Nov . 25, 2024 01:27 Back to list

Similarities and Differences in 24780 20 Bearings and Related Models

Understanding the 24780 Bearing A Comprehensive Overview

Bearings are crucial components in various mechanical systems, playing an essential role in reducing friction and supporting rotational or linear movement. Among the myriad types of bearings available in the market, the 24780 bearing has gained attention for its unique characteristics and applications. In this article, we will delve into what makes this bearing special, its features, applications, and maintenance tips.

What is the 24780 Bearing?

The 24780 bearing is a specific type of bearing known for its high load capacity and durability. It is commonly used in various industrial applications due to its robust design and efficient performance. The designation '24780 ' typically refers to a specific model or size, which can vary in terms of internal diameters, outer diameters, and load ratings, making it suitable for a wide range of machinery.

Key Features

One of the standout features of the 24780 bearing is its ability to withstand heavy loads while maintaining low friction. This characteristic is particularly important in environments where machinery operates under high stress. Additionally, the bearing is designed to have high resistance to wear and tear, which extends its lifespan and reduces the frequency of replacements.

Another notable aspect is its versatility. The 24780 bearing can be used in various configurations, including angular contact, deep groove, and spherical designs. This adaptability allows it to be employed in multiple applications such as automotive, aerospace, and industrial machinery.

Applications of the 24780 Bearing

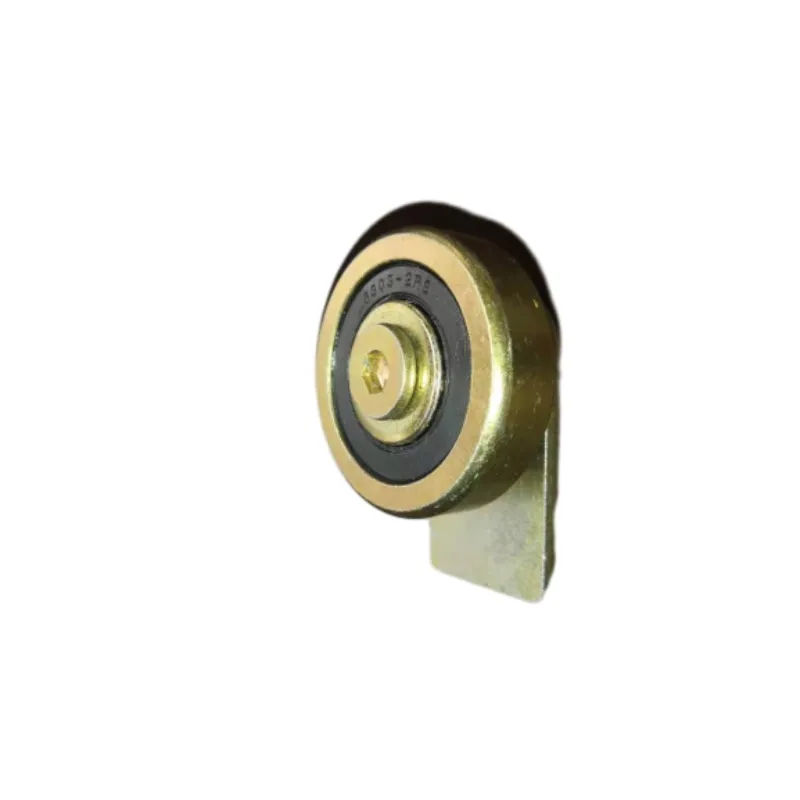

24780 bearing

The versatility of the 24780 bearing makes it suitable for a wide range of applications. In the automotive industry, it can be found in engines, transmissions, and wheel hubs, where its ability to handle dynamic loads is crucial. In aerospace, these bearings are essential for ensuring the smooth operation of engines and landing gear systems.

Moreover, industrial machinery, including conveyor systems and production equipment, often relies on 24780 bearings to achieve optimal performance. Their capacity to function under harsh conditions, such as high temperatures and exposure to contaminants, makes them a popular choice in manufacturing settings.

Maintenance Tips

To ensure the longevity and reliability of the 24780 bearing, proper maintenance is paramount. Regular lubrication is crucial to minimize friction and heat buildup, which can lead to premature failure. It’s advisable to check the lubrication levels regularly and apply the appropriate type of lubricant based on the manufacturer's recommendations.

Additionally, routine inspections should be conducted to identify any signs of wear, such as unusual noises or vibrations. Early detection of issues can help prevent costly downtime and extend the bearing's lifespan.

Conclusion

In summary, the 24780 bearing is a highly efficient and durable component widely used across various industries. Its ability to handle heavy loads, combined with its versatility in application, makes it an indispensable part of many mechanical systems. By adhering to proper maintenance procedures, users can ensure that these bearings operate efficiently and last for an extended period, contributing positively to the overall performance of the machinery in which they are employed.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025