent wear resistance and durability. Many manufacturers also use special coatings or materials to improve corrosion resistance, especially for applications in harsh environments. The operating temperature range for this type of bearing is generally between -20°C to 120°C, making it suitable for various industrial conditions.

Applications of the 51114 Bearing

Due to its unique design and ability to handle axial loads efficiently, the 51114 bearing finds applications in a variety of machinery and equipment. It is commonly used in

1. Automotive Industry The 51114 bearing is utilized in automotive components such as clutch assemblies and gearbox systems, where axial loads are prevalent. Its robust design helps ensure smooth operation and prolongs the lifespan of mechanical systems.

2. Industrial Machinery In industries such as manufacturing, the 51114 bearing is used in conveyor systems, mixing equipment, and other machinery that requires high axial load capacity. The bearing’s ability to maintain performance under stress is critical for optimizing production efficiency.

3. Agricultural Equipment Agricultural machinery, such as tractors and harvesters, relies on the 51114 bearing to support various moving parts. The ability to withstand harsh conditions, including dirt and moisture, makes this bearing a reliable choice for farmers.

51114 bearing

4. Marine Applications In marine environments, where corrosion resistance is vital, the 51114 bearing is often employed in equipment like winches and steering systems. It helps ensure smooth operation while enduring the challenges of saltwater exposure.

Maintenance of the 51114 Bearing

To ensure the longevity and optimal performance of the 51114 bearing, regular maintenance is essential. Here are some best practices

1. Lubrication Proper lubrication is crucial to minimize friction and wear. Bearings can be lubricated using grease or oil, depending on the application and operating conditions. Regularly check the lubrication levels and replenish as needed.

2. Monitoring Performance Keep an eye on the bearing's performance. Any unusual noises, vibrations, or temperature fluctuations can indicate potential issues. Early detection of problems can prevent catastrophic failures.

3. Regular Inspections Schedule regular inspections to check for wear and tear. Look for signs of damage such as pitting, discoloration, or deformation of the bearing surfaces. If any abnormalities are detected, consider replacing the bearing to avoid further damage to the equipment.

4. Clean Environment Maintaining a clean operating environment can significantly enhance the life of the bearing. Ensure that contaminants such as dirt, dust, and moisture are minimized.

Conclusion

The 51114 bearing is a versatile and robust component widely used across various industries due to its ability to handle high axial loads efficiently. Understanding its specifications, applications, and maintenance practices can help engineers and technicians ensure optimal performance and longevity of machinery. By adhering to proper maintenance protocols, users can maximize the benefits of the 51114 bearing, ultimately contributing to improved operational efficiency.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025