Nov . 08, 2024 00:44 Back to list

High-Performance 40x80x30mm Ball Bearing for Efficient Machinery Applications

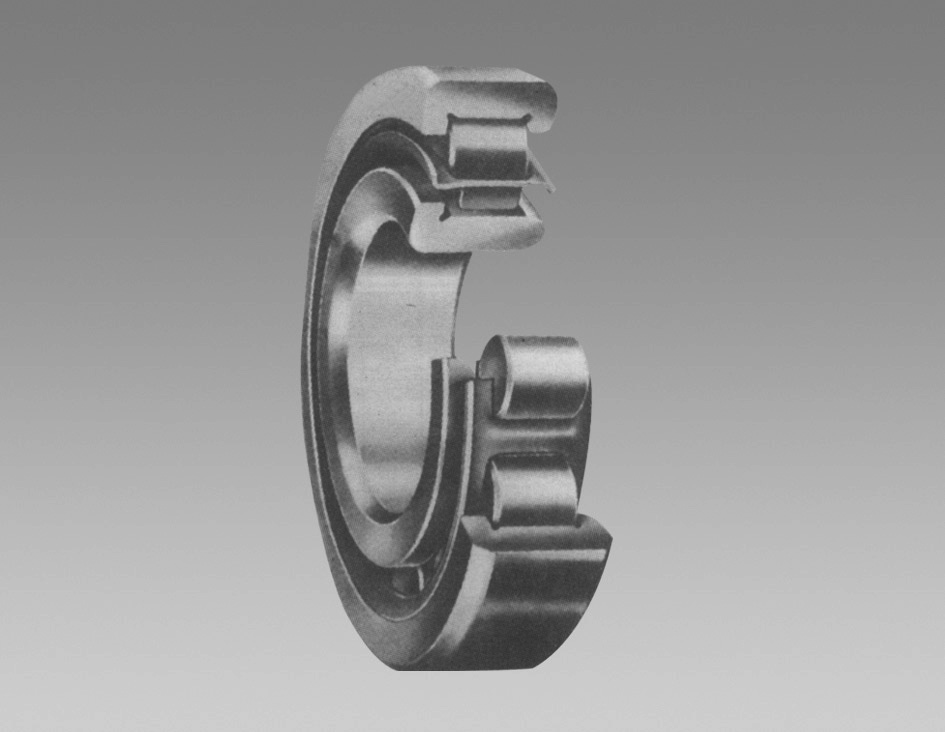

Understanding 40x80x30 Bearings A Comprehensive Guide

Bearings are fundamental components in machinery and equipment, allowing for smooth rotation and minimizing friction between moving parts. Among the many types of bearings available, the 40x80x30 bearing is one that stands out in terms of its specifications and applications. In this article, we will delve into what this bearing is, its dimensions, how it operates, and its various uses.

What is a 40x80x30 Bearing?

The designation 40x80x30 typically refers to the bearing's dimensions and specific characteristics. Here's a breakdown of the terminology

1. Dimensions The first part of the designation indicates the dimensions of the bearing. In this case, the bearing is 40 mm in inner diameter, 80 mm in outer diameter, and 30 mm in width. These measurements are crucial because they dictate where the bearing can be fitted and what types of loads it can handle.

2. 30 The remaining part of the designation, 30 , often refers to certain design features or tolerances related to the bearing's performance. This could involve load ratings, material properties, or specific manufacturing standards that modify its application suitability.

Bearings of this size are generally categorized as deep groove ball bearings, which are designed to support both radial and axial loads. They are versatile components used in a variety of industries.

Key Features and Benefits

Understanding the properties of 40x80x30 bearings helps in recognizing their advantages

- Load Capacity The size and design of the bearing allow it to sustain substantial loads while maintaining smooth operation. Depending on its material and design, it's capable of withstanding dynamic and static loads effectively.

- Durability Most 40x80x30 bearings are made from high-quality steel or ceramic materials, offering excellent resistance to wear and tear. This durability ensures that machinery operates consistently over long periods, reducing the need for frequent replacements.

40x80x30 bearing

- Versatility With such dimensions, these bearings find application across a wide range of machines—from electric motors to automotive components and industrial equipment. They can adapt to various operational environments, making them a preferred choice in many situations.

- Easy Maintenance Many bearings are sealed or shielded to prevent contaminants from entering, which simplifies maintenance. Users often benefit from less frequent lubrication and longer service intervals.

Applications

The 40x80x30 bearing has numerous applications across different sectors

1. Automotive Industry These bearings are commonly used in vehicle wheels, transmissions, and engine assemblies. Their ability to support heavy loads while minimizing friction plays a critical role in vehicle performance.

2. Industrial Machinery In factories, the bearing often features in conveyor systems, pumps, and other heavy machines. Its robust design helps in maintaining the efficiency of production lines.

3. Electric Motors Many small and large electric motors incorporate these bearings as they assist in facilitating smooth rotational motion, which is vital for motor efficiency.

4. Household Appliances The prevalence of these bearings in appliances like washing machines and refrigerators aids in preventing noise and vibration, enhancing user experience.

Conclusion

In summary, the 40x80x30 bearing is a key player in numerous mechanical and industrial applications. Understanding its dimensions, features, and potential uses enhances our appreciation of its role within various technologies. Whether in demanding industrial settings or common household appliances, these bearings ensure efficiency, durability, and reliability. As technology evolves, the importance of quality bearings like the 40x80x30 will only increase, fostering smooth operations across all types of machinery.

When selecting bearings for a particular application, it is essential to consider not only the size and fit but also the operational conditions they will face. This approach ensures that the bearing will perform optimally, prolong the life of the machinery, and lead to better overall performance.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025