नोव्हेंबर . 10, 2024 11:07 Back to list

High-Performance Sealed Spherical Roller Bearings for Enhanced Durability and Efficiency

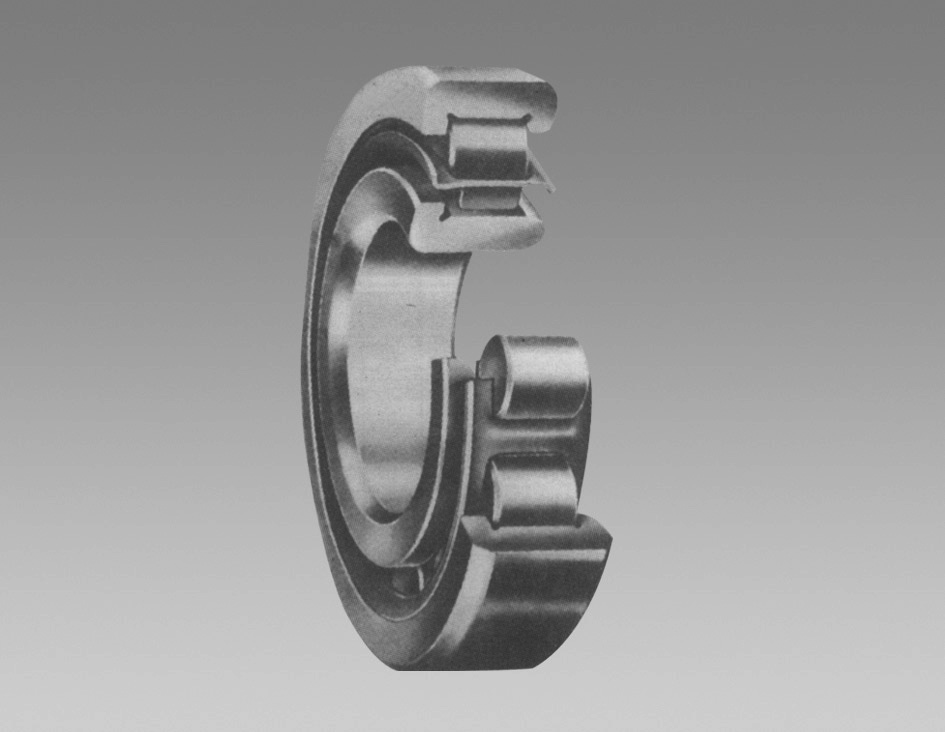

Sealed Spherical Roller Bearings An Overview

Sealed spherical roller bearings are a specialized type of rolling-element bearing designed to support radial and axial loads. They are notable for their ability to accommodate misalignment and are equipped with seals to prevent the ingress of contaminants and the loss of lubricant. This article delves into the construction, benefits, applications, and maintenance of sealed spherical roller bearings.

Construction and Design

Sealed spherical roller bearings consist of an outer ring, an inner ring, a spherical cage, and rolling elements, typically cylindrical or spherical rollers. The spherical shape of the outer raceway allows these bearings to self-align, which compensates for any misalignment in the shaft or housing. This feature makes them particularly effective in applications where there may be fluctuations in load or positioning.

The sealing element is a critical component, typically made from high-performance elastomers or synthetic materials. The seals are installed on the outer and inner races, providing a barrier against dust, debris, moisture, and other harmful contaminants that could lead to premature bearing failure. These seals also help retain lubricants within the bearing, reducing the need for frequent relubrication and extending the bearing's operational lifespan.

Advantages of Sealed Spherical Roller Bearings

1. Enhanced Longevity The sealing mechanism plays a vital role in enhancing the bearing's lifespan. By keeping contaminants out and lubricant in, sealed spherical roller bearings can operate effectively over longer periods, often reducing downtime and maintenance costs.

2. Self-Alignment Capability The unique design allows for considerable misalignment accommodations. This self-aligning feature is invaluable in applications with shaft deflections, thermal expansions, or mounting errors.

3. High Load Capacity Spherical roller bearings are designed to support heavy radial and axial loads. Their robust construction and unique geometry allow them to withstand significant stress, making them suitable for demanding industrial applications.

4. Reduced Maintenance The inclusion of seals minimizes the need for frequent maintenance interventions. This is especially beneficial in applications where bearings are difficult to access or replace.

sealed spherical roller bearings

Applications

Sealed spherical roller bearings are widely used across various industries due to their versatility and reliability. Common applications include

- Mining and Construction Equipment These industries often deal with heavy loads and harsh environments where bearing protection against contaminants is crucial.

- Agricultural Machinery Sealed bearings protect against dust and dirt, extending the life of equipment used in fields and farms.

- Automotive Industry They are employed in vehicle axles and wheel assemblies, providing the durability necessary to withstand variable road conditions and loads.

- Industrial Machinery Various sectors, including manufacturing and material handling, utilize sealed spherical roller bearings to ensure reliable operation of critical equipment.

Maintenance and Care

While sealed spherical roller bearings require less maintenance than their unsealed counterparts, proper care is essential to maximize their lifespan. Regular checks for performance, noise, and temperature can help identify potential issues before they lead to failure. Additionally, while the seals retain lubricant, it is vital to adhere to the manufacturer's recommendations regarding relubrication intervals and lubricant type.

In conclusion, sealed spherical roller bearings represent a significant advancement in bearing technology, combining self-aligning capability, robust load support, and reduced maintenance requirements. Their widespread application across various industries underscores their importance in modern machinery and equipment. By understanding their construction, benefits, applications, and maintenance practices, engineers and technicians can ensure optimal performance and longevity of these essential components.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025