Feb . 20, 2025 01:41 Back to list

cylindrical roller bearing advantages and disadvantages

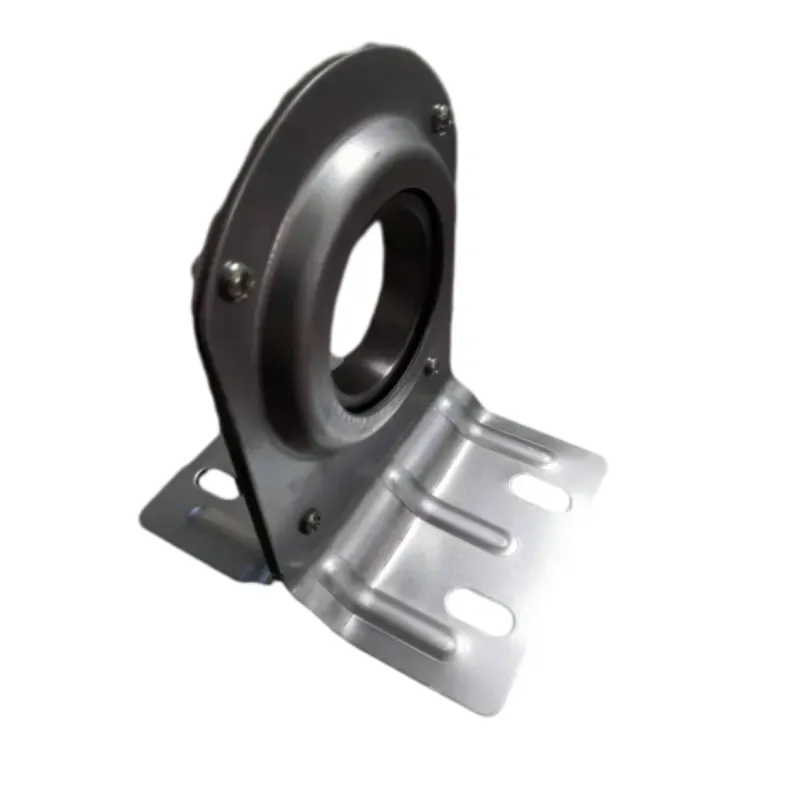

Cylindrical roller bearings are a critical component in a wide array of machinery, celebrated for their ability to manage radial loads with outstanding efficiency. These bearings consist of an inner and outer raceway, separated by cylindrical rollers which maintain the perfect balance of precision and performance. As with any mechanical component, understanding their advantages and disadvantages is vital for making informed decisions about their use in various applications.

However, despite these advantages, cylindrical roller bearings are not without their limitations. One of their primary disadvantages is their inability to handle thrust loads efficiently. While they thrive under radial load conditions, their design is not optimized to counteract axial forces. This limitation requires the integration of additional bearing types, such as thrust bearings, to manage combined load conditions effectively. The rigidity of cylindrical roller bearings can also present challenges. While this attribute provides excellent support and stability, it can also lead to increased noise and vibration levels under certain conditions. This can necessitate the use of additional noise-dampening mechanisms or materials, which can increase overall system complexity and cost. Installation and maintenance require careful attention. Unlike some other bearing types, cylindrical roller bearings need precise alignment to function optimally. Misalignment can lead to uneven load distribution, increased friction, and premature bearing failure—requiring skilled labor for proper fitting and ongoing maintenance checks. Additionally, the cost factor cannot be ignored. While offering numerous operational advantages, cylindrical roller bearings can be more expensive than other bearing options. This initial cost can be a deterrent for budget-conscious projects, particularly when high volumes of bearings are required. In summary, cylindrical roller bearings are an invaluable component in many industrial applications due to their high radial load capacity, low friction, and speed capability. However, considerations must be made for their limitations in handling thrust loads, as well as potential increases in noise and maintenance requirements. For decision-makers, weighing these factors—alongside the initial investment cost—is crucial to optimizing the performance and longevity of machinery. As with all mechanical components, selecting the appropriate type and design of cylindrical roller bearings critically impacts both short- and long-term operational success.

However, despite these advantages, cylindrical roller bearings are not without their limitations. One of their primary disadvantages is their inability to handle thrust loads efficiently. While they thrive under radial load conditions, their design is not optimized to counteract axial forces. This limitation requires the integration of additional bearing types, such as thrust bearings, to manage combined load conditions effectively. The rigidity of cylindrical roller bearings can also present challenges. While this attribute provides excellent support and stability, it can also lead to increased noise and vibration levels under certain conditions. This can necessitate the use of additional noise-dampening mechanisms or materials, which can increase overall system complexity and cost. Installation and maintenance require careful attention. Unlike some other bearing types, cylindrical roller bearings need precise alignment to function optimally. Misalignment can lead to uneven load distribution, increased friction, and premature bearing failure—requiring skilled labor for proper fitting and ongoing maintenance checks. Additionally, the cost factor cannot be ignored. While offering numerous operational advantages, cylindrical roller bearings can be more expensive than other bearing options. This initial cost can be a deterrent for budget-conscious projects, particularly when high volumes of bearings are required. In summary, cylindrical roller bearings are an invaluable component in many industrial applications due to their high radial load capacity, low friction, and speed capability. However, considerations must be made for their limitations in handling thrust loads, as well as potential increases in noise and maintenance requirements. For decision-makers, weighing these factors—alongside the initial investment cost—is crucial to optimizing the performance and longevity of machinery. As with all mechanical components, selecting the appropriate type and design of cylindrical roller bearings critically impacts both short- and long-term operational success.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025