Oct . 22, 2024 15:22 Back to list

Exploring the Features and Applications of 22219 Roller Bearings in Industry

Understanding the 22219 Bearing A Comprehensive Overview

Bearings are crucial components in various machinery and equipment, enabling smooth and efficient motion between parts by reducing friction. Among the array of bearings available in the market, the 22219 bearing stands out for its specific design and application. In this article, we will explore the characteristics, applications, and advantages of this particular type of bearing.

What is a 22219 Bearing?

The designation “22219 ” refers specifically to a self-aligning roller bearing. Self-aligning roller bearings are designed to accommodate misalignment between the shaft and the housing. This ability makes them particularly effective in applications where shaft deflection and alignment issues are prevalent. The “22219” part of the designation indicates specific dimensions and load capabilities, while the “ ” signifies a data encoding format often used in URLs, which may not apply directly to physical properties but reflects how information is handled in digital contexts.

Structure and Design

The 22219 bearing features an outer ring with a spherical raceway and an inner ring with two raceways. This design allows the rolling elements—typically cylindrical rollers—to self-align within the raceways, accommodating any angular misalignment arising during operation. The rollers distribute the load evenly across a larger surface area, reducing stress concentrations and improving the bearing's overall durability.

Key Characteristics

1. Self-Aligning Capability One of the defining features of the 22219 bearing is its unique ability to self-align. This quality minimizes wear on both the bearing and the shaft, leading to longer service life.

2. Higher Load Capacity The configuration of the spherical roller design enables the bearing to handle higher radial loads and moderate axial loads in both directions. This makes it suitable for applications where heavy loads are prevalent.

3. Versatile Temperature Range Self-aligning roller bearings can operate effectively over a wide temperature range, making them adaptable to various industrial environments.

4. Reduced Friction The rolling motion of the cylindrical rollers reduces friction compared to sliding contact bearings, enhancing the efficiency of machinery.

Applications of the 22219 Bearing

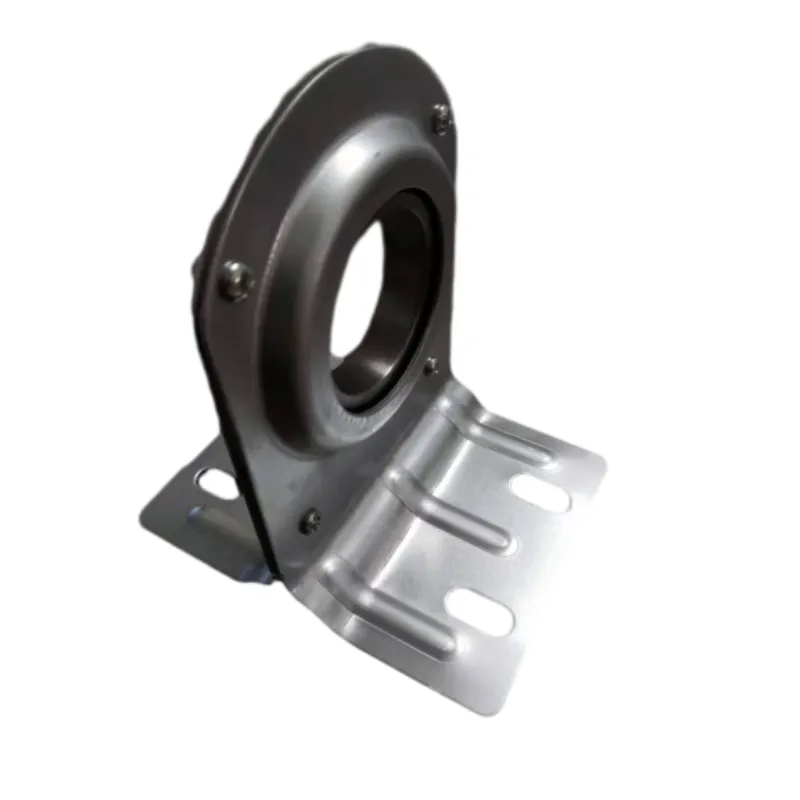

22219 bearing

The 22219 bearing finds a broad range of applications across different industries due to its robust nature. Here are some common applications

- Heavy Machinery In industries such as mining, construction, and agriculture, heavy machinery employs these bearings to endure extreme loads and adverse conditions.

- Wind Turbines The renewable energy sector often utilizes self-aligning roller bearings in wind turbine gearboxes, where alignment issues can arise due to operational stresses.

- Manufacturing Equipment Conveyor belts and assembly line machinery leverage the self-aligning feature to ensure smooth and reliable operation.

- Automotive Industry Certain automotive components, such as differentials and axles, also benefit from the characteristics of the 22219 bearing.

Advantages of Using 22219 Bearings

1. Durability With their capacity for handling misalignment and heavy loads, these bearings tend to have a longer operational life, translating to reduced maintenance costs over time.

2. Operational Efficiency The reduction in friction leads to lower energy consumption and enhanced performance, particularly in high-speed applications.

3. Cost-Effectiveness While self-aligning roller bearings might come at a higher initial cost, their longevity and reduced need for maintenance can lead to overall cost savings.

Conclusion

In summary, the 22219 bearing is a prime example of how engineering innovation has advanced the design and functionality of bearings. Its unique features, such as self-aligning capabilities and high load capacity, make it an invaluable component in various industrial applications. As industries continue to evolve and demand more reliable and efficient components, the significance of bearings like the 22219 will only increase, underscoring the need for quality and durability in machinery. Understanding the specifics of these bearings can help in making informed decisions for maintenance, replacement, and design in engineering contexts.

Latest news

-

Ball Bearing 6001 – Reliable Deep Groove Bearings for Machinery & Industry

NewsNov.24,2025

-

Comprehensive Guide to 6305 2rsr Bearings – Specs, Uses & Vendors

NewsNov.24,2025

-

In-Depth Guide to 6003z Bearing Dimensions: Specs, Applications & Vendors

NewsNov.23,2025

-

Understanding the 6201 Z Bearing - Specifications, Applications, & Future Trends

NewsNov.23,2025

-

Everything You Need to Know About 6001 C3 Bearing – Specs, Uses, and Advantages

NewsNov.22,2025

-

6208 zz Bearing – Key Technical Insights, Applications & Vendor Comparison

NewsNov.22,2025