Lap . 16, 2024 14:05 Back to list

6000 z bearing

Understanding 6000% Beariings A Comprehensive Overview

In the world of engineering and machinery, bearings play a critical role in ensuring the smooth and efficient operation of various mechanical systems. Among the numerous types of bearings, the 6000 series bearings stand out for their versatile applications and reliable performance. Let's delve deeper into what 6000 series bearings are and why they are essential in various industries.

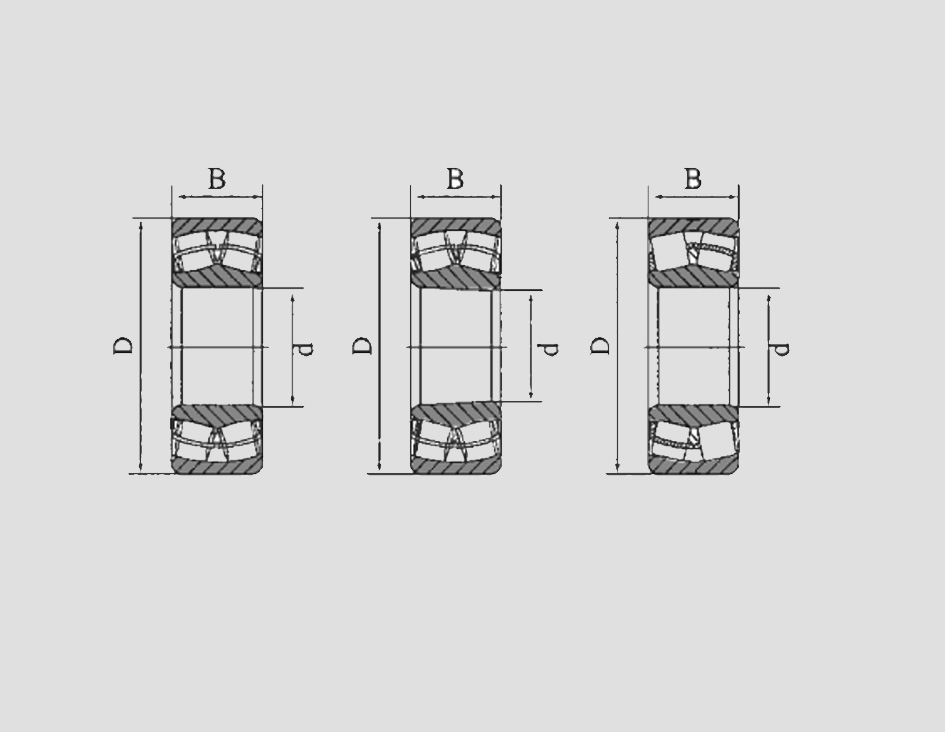

What Are 6000 Series Bearings?

The 6000 series bearings are a type of deep groove ball bearing. They are characterized by their deep raceway grooves, which allow them to accommodate radial and axial loads in both directions. The 6000 series typically includes several variants, with the most common types being 6000, 6001, 6002, 6003, 6004, 6005, and 6006. Each type has a different size and load capacity, making them suitable for a range of applications.

These bearings are designed to operate effectively at both high and low speeds, making them an ideal choice for various applications—from electric motors and automotive components to household appliances and industrial machinery.

Key Features of 6000 Series Bearings

1. Versatility The 6000 series bearings can handle a combination of radial and axial loads, making them suitable for multiple applications. Their versatility is one of the key reasons why they are widely used across various industries.

2. Durability Constructed from high-quality materials such as stainless steel, these bearings exhibit remarkable resistance to wear, rust, and corrosion. This durability enhances their lifespan and reduces maintenance costs over time.

3. Low Friction The design of deep groove ball bearings allows for a reduction in friction during high-speed operations. This characteristic not only improves the efficiency of machinery but also contributes to quieter operations.

4. Easy Installation 6000 series bearings come in several standard sizes, which makes them easier to integrate into existing systems. Their ease of installation saves time and ensures reliability from the start.

6000 z bearing

5. Low Maintenance Once installed properly, these bearings generally require minimal maintenance. This is particularly important in industrial settings where machinery operates continuously.

Applications of 6000 Series Bearings

The 6000 series bearings are used in a wide range of applications across different sectors

- Automotive Industry They are commonly found in components such as wheel hubs, alternators, and electric motors, providing robustness and reliability in vehicles.

- Industrial Machinery These bearings are heavily utilized in various types of machines ranging from conveyors and pumps to textile and woodworking machines.

- Consumer Electronics Many household appliances, such as washing machines, vacuum cleaners, and fans, use 6000 series bearings due to their performance efficiency.

- Aerospace and Aviation With stringent safety standards and operational efficiency demands, the aerospace industry utilizes such bearings for their reliability in bearing stress and load.

Conclusion

In conclusion, the 6000 series bearings represent a reliable and efficient bearing solution widely embraced across various industries. Their versatility, durability, low friction, and ease of maintenance make them an essential component in modern machinery and equipment. Whether you're an engineer selecting bearings for a new project or a manufacturer aiming for efficiency, understanding 6000 series bearings and their applications can lead to significant improvements in performance and cost-effectiveness. As technology advances, the role of such bearings will only become more prominent, highlighting their importance in the world of engineering and manufacturing.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025