Dec . 23, 2024 00:57 Back to list

Exploring the Features and Benefits of 387A and 382A Bearings for Optimal Performance

The 387A and 382A Bearings A Comprehensive Overview

In the realm of mechanical engineering, the importance of bearings cannot be overstated. Bearings are critical components that enable the smooth rotation of parts and minimize friction between moving surfaces. Among the various types of bearings available in the market, the 387A and 382A bearings hold a notable position due to their specific applications, durability, and overall performance characteristics.

Understanding 387A and 382A Bearings

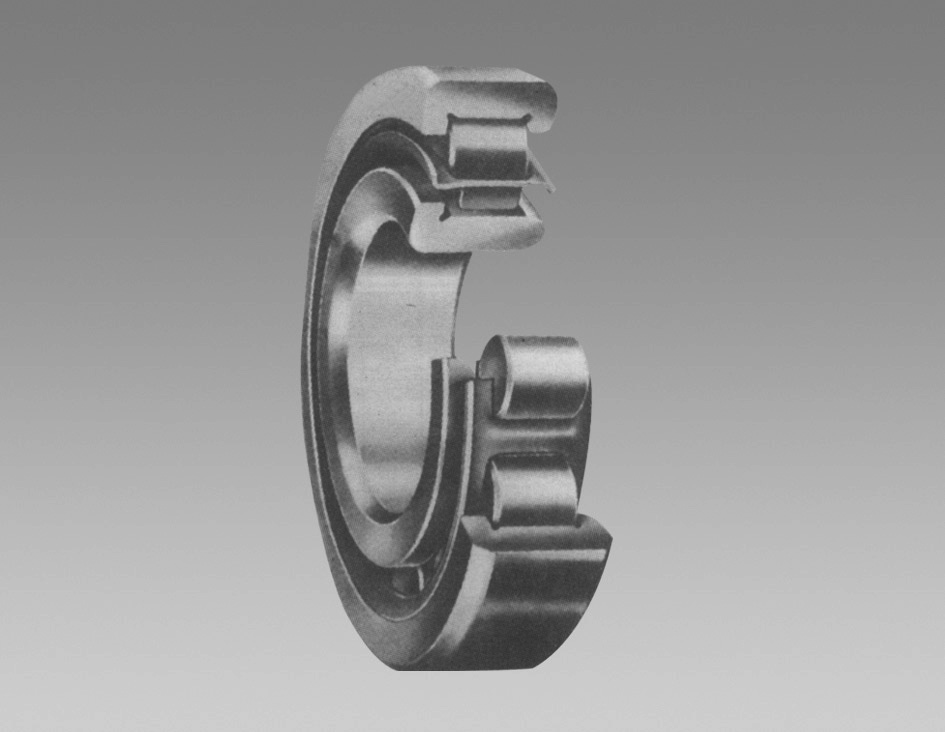

The 387A and 382A bearings are part of the tapered roller bearing family, which is designed to handle both radial and axial loads. These bearings consist of an inner and outer ring, rolling elements, and a cage that keeps the rolling elements evenly spaced. Tapered roller bearings are uniquely designed with a conical shape, allowing them to accommodate heavy loads while providing structural rigidity. The main difference between 387A and 382A bearings lies in their dimensions and load capacity, which can significantly impact their performance in specific applications.

Applications of 387A and 382A Bearings

The 387A and 382A bearings are widely used in various industries, including automotive, aerospace, and heavy machinery. In the automotive sector, they are often utilized in wheel hubs, differentials, and transmission systems, where excellent load support and durability are paramount. In heavy machinery, these bearings can be found in applications such as construction equipment, where they facilitate the smooth operation of rotating components under significant loads.

Additionally, these bearings are employed in certain aerospace applications, where precision and reliability are essential. The ability to handle both radial and axial loads makes the 387A and 382A bearings a preferred choice in applications where alignment issues and misalignment may occur.

Performance Characteristics

387a 382a bearing

One of the defining characteristics of the 387A and 382A bearings is their ability to perform well under varying conditions. These bearings exhibit excellent load-bearing capacity, enabling them to withstand the stresses encountered in heavy-duty applications. Additionally, they are often manufactured from high-quality materials, such as chrome steel or stainless steel, which contribute to their strength and resistance to wear.

Moreover, tapered roller bearings generally allow for a controlled and smooth movement, minimizing friction and heat generation even at high speeds. This not only prolongs the life of the bearings but also improves the overall efficiency of the machinery in which they are used.

Maintenance and Longevity

To ensure the longevity and optimal performance of 387A and 382A bearings, regular maintenance is crucial. This can include periodic inspections, lubrication, and, when necessary, replacement. Proper lubrication is especially important, as it reduces friction between the moving parts and helps to dissipate heat. Depending on the application, various lubrication methods can be employed, including oil baths, grease, or oil mist systems.

In many cases, users may choose to implement a preventive maintenance program, which can help identify potential issues before they lead to failure. Techniques such as vibration analysis can be beneficial in monitoring the condition of the bearings and ensuring their continued functionality.

Conclusion

In conclusion, the 387A and 382A bearings are integral components that play a significant role in the efficiency and effectiveness of many mechanical systems. Their ability to handle radial and axial loads, combined with their durability and performance characteristics, make them a popular choice across various industries. Proper maintenance and timely inspections can further enhance their performance and lifespan, making them a reliable choice for many engineering applications. As technology continues to advance, we can expect to see further developments in bearing design and material composition, leading to even greater efficiencies and capabilities in the future.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025