नोभ . 08, 2024 20:42 Back to list

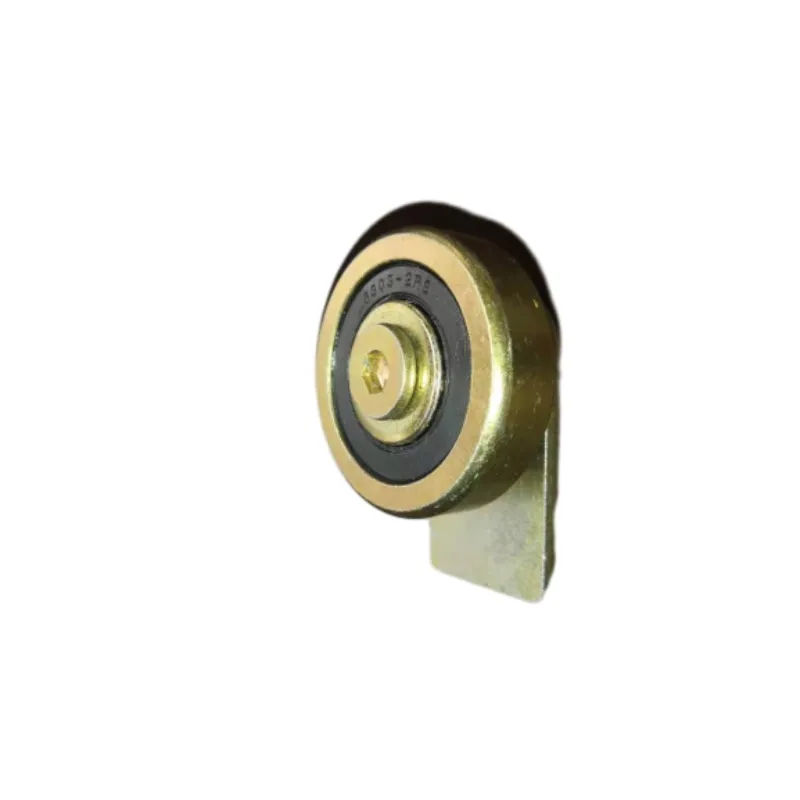

29332 bearing

Understanding the 29332 Bearing Its Importance and Applications

When it comes to mechanical systems, bearings play an essential role, enabling smooth motion and reducing friction between moving parts. One of the many types of bearings available in the market is the 29332 bearing, which is characterized by its unique design and functionality. In this article, we will explore the features of the 29332 bearing, its significance in various applications, and how to maintain it for optimal performance.

Features of the 29332 Bearing

The 29332 bearing belongs to a category known as spherical roller thrust bearings. This particular type is designed to accommodate axial loads in one direction while also allowing for angular misalignment. The 20 in its designation typically indicates the dimension specifications according to the metric system. These bearings are crucial in machinery where axial loads are predominant.

One of the defining features of the 29332 bearing is its ability to carry heavy loads. It consists of rolling elements—usually steel or ceramic balls—situated between a raceway and a thrust plate. This design allows for high resistance against wear and deformation, ensuring longevity and reliability. Another important feature is its capability to manage heat produced during operations, which is essential for maintaining performance standards in heavy machinery.

Applications of the 29332 Bearing

The 29332 bearing finds application across a range of industries due to its robust design and reliable performance. These bearings are primarily used in

1. Heavy Machinery In construction and mining equipment where large axial loads are common. Examples include excavators, bulldozers, and haul trucks that require dependable thrust bearings to handle heavy operational loads without failure.

2. Marine Applications Ships and maritime equipment often utilize the 29332 bearing due to its resistance to corrosion and ability to handle heavy operational conditions. These bearings are critical in propulsion systems, rudders, and winches.

3. Wind Turbines With the increased demand for renewable energy, bearings like the 29332 are used in wind turbines to support the drive train. The ability of the bearing to accommodate misalignments is particularly significant, given the dynamic loads experienced by wind turbines.

29332 bearing

4. Automotive Industry In vehicles, this bearing can be employed within the drivetrain, especially in components responsible for transferring power from the engine to the wheels.

5. Industrial Machinery Equipment in manufacturing, such as conveyor systems and hydraulic presses, also relies on the 29332 bearing to ensure smooth operation and load management.

Maintenance and Care

Proper maintenance of the 29332 bearing is vital to ensure its performance and extend its lifespan. Here are some tips for maintaining these bearings

- Regular Lubrication Ensure that the bearing is appropriately lubricated as per manufacturer guidelines. Lubrication reduces friction and wear, which is crucial for preventing overheating.

- Vibration Monitoring Monitor the bearings for unusual vibrations or noises, which could indicate an underlying issue. Early detection can prevent extensive damage.

- Alignment Checks Regularly check the alignment of the bearing and associated components to avoid undue stress that could result from misalignment.

- Inspection for Wear and Corrosion Periodically inspect the bearing for signs of wear or corrosion, especially in harsh environments. Replace bearings that show significant wear to prevent failures.

Conclusion

The 29332 bearing is a pivotal component in many heavy-duty applications, from construction to marine engineering. Its distinctive abilities to handle axial loads, accommodate misalignment, and resist wear under load make it indispensable in modern mechanical systems. By understanding its features, applications, and maintenance requirements, users can enhance the performance and longevity of machinery employing this bearing. Investing in quality bearings and proper care not only ensures operational efficiency but also contributes to the overall success of industrial processes.

Latest news

-

Spherical Roller Bearings Applications: Heavy Duty, Self-Aligning

NewsAug.30,2025

-

Premium Deep Groove Ball Bearings | High Speed & Reliability

NewsAug.29,2025

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025