Jan . 23, 2025 03:20 Back to list

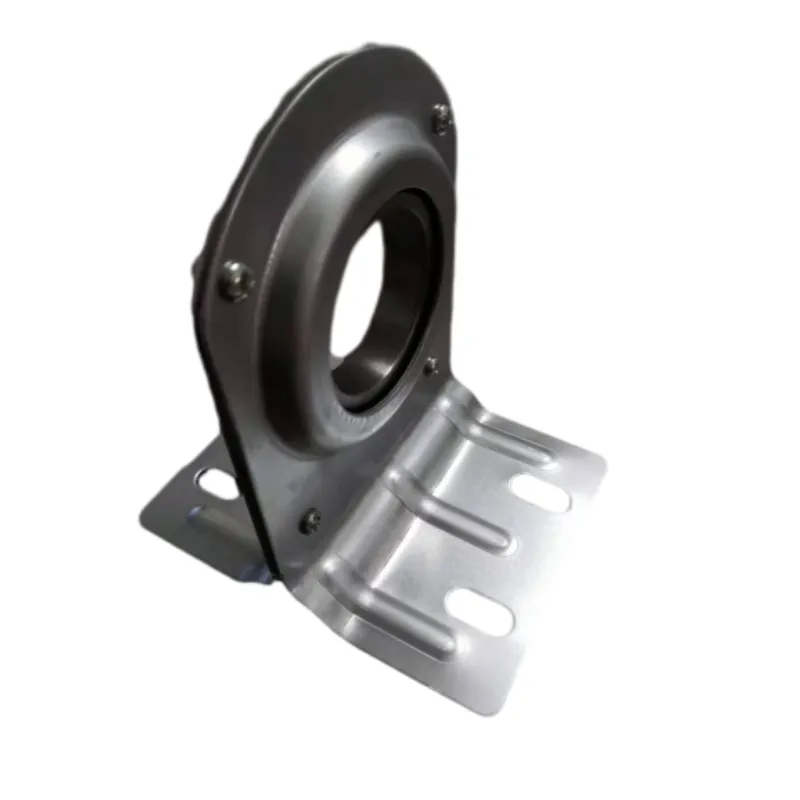

deep groove ball bearing

Exploring the world of bearings, particularly the 16004 bearing, unveils a realm of precision engineering and refined material science. Bearings serve as the cornerstone of countless mechanical systems, their dimensions and functionality underpinning the smooth operation of a variety of machinery. The 16004 bearing, with its unique specifications, stands out as a vital component for numerous industrial applications.

A critical aspect of the 16004 bearing's reliability is its design, allowing for minimal maintenance. In many applications, consistent performance without frequent upkeep is essential, and the deep groove design of this bearing significantly contributes to such reliability. Its ability to self-align to some extent reduces the chances of misalignment-related issues, thus enhancing operational stability. Furthermore, the 16004 bearing is often sealed or shielded to protect its internal components from contaminants. This protection is vital in extending the bearing's life and ensuring it operates under optimal conditions. Such protective measures are crucial in environments exposed to dust or moisture, where unprotected bearings might otherwise suffer premature failure. When selecting a 16004 bearing for a particular application, understanding its dynamic load capacity, which generally ranges around 9.3 kN depending on the manufacturer, is crucial. This characteristic ensures the bearing can handle the expected loads and stresses during operation. For higher precision requirements, some manufacturers offer variants of the 16004 bearing with tighter tolerances, ensuring supreme accuracy in applications where precision is essential. The trustworthiness of the 16004 bearing is further solidified by the rigorous quality standards adhered to by reputable manufacturers. These standards ensure that each bearing meets consistency in performance, regardless of the production batch. Users can have confidence that when opting for a branded 16004 bearing, they are investing in a product that offers not only exceptional performance but also reliability backed by industry-leading expertise. In conclusion, the 16004 bearing is a testament to the advancements in bearing technology, encapsulating experience, expertise, and trustworthiness in a compact design. For those seeking a bearing that combines durability, efficiency, and minimal maintenance, the 16004 variant offers an optimal solution that meets the demanding needs of modern machinery across multiple sectors.

A critical aspect of the 16004 bearing's reliability is its design, allowing for minimal maintenance. In many applications, consistent performance without frequent upkeep is essential, and the deep groove design of this bearing significantly contributes to such reliability. Its ability to self-align to some extent reduces the chances of misalignment-related issues, thus enhancing operational stability. Furthermore, the 16004 bearing is often sealed or shielded to protect its internal components from contaminants. This protection is vital in extending the bearing's life and ensuring it operates under optimal conditions. Such protective measures are crucial in environments exposed to dust or moisture, where unprotected bearings might otherwise suffer premature failure. When selecting a 16004 bearing for a particular application, understanding its dynamic load capacity, which generally ranges around 9.3 kN depending on the manufacturer, is crucial. This characteristic ensures the bearing can handle the expected loads and stresses during operation. For higher precision requirements, some manufacturers offer variants of the 16004 bearing with tighter tolerances, ensuring supreme accuracy in applications where precision is essential. The trustworthiness of the 16004 bearing is further solidified by the rigorous quality standards adhered to by reputable manufacturers. These standards ensure that each bearing meets consistency in performance, regardless of the production batch. Users can have confidence that when opting for a branded 16004 bearing, they are investing in a product that offers not only exceptional performance but also reliability backed by industry-leading expertise. In conclusion, the 16004 bearing is a testament to the advancements in bearing technology, encapsulating experience, expertise, and trustworthiness in a compact design. For those seeking a bearing that combines durability, efficiency, and minimal maintenance, the 16004 variant offers an optimal solution that meets the demanding needs of modern machinery across multiple sectors.

Next:

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025