Nov . 05, 2024 22:07 Back to list

4208 Bearing Specs and Measurements for Optimal Performance and Compatibility

Understanding the Dimensions of 4208 Bearings

Bearings are essential components in various mechanical systems, enabling smooth rotation of parts while minimizing friction. One specific type of bearing that has garnered attention in many industries is the 4208 bearing. Understanding the dimensions and specifications of this bearing type is crucial for engineers, manufacturers, and anyone involved in machinery maintenance.

What is a 4208 Bearing?

The term 4208 typically refers to a specific dimensional configuration of a double-row angular contact ball bearing. Bearings of this designation are used in a wide variety of applications, including automotive, aerospace, industrial machinery, and more. The structure of these bearings allows them to handle both axial and radial loads effectively, which is essential for applications where high speed and precision are required.

Key Dimensions of the 4208 Bearing

The dimensions of a bearing like the 4208 include critical measurements that dictate its performance and suitability for different applications. Here are the key specifications

1. Inner Diameter (ID) The inner diameter of the 4208 bearing is typically designed to fit around a shaft. Commonly, this measurement would be around 40 mm; however, it can slightly vary based on the manufacturer.

2. Outer Diameter (OD) The outer diameter is another crucial dimension that often measures approximately 80 mm. This is important for ensuring that the bearing fits into the designated housing or structure.

3. Width (B) The width of the bearing, which affects how much load it can handle and its overall stability, usually measures around 18 mm.

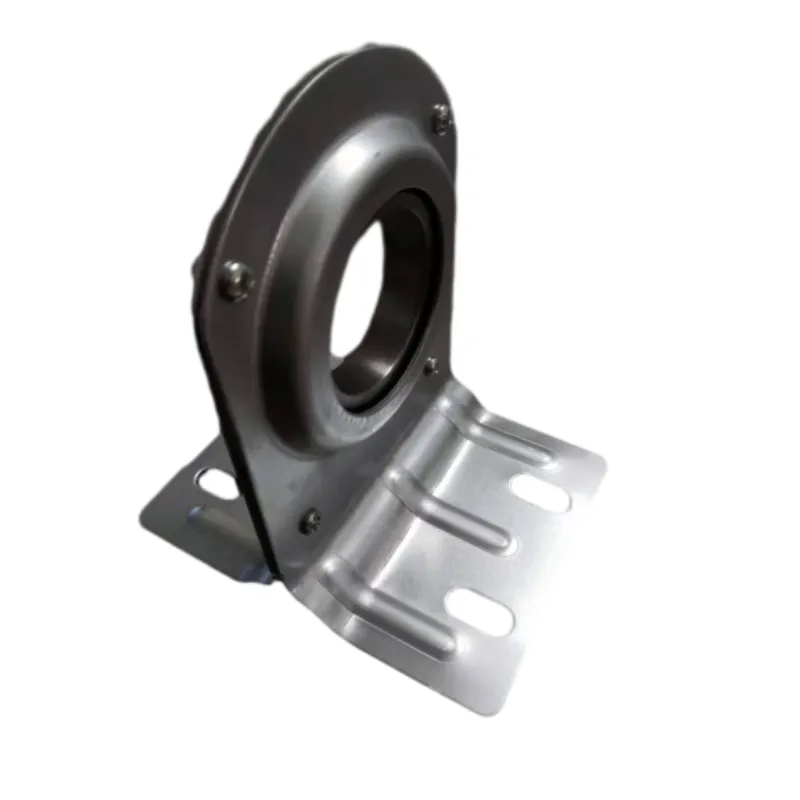

4208 bearing dimensions

4. Load Ratings Load ratings are integral to understanding the performance capabilities of the 4208 bearing. The dynamic load rating, which indicates how much load a bearing can withstand while rotating, is typically rated at around 28 kN. The static load rating refers to the load capacity when the bearing is stationary, which can be significantly higher, around 35 kN.

5. Operating Temperature Another important factor to consider is the temperature range in which the bearing can operate effectively. The 4208 bearings are usually designed to withstand temperatures ranging from -30°C to +120°C.

Applications of the 4208 Bearing

Given its robust design and specified dimensions, the 4208 bearing is suited for a range of applications. Some of the most common include

- Automotive Industry In vehicle engines, gears, and other rotating components where both load and speed are significant factors. - Industrial Machinery Used in conveyor systems, pumps, and motors where dual load handling is essential. - Aerospace Applications Permitting precise movements in systems requiring reliability under extreme conditions. The versatility of the 4208 bearing makes it a preferred choice among engineers and designers seeking efficient and reliable components for advanced machinery.

Maintenance and Longevity

While the 4208 bearing is designed for durability, maintenance is key to ensuring its longevity. Regular inspection for wear, proper lubrication, and monitoring for any unusual noises or vibrations can help extend the life of the bearing. Additionally, ensuring that the bearing is installed correctly to prevent misalignment can reduce premature wear.

Conclusion

In summary, understanding the dimensions and specifications of the 4208 bearing is vital for anyone involved in mechanical design, equipment maintenance, or manufacturing. With its specific measurements and capabilities, this bearing efficiently withstands various loads, making it invaluable in many applications. Ensuring proper maintenance practices will guarantee optimal performance and longevity, cementing the 4208 bearing's role as a critical component in modern mechanical systems. Whether you are designing new machinery or maintaining existing equipment, knowing the ins and outs of these bearings can lead to improved performance and reliability.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025