Dec . 22, 2024 06:53 Back to list

4206 bearing dimensions

Understanding 4206 bearing dimensions and Their Application

Bearings play a crucial role in machinery and equipment, allowing for the smooth rotation of shafts and minimizing friction between moving parts. Among various types of bearings, the 4206 bearing stands out due to its unique dimensions and functional characteristics. Understanding the dimensions and specifications of the 4206 bearing can help engineers and technicians select the right component for their applications, ensuring optimal performance and longevity.

Overview of 4206 Bearings

The 4206 bearing is classified as a double-row bearing, specifically a deep groove ball bearing. This type of bearing is designed to accommodate both radial and axial loads, which makes it extremely versatile. It is widely used in automotive applications, industrial machinery, and even in home appliances due to its reliable performance and ability to function under various conditions.

Key Dimensions

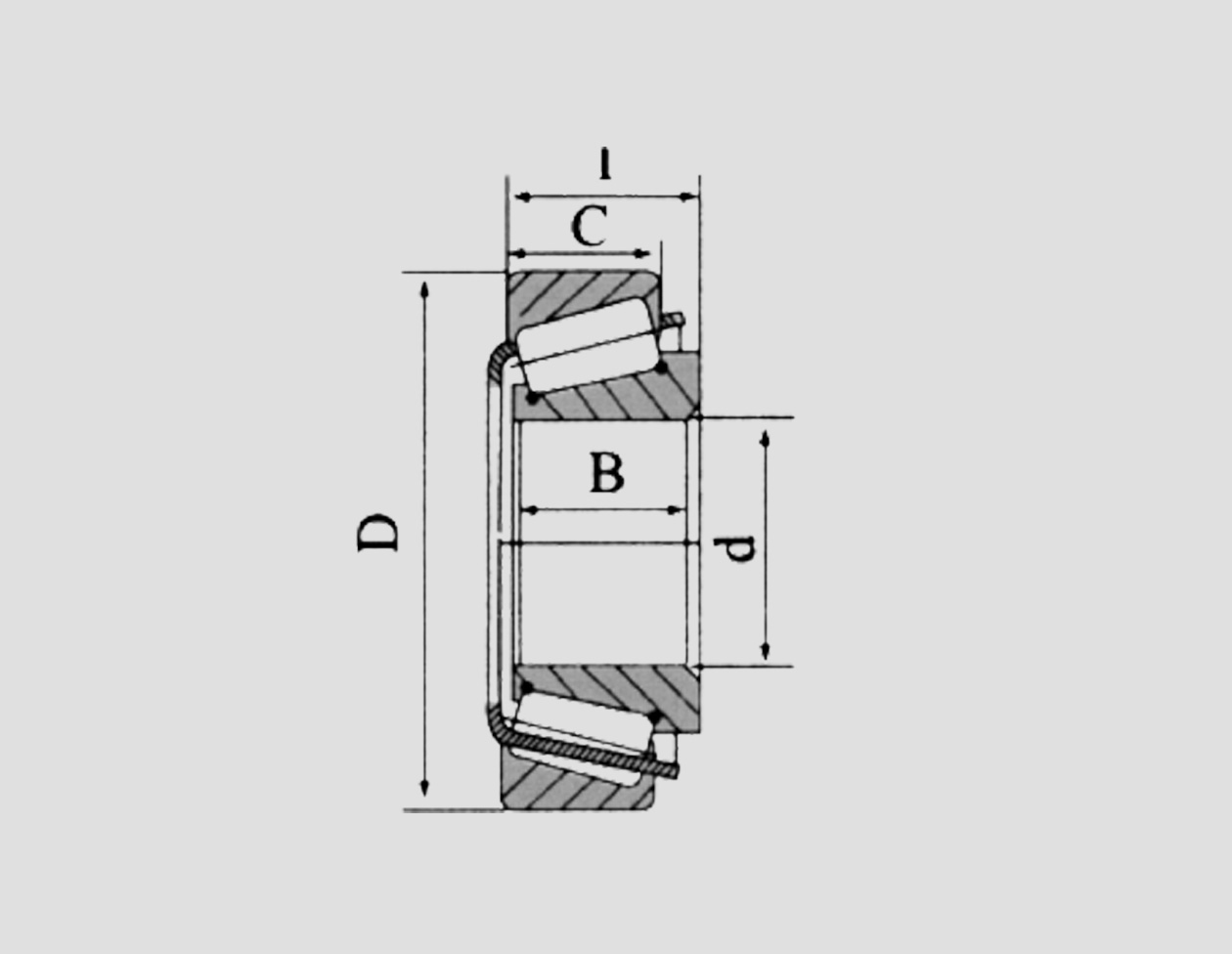

To comprehend the functionality of the 4206 bearing, one must understand its dimensions and technical specifications. The typical dimensions for a 4206 bearing include

- Inner Diameter (d) 30 mm - Outer Diameter (D) 62 mm - Width (B) 16 mm

These dimensions are crucial as they dictate the bearing’s load capacity and overall performance. The inner diameter indicates the size of the shaft that the bearing can fit onto, while the outer diameter determines how much space the bearing occupies within the housing. The width of the bearing contributes to its ability to handle loads and maintain stability during operation.

Load Ratings

The load ratings for a 4206 bearing are generally categorized into dynamic and static load ratings

- Dynamic Load Rating (C) This rating indicates the maximum load that the bearing can withstand while in motion. For the 4206 bearing, the dynamic load rating is typically around 30,000 N. - Static Load Rating (C0) This rating signifies the maximum load the bearing can tolerate when stationary. For the 4206 bearing, it usually falls around 19,000 N.

4206 bearing dimensions

Understanding these load ratings is essential for engineers when designing systems, as exceeding these limits can result in premature bearing failure.

Materials and Construction

The performance of the 4206 bearing also depends on the materials used in its construction. Most commonly, these bearings are made from high-quality carbon steel or stainless steel, which provide strength and resistance to wear. In specialized applications, ceramic materials may be used to enhance performance further, especially at high temperatures or in corrosive environments.

Lubrication and Maintenance

Proper lubrication is vital for the longevity of any bearing, including the 4206. Lubricants reduce friction and wear between the moving parts and can significantly extend the bearing's lifespan. Regular inspection and maintenance can help identify potential issues such as excessive wear or contamination, allowing for timely intervention.

Applications of the 4206 Bearing

The versatility of the 4206 bearing makes it suitable for a wide range of applications. Here are some common areas where it is utilized

- Automotive Industry In vehicles, 4206 bearings are often found in wheel hubs, transmissions, and auxiliary components. - Industrial Machinery They are commonly used in conveyor belts, manufacturing equipment, and heavy machinery where robust performance is required. - Home Appliances Appliances such as washing machines and dryers frequently use 4206 bearings to facilitate smooth operation.

Conclusion

In summary, the 4206 bearing is an essential component widely used across various industries due to its favorable dimensions and load capacities. By understanding its specifications, materials, and applications, engineers can make informed decisions when selecting the right bearing for their specific needs. Proper maintenance and lubrication further ensure the reliability and efficiency of these bearings, making them indispensable in modern machinery. Whether in automotive, industrial, or domestic applications, the 4206 bearing continues to play a significant role in enhancing performance and durability.

Latest news

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025