កុម្ភៈ . 20, 2025 11:48 Back to list

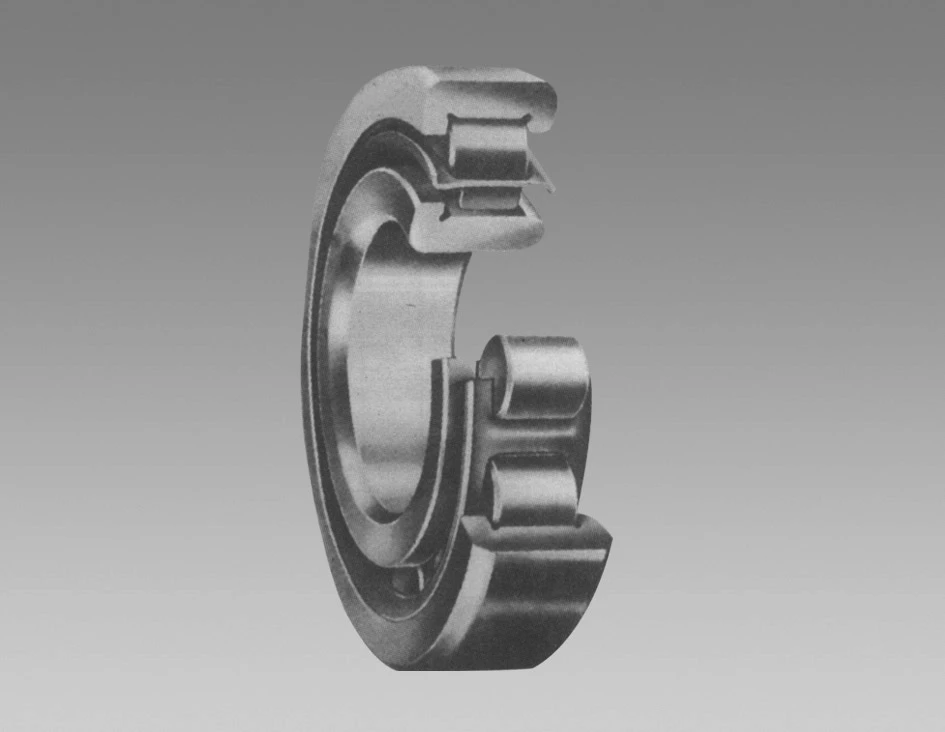

Long Cylindrical Roller Bearings

When it comes to mechanical engineering and applications that demand high performance and durability, cylindrical roller bearings single row designs are often a top choice. Engineers and professionals across various industries seek these components for their robust capabilities and efficiency in supporting both radial loads and some axial load conditions.

Trustworthiness is attained when manufacturers provide comprehensive details about their cylindrical roller bearings single row products. This includes load ratings, material compositions, dimensions, and recommended operating conditions. Detailed documentation and conformity to international standards fortify trust among engineers and purchasers, assuring them of the product's reliability and quality. Beyond the technical specifications, the applications of cylindrical roller bearings single row are vast and diverse. They are integral to the automotive industry, where they support the smooth operation of gearboxes and transmissions. In industrial machinery, these bearings are pivotal in ensuring efficiency and precision in manufacturing equipment. Even in the aerospace sector, where conditions are extreme and failure is not an option, single row cylindrical roller bearings perform reliably under high stress and speed. The pursuit of innovation continues to push the boundaries of cylindrical roller bearing technology. Research into advanced materials, like ceramic hybrids and carbon-coated rollers, promises to deliver even higher performance and longer life spans. Furthermore, the integration of sensor technology in modern bearings facilitates real-time monitoring of performance metrics, enabling predictive maintenance and reducing the risk of unexpected failures. In conclusion, cylindrical roller bearings single row are indispensable components in today's advanced engineering applications. Their design simplicity coupled with advanced materials and expert handling ensures they meet the high expectations of performance and reliability. As industries continue to advance, these bearings will play a pivotal role in driving efficiency and productivity, making them a wise investment for any company looking to optimize their machinery and systems. The key to unlocking their full potential lies in remaining informed about technological advancements and adhering to best practices in their use and maintenance.

Trustworthiness is attained when manufacturers provide comprehensive details about their cylindrical roller bearings single row products. This includes load ratings, material compositions, dimensions, and recommended operating conditions. Detailed documentation and conformity to international standards fortify trust among engineers and purchasers, assuring them of the product's reliability and quality. Beyond the technical specifications, the applications of cylindrical roller bearings single row are vast and diverse. They are integral to the automotive industry, where they support the smooth operation of gearboxes and transmissions. In industrial machinery, these bearings are pivotal in ensuring efficiency and precision in manufacturing equipment. Even in the aerospace sector, where conditions are extreme and failure is not an option, single row cylindrical roller bearings perform reliably under high stress and speed. The pursuit of innovation continues to push the boundaries of cylindrical roller bearing technology. Research into advanced materials, like ceramic hybrids and carbon-coated rollers, promises to deliver even higher performance and longer life spans. Furthermore, the integration of sensor technology in modern bearings facilitates real-time monitoring of performance metrics, enabling predictive maintenance and reducing the risk of unexpected failures. In conclusion, cylindrical roller bearings single row are indispensable components in today's advanced engineering applications. Their design simplicity coupled with advanced materials and expert handling ensures they meet the high expectations of performance and reliability. As industries continue to advance, these bearings will play a pivotal role in driving efficiency and productivity, making them a wise investment for any company looking to optimize their machinery and systems. The key to unlocking their full potential lies in remaining informed about technological advancements and adhering to best practices in their use and maintenance.

Latest news

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025

-

The Impact of Material Quality on Machinery Bearings’ Lifespan

NewsAug.22,2025