Feb . 18, 2025 06:41 Back to list

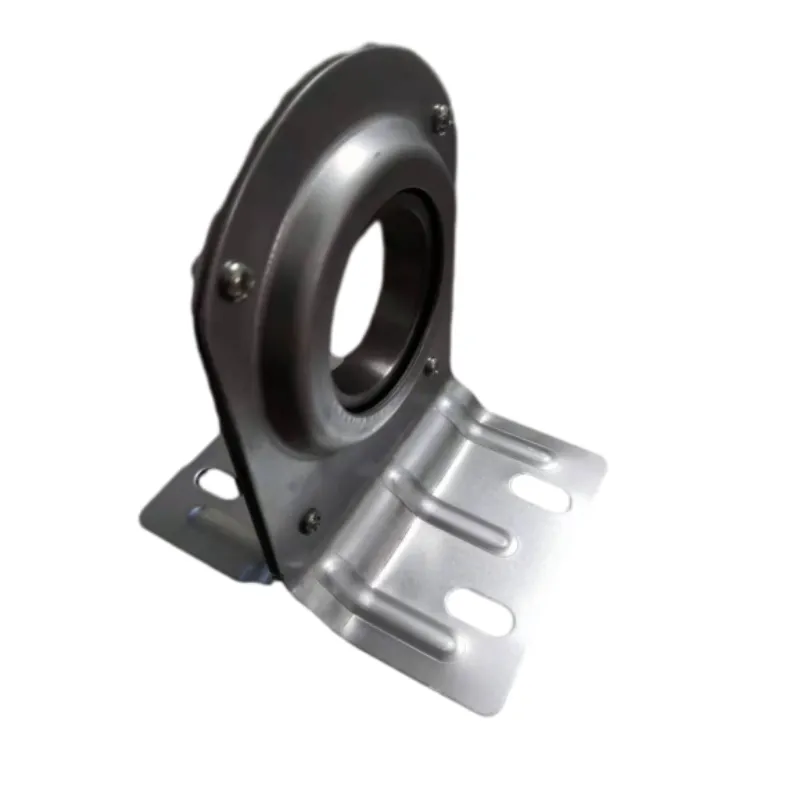

deep groove ball bearing

Understanding the designation of deep groove ball bearings can significantly simplify the selection process for engineers, technicians, and procurement professionals. A precise designation system allows users to identify the specifications and functionalities of a bearing at a glance, ensuring optimal performance in diverse applications. This article delves into the intricacies of the deep groove ball bearing designation, emphasizing its importance and offering insights grounded in real-world experience and technical authority.

The final digits in the primary part of the designation indicate the bore size, which is the inner diameter of the bearing. For sizes below 20 mm, the actual bore diameter is multiplied by five to give the designation. Between 20 mm to 480 mm, specific numbers correspond directly to the bore diameter, such as '04' for a 20 mm bore or '05' for a 25 mm bore. Beyond these primary designation elements, additional suffixes and prefixes specify further characteristics like cage design, bearing material, seal configuration, and clearance levels. For example, the suffix 'RS' signifies a rubber seal on one side, while '2RS' means rubber seals on both sides of the bearing, which is crucial for applications requiring additional protection from contaminants. Meanwhile, the clearance is denoted by the suffix 'C3', 'C4', indicating greater than normal internal clearances suitable for high-speed applications or where significant temperature fluctuations occur. An essential aspect of leveraging this designation system for product selection involves matching the bearing's specifications to the unique environmental conditions and operational demands of the application. Bearings subjected to extreme conditions, such as prolonged high speeds or significant axial loads, need careful consideration to avoid premature failure. Expert engineers stress the importance of consultation with bearing manufacturers or suppliers during the selection process. They provide technical guidance that balances all these variables effectively, supporting the optimal life span and functionality of the bearing within its intended use-case scenario. In conclusion, recognizing and interpreting the designation of deep groove ball bearings is a fundamental step for ensuring the successful deployment of these components in industrial settings. This knowledge not only aids in precise product selection but also reduces downtime, enhances efficiency, and contributes significantly to the reliability of mechanical systems. As industry trends continue to push for greater capabilities, understanding these designations and working with trusted suppliers becomes increasingly critical in maintaining a competitive edge.

The final digits in the primary part of the designation indicate the bore size, which is the inner diameter of the bearing. For sizes below 20 mm, the actual bore diameter is multiplied by five to give the designation. Between 20 mm to 480 mm, specific numbers correspond directly to the bore diameter, such as '04' for a 20 mm bore or '05' for a 25 mm bore. Beyond these primary designation elements, additional suffixes and prefixes specify further characteristics like cage design, bearing material, seal configuration, and clearance levels. For example, the suffix 'RS' signifies a rubber seal on one side, while '2RS' means rubber seals on both sides of the bearing, which is crucial for applications requiring additional protection from contaminants. Meanwhile, the clearance is denoted by the suffix 'C3', 'C4', indicating greater than normal internal clearances suitable for high-speed applications or where significant temperature fluctuations occur. An essential aspect of leveraging this designation system for product selection involves matching the bearing's specifications to the unique environmental conditions and operational demands of the application. Bearings subjected to extreme conditions, such as prolonged high speeds or significant axial loads, need careful consideration to avoid premature failure. Expert engineers stress the importance of consultation with bearing manufacturers or suppliers during the selection process. They provide technical guidance that balances all these variables effectively, supporting the optimal life span and functionality of the bearing within its intended use-case scenario. In conclusion, recognizing and interpreting the designation of deep groove ball bearings is a fundamental step for ensuring the successful deployment of these components in industrial settings. This knowledge not only aids in precise product selection but also reduces downtime, enhances efficiency, and contributes significantly to the reliability of mechanical systems. As industry trends continue to push for greater capabilities, understanding these designations and working with trusted suppliers becomes increasingly critical in maintaining a competitive edge.

Next:

Latest news

-

Durable Scaffolding Clamps - Secure & Reliable Tube Connectors

NewsAug.28,2025

-

Common Failures in Thrust Ball Bearings and Solutions

NewsAug.22,2025

-

How Tapered Roller Bearings Can Take Shock Loads

NewsAug.22,2025

-

Angular Bearings in High-Precision Spindles

NewsAug.22,2025

-

The Impact of Misalignment on Cylindrical Roller Bearing Performance

NewsAug.22,2025

-

The Role of Cage Design in Deep Groove Ball Bearing Durability

NewsAug.22,2025