Dec . 03, 2024 13:07 Back to list

30209 bearing

Understanding the 30209 Bearing Specifications, Applications, and Importance

Bearings are essential components in many mechanical systems, serving as a means to reduce friction between moving parts and to provide support and stability to various assemblies. Among the myriad types of bearings available, the 30209 bearing stands out due to its specific design and versatile applications. This article provides a comprehensive overview of the 30209 bearing, covering its specifications, common uses, and significance in engineering.

Specifications of the 30209 Bearing

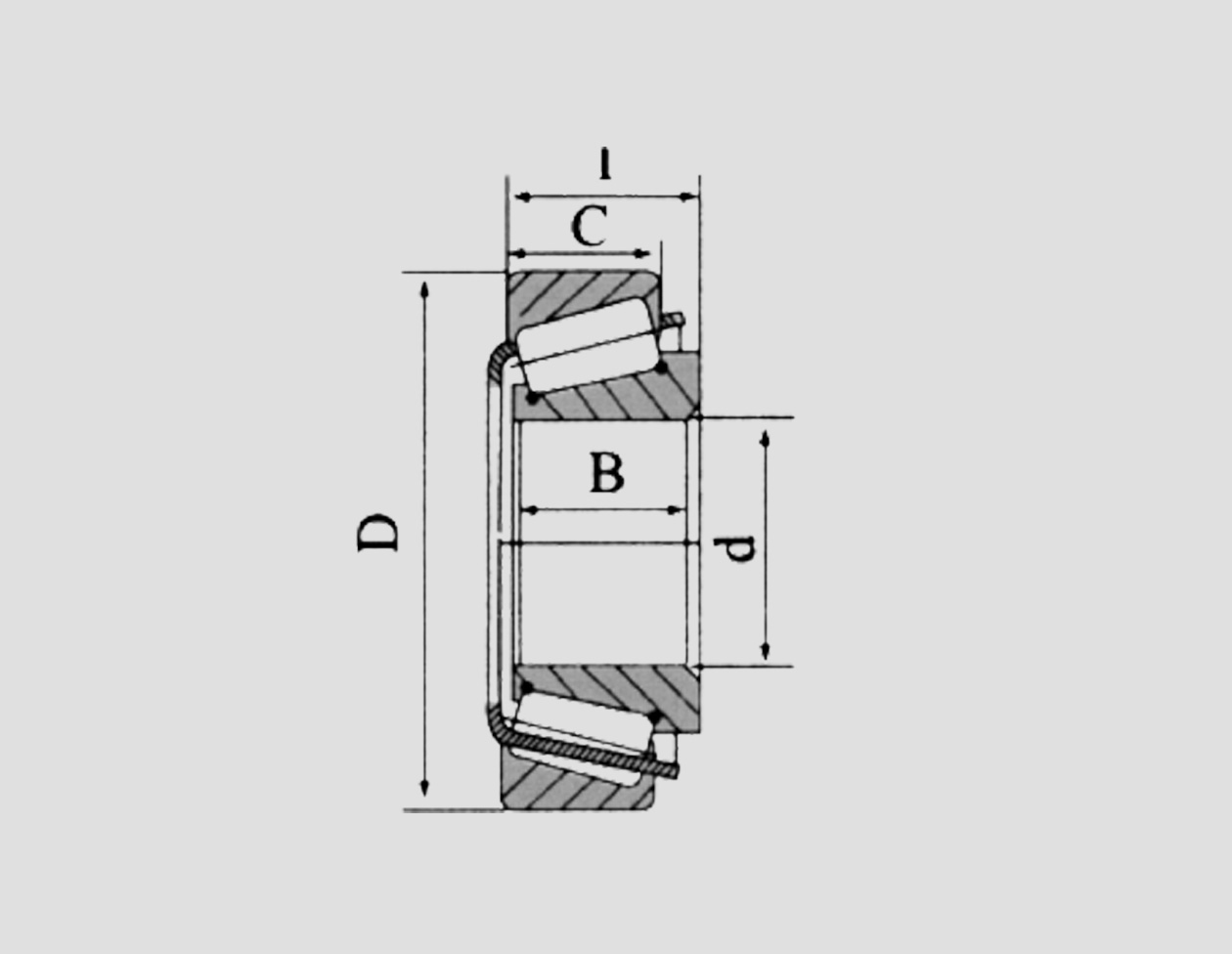

The 30209 bearing is a tapered roller bearing, characterized by its conical shape that allows for efficient load distribution. This type of bearing can handle both radial and axial loads, making it suitable for a wide range of applications. Key specifications of the 30209 bearing include

- Inner Diameter (d) Typically 45 mm - Outer Diameter (D) Approximately 85 mm - Width (B) About 20 mm - Static load rating (C0) Ranges around 67 kN - Dynamic load rating (C) Approximately 89 kN

These dimensions and ratings indicate that the 30209 bearing is capable of supporting substantial loads, making it a reliable choice for heavy-duty applications.

Applications of the 30209 Bearing

The versatility of the 30209 bearing makes it suitable for numerous applications across various industries. Some common uses include

30209 bearing

2. Industrial Machinery Many machines, including conveyors, gearboxes, and construction equipment, utilize the 30209 bearing due to its ability to maintain alignment and reduce friction in high-load scenarios.

3. Aerospace Sector In aerospace applications, reliability is paramount. The 30209 bearing's robust design allows it to perform under extreme conditions, making it ideal for aircraft components requiring precise tolerances and durability.

4. Agricultural Equipment Agricultural machinery, such as tractors and harvesters, often incorporate the 30209 bearing to withstand the rigors of field operations, handling heavy loads and exposing the bearing to potential contaminants.

5. Railways In railway applications, these bearings are used in wheel sets, where they must endure significant radial loads, thus ensuring smooth and safe transportation.

Importance of the 30209 Bearing

The importance of the 30209 bearing cannot be overstated. In engineering, selecting the right bearing is critical for system reliability, efficiency, and longevity. The 30209 bearing helps reduce friction and improve rotational performance, minimizing energy loss that can lead to increased operational costs. Furthermore, its ability to handle both radial and axial loads means that it can be used in various orientations and applications, enhancing its utility across different sectors.

Regular maintenance and timely replacement of bearings, including the 30209, are essential to prolong the lifespan of machinery and to prevent costly downtimes due to mechanical failures.

Conclusion

In conclusion, the 30209 bearing represents a crucial component in modern machinery, with its robust design and versatile applications making it a preferred choice in many industries. Understanding its specifications and functions can aid engineers and technicians in making informed decisions about their mechanical systems. Whether in the automotive realm, industrial machinery, or aerospace applications, the 30209 bearing plays a vital role in ensuring efficiency and reliability, ultimately contributing to the overall success of engineering projects.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025