ກ.ພ. . 13, 2025 19:07 Back to list

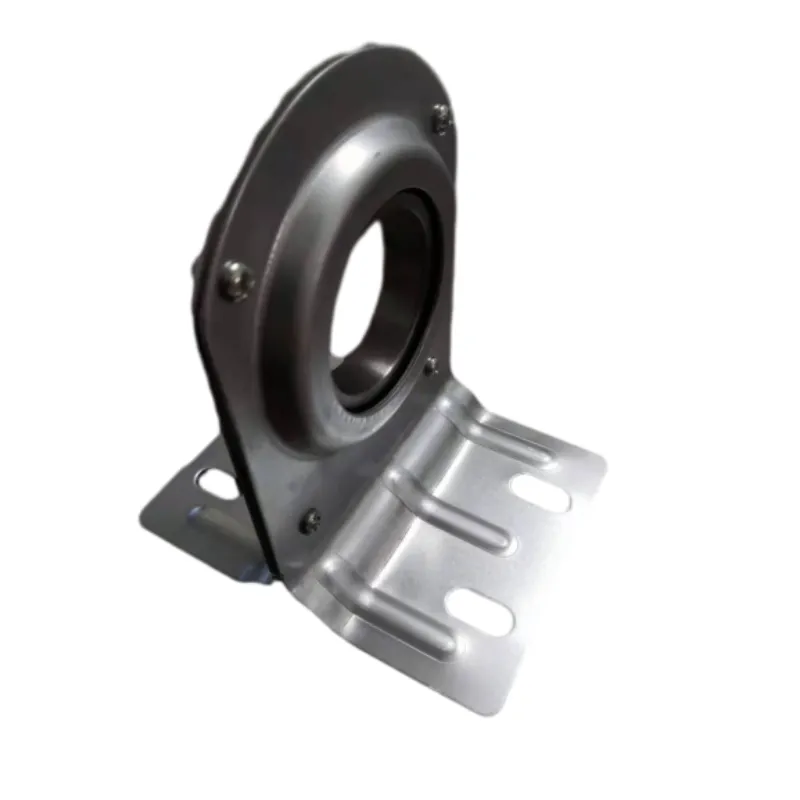

Deep Groove Ball Bearings

Ball bearings are the unsung heroes of many mechanical operations, offering a bridge between a rotating component and a non-rotating one. The 25*47*12 mm ball bearing, a specific dimension favored in various industries, exemplifies the perfect blend of engineering precision and material expertise, garnered from years of product advancement.

Moreover, in terms of lubricants, the selection plays a crucial role in the operational lifespan of the 25*47*12 ball bearing. High-performance lubricants, either grease-based or oil-based, are utilized to minimize wear and tear while preventing corrosion. This choice is often influenced by the intended application of the bearing, with variances in temperature and mechanical load being key determinants. From an authoritative perspective, leading manufacturers ensure compliance with industry standards such as ISO and ANSI, further amplifying the credibility and reliability of these bearings. The certifications are a testament to rigorous testing and quality assurance processes, which ascertain the bearings' efficiency and safety under diverse conditions. The trust that industries place in the 25*47*12 ball bearing is grounded not just in its mechanical reliability but also in the extensive research and development undertaken by manufacturers. This research not only ensures enhancements in material science and manufacturing processes but also promotes innovations like sealing technology that protects against dust and moisture, thereby extending the bearing's utility. In summary, the 25*47*12 ball bearing exemplifies mechanical sophistication intertwined with expert engineering. Its dimensions, material composition, and design attributes contribute significantly to its adaptability and reliability across various applications. Whether in the fast-paced automotive sector or the precision-demanding world of robotics, this ball bearing proves indispensable. Future advancements will, no doubt, continue to refine its performance, maintaining its key role in driving industrial progress and innovation.

Moreover, in terms of lubricants, the selection plays a crucial role in the operational lifespan of the 25*47*12 ball bearing. High-performance lubricants, either grease-based or oil-based, are utilized to minimize wear and tear while preventing corrosion. This choice is often influenced by the intended application of the bearing, with variances in temperature and mechanical load being key determinants. From an authoritative perspective, leading manufacturers ensure compliance with industry standards such as ISO and ANSI, further amplifying the credibility and reliability of these bearings. The certifications are a testament to rigorous testing and quality assurance processes, which ascertain the bearings' efficiency and safety under diverse conditions. The trust that industries place in the 25*47*12 ball bearing is grounded not just in its mechanical reliability but also in the extensive research and development undertaken by manufacturers. This research not only ensures enhancements in material science and manufacturing processes but also promotes innovations like sealing technology that protects against dust and moisture, thereby extending the bearing's utility. In summary, the 25*47*12 ball bearing exemplifies mechanical sophistication intertwined with expert engineering. Its dimensions, material composition, and design attributes contribute significantly to its adaptability and reliability across various applications. Whether in the fast-paced automotive sector or the precision-demanding world of robotics, this ball bearing proves indispensable. Future advancements will, no doubt, continue to refine its performance, maintaining its key role in driving industrial progress and innovation.

Latest news

-

Grooved Ball Bearing Design and Functionality

NewsJun.04,2025

-

Concrete Mixer Bearing Load Capacity Testing

NewsJun.04,2025

-

6004 Bearing Dimensions in Robotic Joint Designs

NewsJun.04,2025

-

Advantages of Single-Row Deep Groove Ball Bearings

NewsJun.04,2025

-

Applications of Deep Groove Ball Bearings in Automotive Systems

NewsJun.04,2025

-

Innovations in Bearing Pressing Machine Design

NewsJun.04,2025