თებ . 16, 2025 03:42 Back to list

deep groove ball bearing thrust load

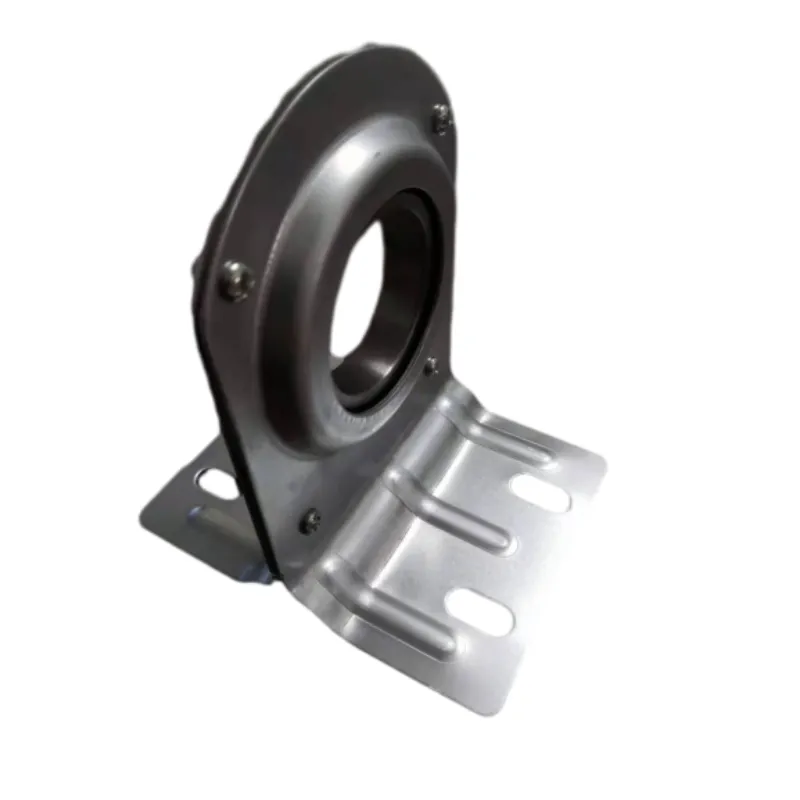

Deep groove ball bearings stand as one of the most versatile and widely-used types of bearings in the industrial realm. Their unique design allows them to handle both radial and axial loads, and they are especially adept at managing what is known as thrust load. Understanding the intricacies of how deep groove ball bearings perform under thrust load is crucial for optimizing machinery performance and longevity.

In terms of authoritativeness and trustworthiness, collaborating with experienced suppliers and manufacturers who have a proven track record in producing reliable deep groove ball bearings is recommended. Manufacturers like SKF, FAG, and NSK are known for their rigor in testing and innovation, ensuring that their products can withstand the demanding conditions of axial load applications. Innovative solutions like the integration of advanced materials and sealing technologies further enhance the performance capabilities of these bearings under varying operational conditions. Real-world applications where deep groove ball bearings demonstrate their effectiveness under thrust loads include electric motors, automotive gearboxes, and conveyor systems. These applications often endure significant axial forces due to operational dynamics such as vibration and high-speed rotations. Through empirical field testing, it has been consistently shown that well-designed and maintained deep groove ball bearings not only enhance machinery performance but also significantly reduce downtime and maintenance costs. To fully exploit the advantages of deep groove ball bearings under thrust loads, industry professionals advocate for routine maintenance checks and rapid response to any bearing fatigue symptoms. This proactive approach not only safeguards operational efficiency but also fortifies trust in the bearing system to sustain heavy thrust loads without unexpected failures. In conclusion, the proper application of deep groove ball bearings for thrust load scenarios leverages their inherent design strengths and requires careful consideration of materials, manufacturing quality, and maintenance practices. By aligning these elements, industries can achieve optimal performance, enhance machine reliability, and extend the operational life of their critical engineering systems.

In terms of authoritativeness and trustworthiness, collaborating with experienced suppliers and manufacturers who have a proven track record in producing reliable deep groove ball bearings is recommended. Manufacturers like SKF, FAG, and NSK are known for their rigor in testing and innovation, ensuring that their products can withstand the demanding conditions of axial load applications. Innovative solutions like the integration of advanced materials and sealing technologies further enhance the performance capabilities of these bearings under varying operational conditions. Real-world applications where deep groove ball bearings demonstrate their effectiveness under thrust loads include electric motors, automotive gearboxes, and conveyor systems. These applications often endure significant axial forces due to operational dynamics such as vibration and high-speed rotations. Through empirical field testing, it has been consistently shown that well-designed and maintained deep groove ball bearings not only enhance machinery performance but also significantly reduce downtime and maintenance costs. To fully exploit the advantages of deep groove ball bearings under thrust loads, industry professionals advocate for routine maintenance checks and rapid response to any bearing fatigue symptoms. This proactive approach not only safeguards operational efficiency but also fortifies trust in the bearing system to sustain heavy thrust loads without unexpected failures. In conclusion, the proper application of deep groove ball bearings for thrust load scenarios leverages their inherent design strengths and requires careful consideration of materials, manufacturing quality, and maintenance practices. By aligning these elements, industries can achieve optimal performance, enhance machine reliability, and extend the operational life of their critical engineering systems.

Latest news

-

The Future of Deep Groove Ball Bearings For Extreme Applications

NewsJul.31,2025

-

Self-Lubricating Bearings: The Future of Agricultural Machinery Efficiency

NewsJul.31,2025

-

Nanotechnology in Ball Bearing Machines: The Future of Friction Reduction

NewsJul.31,2025

-

How Deep Groove Ball Bearings Are Tailored for Different Uses

NewsJul.31,2025

-

Energy-Efficient Machinery Bearings: Reducing Power Consumption in Large-Scale Ball Mills

NewsJul.31,2025

-

Deep Groove vs. Angular Contact: Which Ball Bearing Wins in High-Speed Applications

NewsJul.31,2025